Home » Products » NDT Ultrasonic Scanners » The XR Spider | Corrosion Mapping Scanner

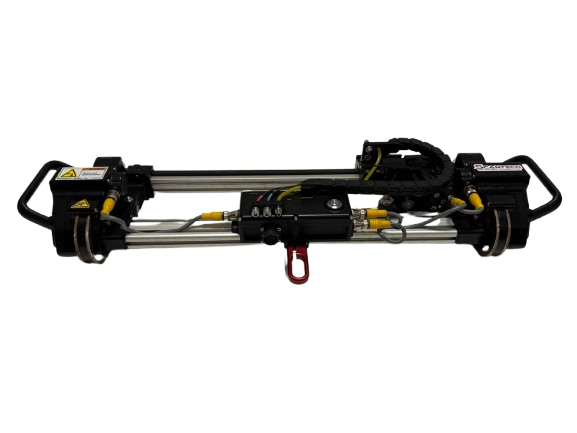

The XR is an innovative ultrasonic scanner designed for automated raster scanning. Known for its speed, stability, durability, and maneuverability, engineered to handle diverse industrial scanning applications with ease and precision.

Versatility: Capable of circumferential pipe scanning as small as 2ӯ without requiring probe adjustments.

High Maneuverability: Steering via the controller’s touch screen interface or optional wired joystick and/or Batt Pack.

High Speed: Achieves high scanning speeds without sacrificing torque and actuator force.

Durability: Custom-engineered stainless gear trains coupled directly to all four wheels in robust, a sealed enclosures for strength and low maintenance.

Automated Scanning: Delivers consistent and accurate inspection results with minimal manual intervention.

High Performance: Designed for rigorous industrial environments, ensuring reliable data collection and processing.

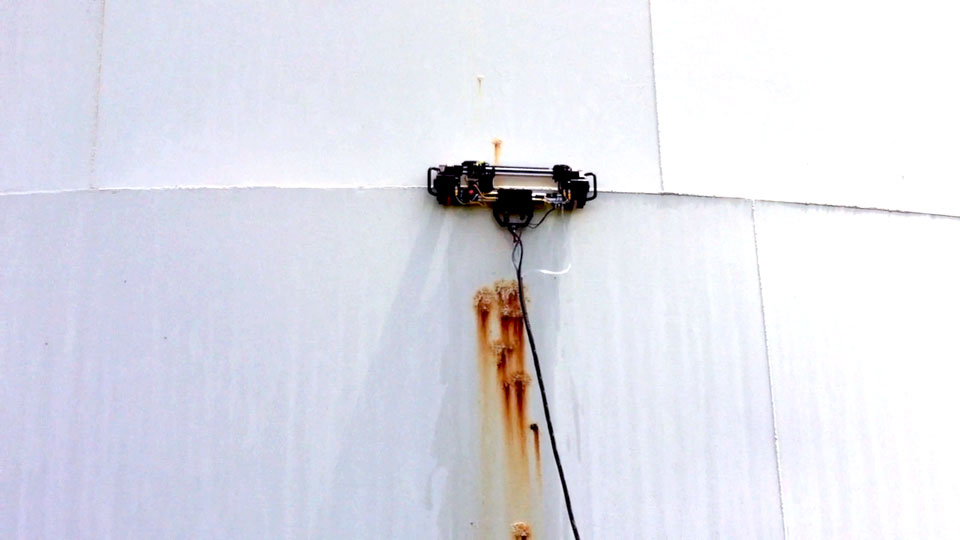

Large Storage Tanks:

Efficiently performs ultrasonic corrosion mapping on tank walls, floors, and roofs, offering high-resolution data to identify thinning and corrosion hotspots on both flat and curved surfaces.

Piping and Pipelines:

Delivers precision-guided inspections for small to large-diameter pipes, supporting axial and circumferential scans with advanced flaw detection capabilities.

