Table of Contents

Composite materials have transformed industries such as aerospace, wind energy, and automotive. However, inspecting them is far more complex than testing metals. PAUT composite inspection—Phased Array Ultrasonic Testing for composites—has become the preferred technique for identifying delaminations, disbonds, and porosity without damaging parts.

According to the American Society for Nondestructive Testing (ASNT), composite structures present unique challenges due to variable fiber orientation and acoustic behavior. That’s why phased array methods have quickly become the go-to solution for high-value components where reliability and precision are non-negotiable.

Composites in Modern Industry

Composites combine lightweight strength with corrosion resistance, making them ideal for critical applications:

- Aerospace: aircraft wings, fuselage panels, and tail sections

- Wind Energy: turbine blades and hub housings

- Automotive: carbon fiber panels and crash structures

- Marine: hull reinforcements and hybrid structures

Each use case demands high integrity. Even minor delaminations or voids can weaken a structure. Therefore, industries now rely heavily on PAUT composite inspection for both production quality control and in-service monitoring.

For background on how ultrasonic testing works, read Ultrasonic Testing Basics.

Challenges of Testing Composite Materials

Composite inspection is not straightforward. Several material properties interfere with ultrasonic energy and data interpretation:

- Anisotropy: Sound waves travel at different speeds depending on fiber direction, causing beam bending and false depth readings.

- Attenuation: Composites absorb sound energy faster than metals, reducing penetration and clarity.

- Layer Interfaces: Adhesive joints, resin-rich zones, and trapped air reflect sound unpredictably.

- Curvature: Many composite parts are curved, adding further signal distortion.

In short, composites scatter and absorb ultrasound, which makes reliable detection harder. PAUT composite inspection solves this by steering and focusing multiple beams electronically—creating clearer data even through complex fiber layouts.

For comparison of conventional UT and phased array methods, see Phased Array in Weld Inspection.

PAUT Strategies for Composites

Technicians adapt several key strategies when performing PAUT on composite structures:

1. Calibrate on Representative Material

Always calibrate on a composite sample that matches the part’s fiber orientation and thickness. This ensures velocity and focal laws are accurate for the actual layup.

2. Use Lower Frequencies

Lower frequencies (2–5 MHz) reduce attenuation and increase penetration. While resolution decreases slightly, reliability improves for thicker laminates.

3. Optimize Focal Laws

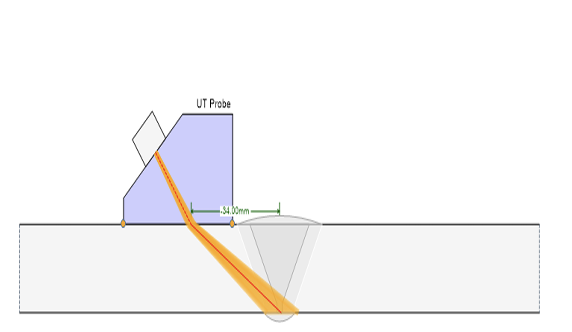

Steer beams within ±15° to ±30° to reduce distortion caused by anisotropy. Wider steering angles create unwanted noise.

4. Apply Time-Corrected Gain (TCG)

Composites attenuate unevenly with depth. TCG equalizes signal amplitudes for consistent results across the thickness.

5. Use Dual or Cross-Polar Scans

Scanning from multiple directions—or using orthogonal polarization—reveals defects missed by a single pass.

Together, these techniques make PAUT composite inspection more accurate, repeatable, and efficient.

Configurations and Techniques

Linear vs. Sector Scanning

- Linear Scans: Ideal for flat panels and uniform layups.

- Sector Scans: Better for curved parts and areas with thickness variation.

1D vs. 2D Arrays

- 1D Arrays: Compact and practical for field work.

- 2D Matrix Arrays: Capture 3D volumetric data for advanced aerospace applications.

