Home » Products » NDT Software » Analyst NDX ™ Software for Near Drum Scanning

Generating reports is fast and easy with Analyst NDX™. Automated reporting allows you to create templates unique to each job, ensuring efficient and repeatable reports. Drag and drop elements like scan data, screenshots, minimum points, textboxes, and logos. Customize fonts, colors, and sizes to meet specific customer needs.

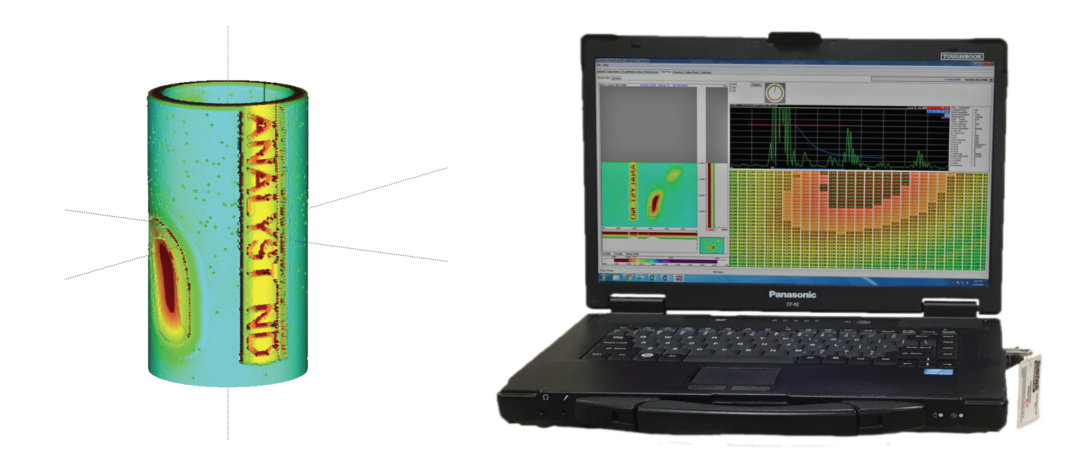

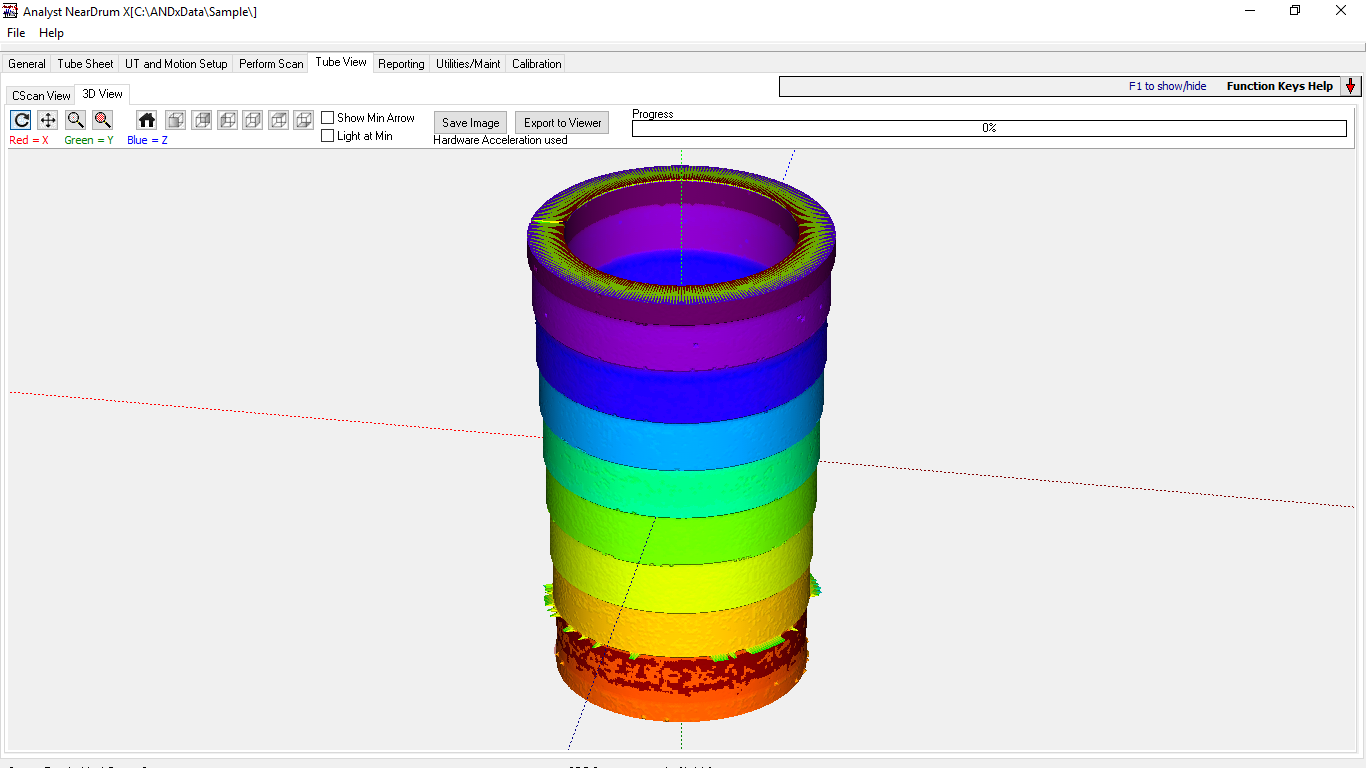

