Table of Contents

Automated ultrasonic scanners deliver high-resolution corrosion data faster, safer, and more consistently than manual scanning.

ScanTech’s corrosion mapping systems — engineered and manufactured in Longview, Texas — combine patented surface-following mechanisms, constant-force probe pressure, and integrated Analyst XR™ software to produce verifiable C-scan data with fewer rescans and faster field turnaround.

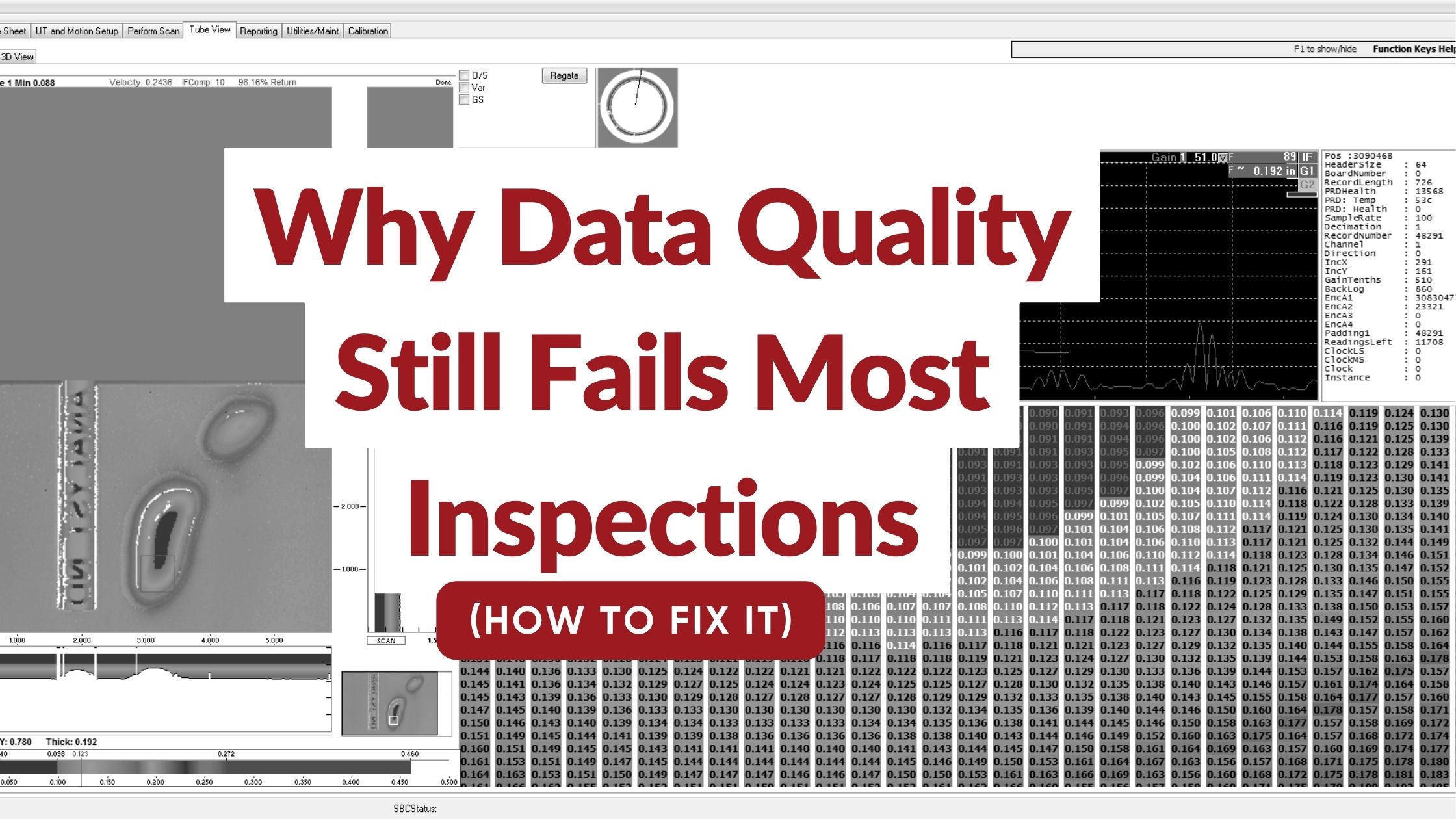

Why Corrosion Mapping Still Fails in the Field

Manual ultrasonic corrosion mapping is slow, inconsistent, and dependent on operator skill.