Ship Hulls:

Conducts thorough ultrasonic inspections across expansive metal surfaces, accommodating complex geometries and meeting marine industry standards

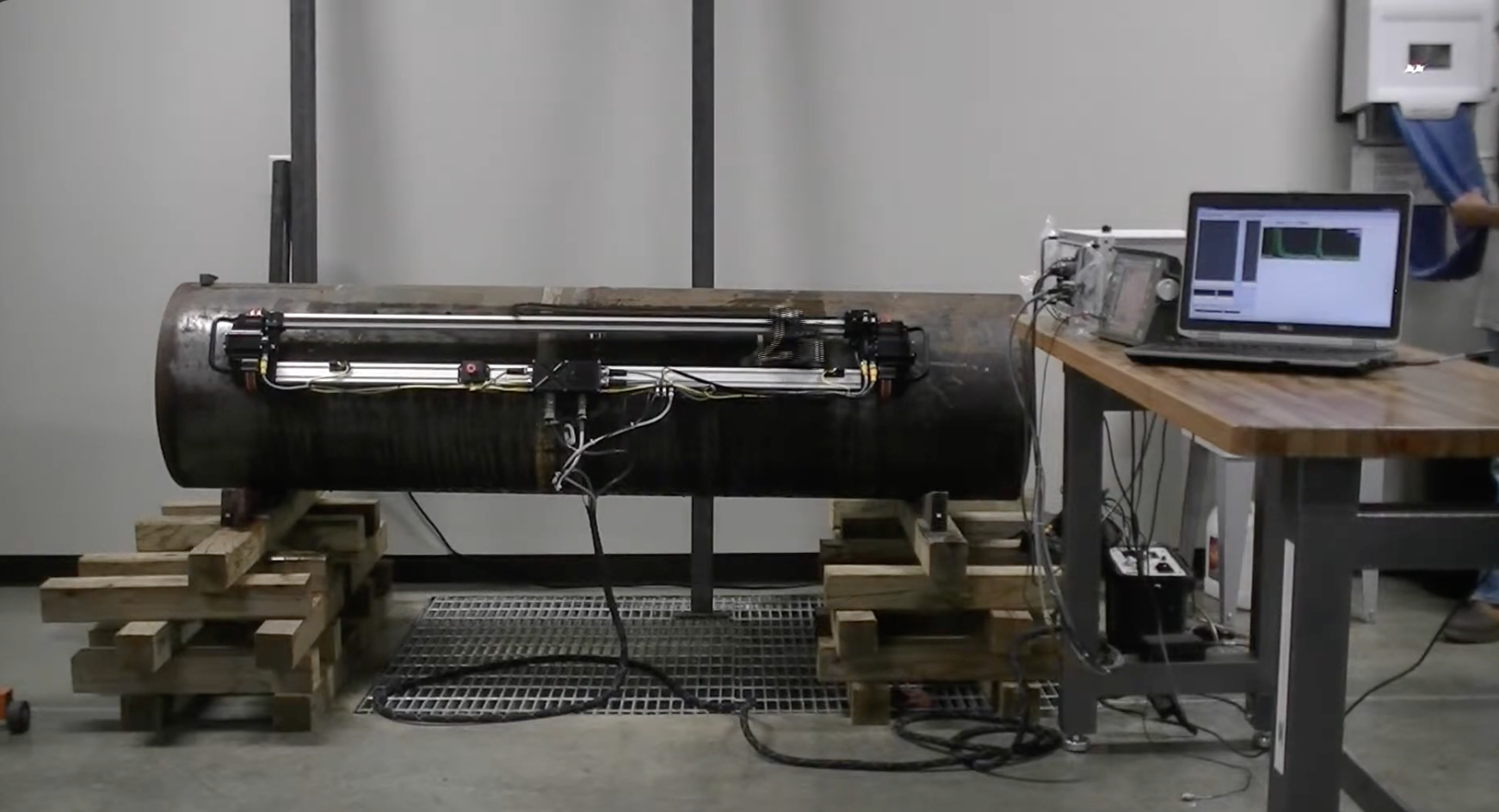

Horizontal Vessels:

Provides accurate scanning for horizontal tanks and pressure vessels, detecting localized corrosion and material loss with high-speed data acquisition.