Analyst NDX™ enables the generation of a 3D model of tubes from scans. The model can be exported to an external viewer for further analysis or to be shared with customers.

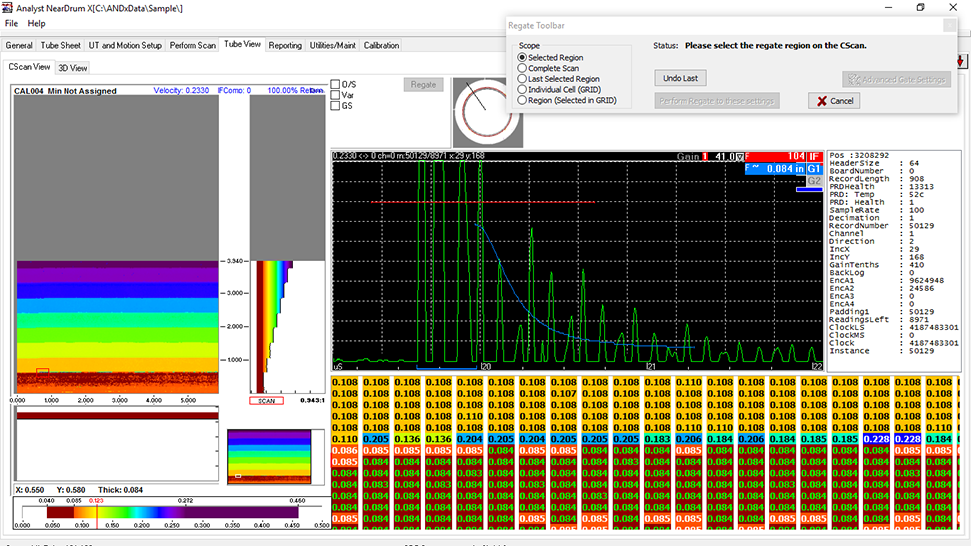

The re-gating function allows you to clean up data by re-gating a single point, region, or entire scan to reduce noise interference. Adjust the gates easily by clicking and dragging, modifying the length, height, and curvature for the most effective gate.