In refinery turnarounds, pipeline integrity surveys, and power-generation outages, the biggest costs come from data inconsistency — when poor coupling or probe angle forces rework, delaying critical repairs.

Across oil & gas, petrochemical, and power sectors, maintenance teams face the same three pain points:

- Unreliable coupling and probe contact on curved or coated surfaces.

- Slow coverage rates on large-diameter assets that extend shutdown time.

- Rising rental costs for older automated systems that require frequent recalibration or third-party support.

The result: lost time, lost trust, and data that can’t always stand up to API 653 or ASME B31G verification.

How Automated UT Changes the Workflow

Automated ultrasonic (UT) scanners perform corrosion mapping through precise raster scanning — automatically moving the probe across a defined grid to collect C-scan data.

Unlike manual B-scan passes that capture only a single thickness trace, automated corrosion mapping provides a complete, visualized corrosion profile.

Key differences vs. manual methods:

- Consistent probe pressure eliminates variability in signal response.

- Encoder accuracy ensures repeatable positioning and alignment.

- Integrated software (like ScanTech’s Analyst XR) directly calculates wall-loss rates and applies B31G algorithms for repair decisions.

By reducing human error, automated UT scanners deliver 30–50 % faster inspection coverage and a higher percentage of usable data per scan — the most critical metric in asset integrity programs.

Why Field Teams Choose ScanTech Systems

ScanTech designs and manufactures its entire line of automated scanners, electronics, and software in-house at its Texas headquarters.

Every corrosion mapping platform shares the same design DNA: rugged materials, simplified setup, and sensor precision that holds up in refinery and pipeline environments.

Engineering Advantages

- Patented Surface-Following Mechanism: Maintains flat probe contact on variable surfaces with constant-force compliance.

- Direct-Drive Assemblies: Eliminate belts and chains — preventing slippage and preserving encoder accuracy.

- Rapid Reconfiguration: Tool-free probe and wheel changes for quick adaptation between tank, pipe, or vessel scanning.

- Integrated Analyst XR Software: Real-time C-scan visualization with API 653/B31G tools built-in for on-site reporting.

Performance Proof

- 40 % faster setup than conventional magnetic scanners.

- Over 98 % data usability rate in refinery corrosion surveys (based on field test averages).

- Full ROI within two major turnaround cycles compared to recurring rental costs.

“Field-ready reliability and high data yield make automated UT one of the few technologies that pays for itself through reduced downtime.” — ScanTech Engineering Team

Recommended Systems for Corrosion Mapping

ScanTech’s corrosion mapping portfolio offers four specialized ultrasonic scanners engineered for tanks, vessels, and pipelines.

| Scanner | Description | Best For |

|---|---|---|

| APEX – Steerable Corrosion Mapping and Inline B-Scanner | Modular, steerable scanner designed for both corrosion mapping and inline B-scan inspections. Easily reconfigurable between automated and manual modes with tool-free adjustments. | Complex geometries, multi-surface scanning, and applications requiring flexibility between B-scan and C-scan. |

| XR Spider – Catamaran Corrosion Mapping Scanner | Dual-drive automated raster scanner with a compact catamaran frame and joystick or touchscreen control. Engineered for stable, high-resolution C-scan coverage across large tank and pipeline surfaces. | Large-diameter tanks, flat plates, and long pipeline runs requiring fast, consistent corrosion mapping. |

| Vertex – Non-Steerable Corrosion Mapping Scanner | Simplified corrosion mapping platform with automated drive and sealed encoder design. Compact and durable for rapid deployment and repeatable B-scan or C-scan coverage. | Pipelines, vessel shells, and environments where simplicity and durability matter most. |

| CLIX-CM – Modular Chain Scanner (Multi-Method Inspection) | Chain-based modular system compatible with both ultrasonic (UT) and digital radiography (RT) inspections. Supports infinite scan length, high payload capacity, and optional XtenDR™ DR panel holder. | Multi-method inspection workflows, especially corrosion mapping with integrated RT validation. |

Each system pairs seamlessly with Batt Pack Pro / Flex controllers and Analyst XR software, delivering repeatable, code-compliant corrosion data in less time.