Custom-engineered stainless steel gears with direct-coupled four-wheel drive.

Customizable stroke lengths up to 48 inches.

Engineered for rugged industrial environments.

Joystick or touch-screen steering controls for enhanced usability.

Proprietary low EMI noise motor drives for efficient operation.

No pipe diameter adjustments required, simplifying setup.

High power and torque motor drives for reliable performance.

Scanner Specifications:

Scan Arm Lengths Available: 12 in., 24 in., 34 in., 48 in. (300, 600, 870, 1200 mm)

Over-Travel: Approx. 1 in. per side (25 mm per side)

Scan Limit Protection: Homing routine

Wheel Diameter: 3.585 (91mm)

Magnetic Pull Force: 65 lbf per wheel (286 N), 260 lbf total

Scanner Weight: 26 lbs (12.2 kg) for 12 in.| 30 lbs (13.6 kg) for 24 in. | 33 lbs (14.9 kg) for 34 in. | 38 lbs (17.2 kg) for 48 in.

Dimensions (24 in Travel): 4.5 x 9.25 x 44 in. (11.5 x 23.5 x 112 cm)

Standard Transducer: Single element with water column or dual element with contact

Shoe Compliance: 10° Drive axis, 8° Scan axis, 1.75 in. vertical (45 mm)

Probe Angle Adjustments: None Required

Minimum Diameters

Circumferential Diameter: 3 in. (76.2 mm)

Axial Scan:

• 12″ Model – 20 ft Diameter

• 24″ Model – 32 ft Diameter

* Based on scanner clearance air gap on outside wheel edges, coating thickness, and surface conditions may limit diameters up to 2X limits shown due to traction considerations. For axial scanning on small diameters, see Apex.

Steering: Yes

Sealed Enclosure: Yes

Scan Axis Specifications:

Speed: 29 in./sec (736 mm/sec)

Actuator Force: 20 lbf (89 N)

Encoder Resolution: 11,053 cts/in. (435.16 cts/mm)

Drive Axis Specifications:

Speed: 13 in./sec (330 mm/sec)

Torque (Per Drive Section): 74 in./lbs. (9 Nm)

Encoder Resolution: 3,081.767 cts/in. (121.3 cts/mm)

Controller Specifications:

Power Requirement: 90-240 VAC or 12-24 VDC Battery Option

Inputs: Remote joystick cable (optional), Cat6 Ethernet cable

Outputs: Scanner control, Scanner Power, Positional Encoder

Scan Plan Input / Diagnostic Indicators: Controller

Scan Rates:

1 m x 300 mm | 1 m x 600 mm | |

10 x 10 mm | 1:11 min | 1:55 min |

5 x 5 mm | 2:15 min | 3:30 min |

2 x 2 mm | 5:21 min | 8:35 min |

1 x 1 mm | 10:36 min | 16:47 min |

Schedule a meeting with our experts to explore how our advanced NDT solutions can benefit your operations.

ScanTech Instruments has been an invaluable partner to MFE Inspection Solutions for several years, providing cutting-edge ultrasonic testing scanners that consistently deliver precision and reliability in the most challenging environments. As a leader in non-destructive testing, ScanTech's dedication to innovation and quality aligns seamlessly with MFE's commitment to offering the best inspection solutions on the market. Under the leadership of Alan Dorsey, President of ScanTech, the company has reached new heights in the inspection industry. Alan's extensive background in inspection and his deep understanding of the industry's demands have been instrumental in shaping ScanTech's product offerings to meet the evolving needs of our clients. His commitment to excellence and his hands-on experience in the field ensure that every ScanTech product is engineered with the inspector in mind, providing unmatched reliability and efficiency.

I am impressed with ScanTech’s new website and amazing new logo! The modern and intuitive design of the website makes navigation much easier and more enjoyable. Additionally, the new logo is simply spectacular, perfectly reflecting the innovation and quality that ScanTech represents.