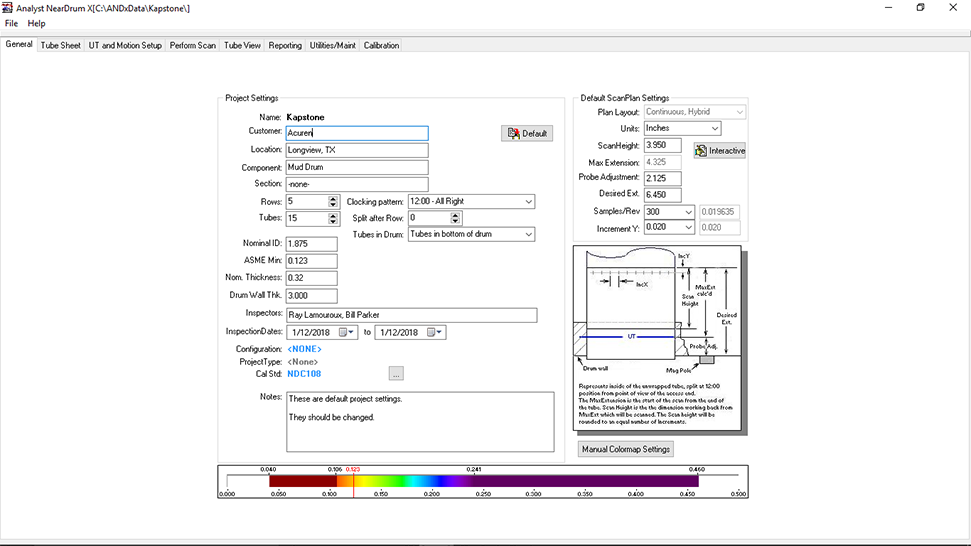

Monitor data in real-time as the scanner maps corrosion, allowing for immediate adjustments to gain during the scan for optimal results.

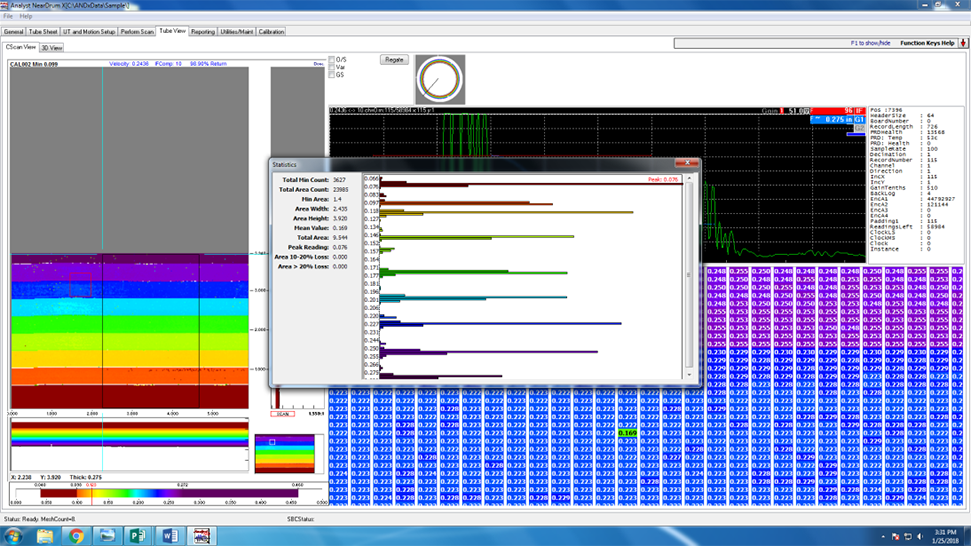

Analyst NDX™ scans a grid of data to identify the thinnest points on the vessel. It groups similar points together to exclude outliers. Use function keys to scroll through minimum points and save screenshots for the final report.

Our highly trained technicians and engineers provide comprehensive support to assist with any questions or issues that arise.

Schedule a meeting with our experts to explore how our advanced NDT solutions can benefit your operations.

ScanTech Instruments has been an invaluable partner to MFE Inspection Solutions for several years, providing cutting-edge ultrasonic testing scanners that consistently deliver precision and reliability in the most challenging environments. As a leader in non-destructive testing, ScanTech's dedication to innovation and quality aligns seamlessly with MFE's commitment to offering the best inspection solutions on the market. Under the leadership of Alan Dorsey, President of ScanTech, the company has reached new heights in the inspection industry. Alan's extensive background in inspection and his deep understanding of the industry's demands have been instrumental in shaping ScanTech's product offerings to meet the evolving needs of our clients. His commitment to excellence and his hands-on experience in the field ensure that every ScanTech product is engineered with the inspector in mind, providing unmatched reliability and efficiency.