Tools for Planning Your Next Inspection

Scan Time & Pass Count Calculator

Estimate raster passes and total coverage time before mobilization.

CLIX Configurator

Generate a CLIX model code for your pipe diameter, method (UT / RT), and control type — complete with compatibility notes and optional XtenDR™ accessories.

Proof That Matters

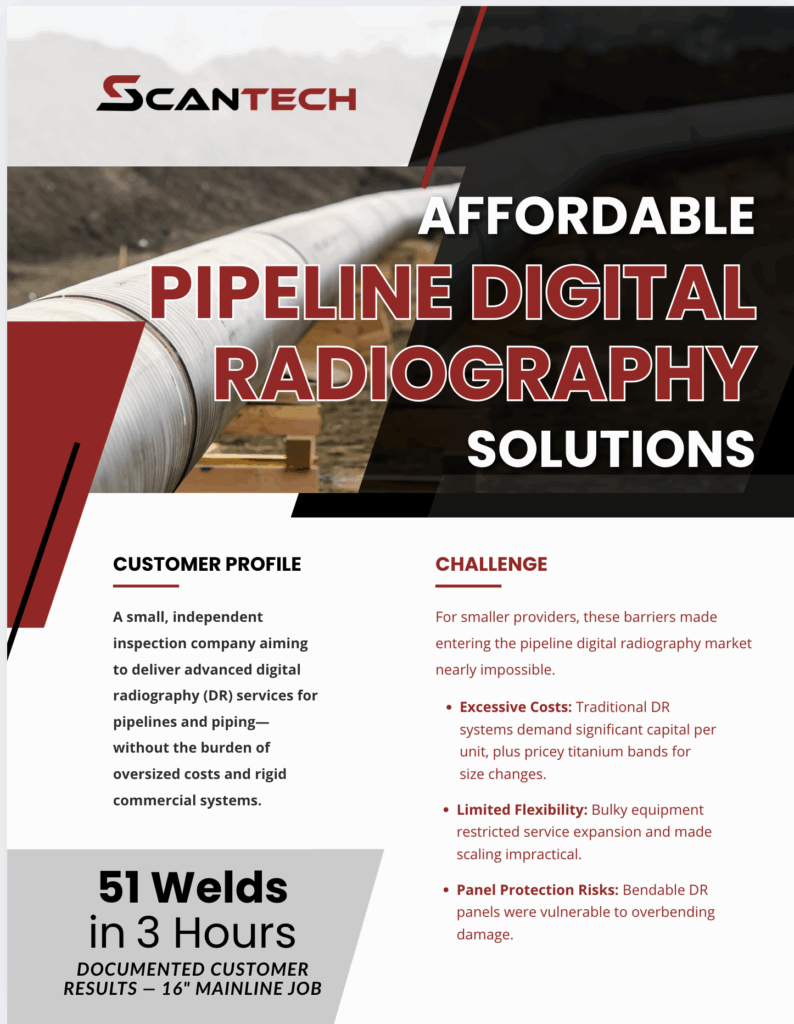

A refinery inspection service completed 51 welds in 3 hours using ScanTech’s CLIX + XtenDR configuration — cutting total setup time by nearly 40 % compared to legacy chain scanners.

That same workflow produced over 2,000 C-scan data points per hour, each auto-analyzed in Analyst XR using the built-in B31G algorithm.

Built for the Field. Engineered for Inspection.

ScanTech’s corrosion mapping scanners are not lab concepts or repackaged systems — they’re real-world tools designed by NDT technicians for refinery, pipeline, and power-generation inspections.

Next Step:

Compare Automated Scanners or Request a Field Demo