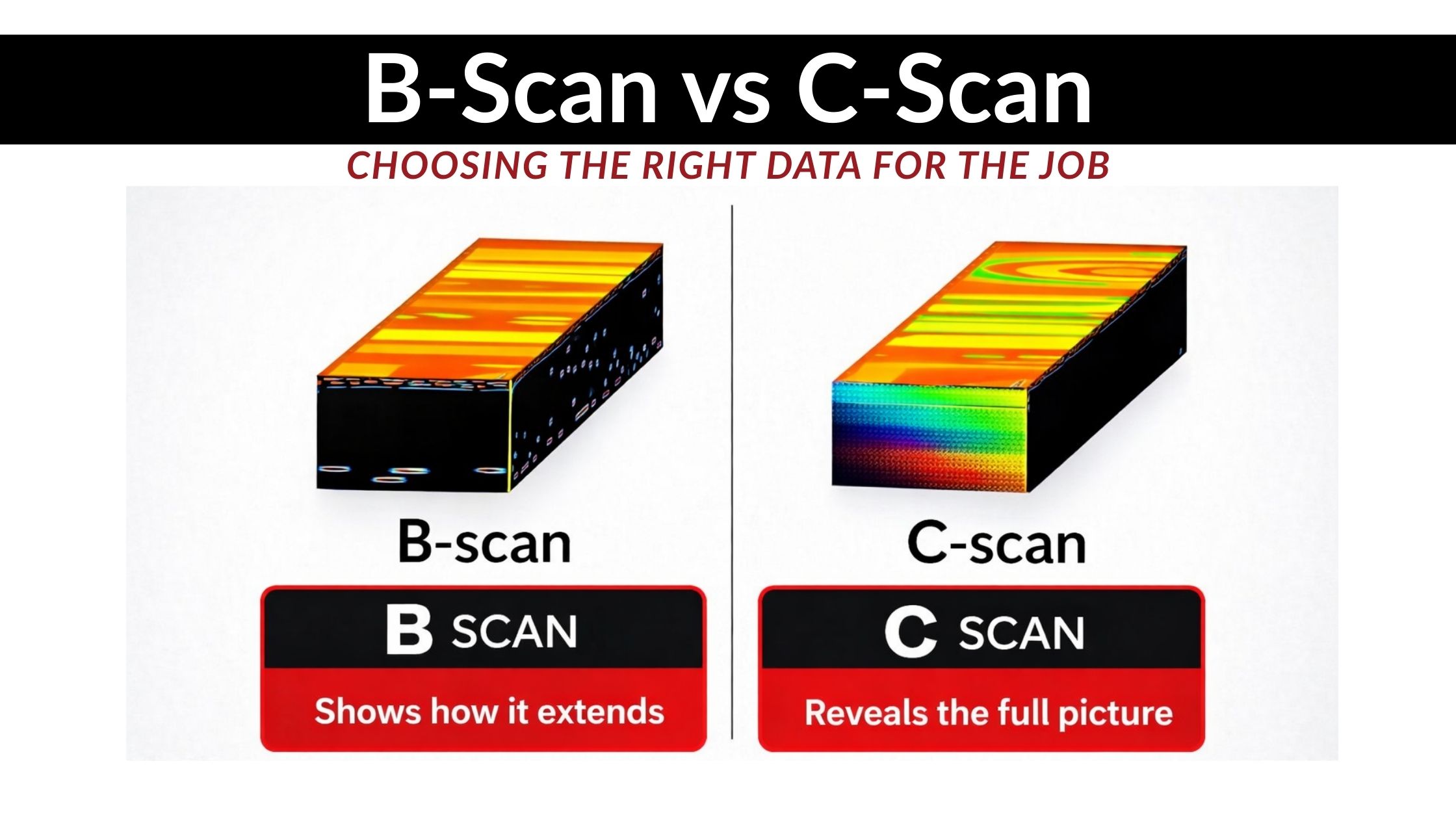

C-Scan Imaging

C-scans visualize defects as color maps, allowing engineers to assess delamination size and position at a glance.

Immersion or Water-Jet Coupling

When surface geometry is complex, a water column improves coupling, reduces signal loss, and eliminates air gaps.

These setups enable inspectors to adapt PAUT to virtually any composite component—from wind blades to aircraft fuselages.

Case Studies in PAUT Composite Inspection

Aerospace Wing Section

During an aircraft assembly check, PAUT composite inspection revealed small delaminations near rivet holes. Using a 3 MHz probe and 20° beam steering, inspectors confirmed the defect depth without dismantling the section.

Wind Turbine Blade

In the wind sector, a PAUT scan identified disbonds near the adhesive joint of a 40-meter blade. Adjusting TCG and limiting steering to ±25° helped reduce noise and locate the issue precisely.

Automotive Carbon Panel

In a racing vehicle’s carbon fiber shell, traditional UT missed fiber wrinkles. PAUT’s multi-angle scanning exposed the defect pattern, preventing a structural failure.

Each example shows how tailored setup and calibration enhance results for non-metallic, layered materials.

Limitations of PAUT in Composites

Even with its flexibility, PAUT has boundaries.

- Velocity Variations: Inconsistent fiber layups challenge precise focusing.

- High Noise Floor: Resin and void scatter increase background noise.

- Cost and Setup Time: Calibrating for each composite type requires skill and time.

- Detection Limits: Ultra-thin delaminations or in-plane defects may escape detection.

Despite these constraints, PAUT remains the most effective method for reliable non-destructive evaluation of composites used in aerospace, wind, and high-performance manufacturing.

Planning a Reliable Composite Inspection

For technicians planning an inspection program:

- Use composite-specific reference blocks.

- Select the right probe frequency and array configuration.

- Verify coupling conditions before each scan.

- Apply consistent gain, angle, and velocity settings across all data.

- Document every variable for repeatability.

PAUT composite inspection continues to evolve with new probe designs and software tools, making it indispensable for the next generation of NDT.

If you’re designing a new inspection process, start with Ultrasonic Testing Basics to review sound propagation principles. Then explore Phased Array in Weld Inspection for advanced techniques you can adapt to composites.