Table of Contents

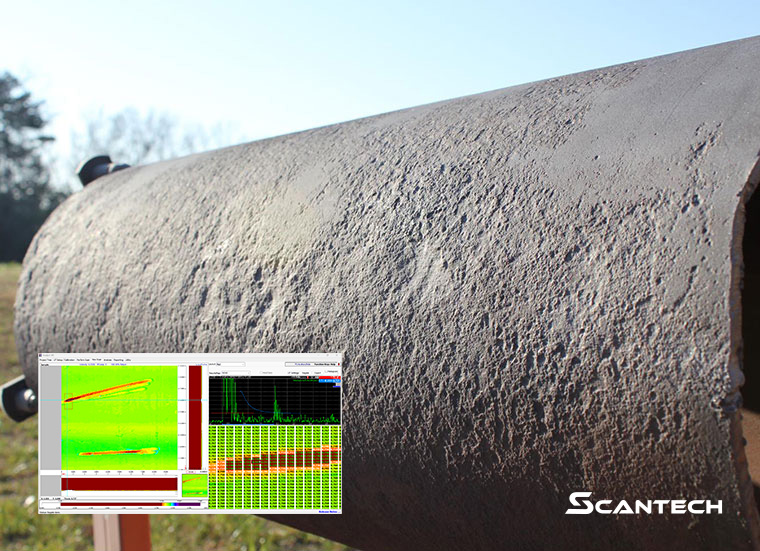

Corrosion mapping is crucial for industries that depend on the longevity and integrity of their assets. Corrosion in oil pipelines, storage tanks, and industrial infrastructure can lead to expensive downtime and hazardous leaks. In severe cases, it can even cause catastrophic failures. To avoid these risks, industries must monitor corrosion carefully.

Nondestructive Testing (NDT) is a key method for detecting, evaluating, and mapping corrosion without damaging assets. In this post, we’ll look at five essential tools for effective corrosion mapping in NDT. These tools range from manual scanners to advanced software solutions. We’ll also show how they make inspections faster, improve accuracy, and enhance safety.

1. XR Spider: Automated Corrosion Mapping with High Performance

For larger industrial assets like tanks, vessels, and pipelines, automated scanning is the way forward. The XR Spider is an industry-leading automated corrosion mapping system that excels in covering large surfaces quickly and accurately. This scanner is highly maneuverable and designed to overcome obstacles that would impede most tank crawlers. With its unique four-wheel drive and powerful torque, it can navigate challenging terrains and adhere to both curved and flat surfaces.

The XR Spider’s high scanning speed and real-time monitoring capabilities allow for rapid data acquisition. It can scan pipes as small as 2 inches in diameter without needing manual adjustments, making it incredibly versatile across applications. Additionally, its closed-loop servo control ensures precise movements, providing consistent data even in rugged environments.

2. X3 Spider: Ultrasonic Corrosion Inspection Made Easy

The X3 Spider excels at ultrasonic corrosion mapping, a highly portable and rugged solution for tanks, pipes and vessels. While similar to B-scanning, corrosion mapping is different, it’s more detailed area scanning, often associated with C-scanning. Built from 6061 aluminum and 303 stainless steel the X3 Spider can withstand harsh environments without sacrificing performance.

A key feature of the X3 Spider is its closed loop control system which ensures precise positioning throughout the scan. The direct drive gear set prevents slippage common in chain or belt drives, so you get better accuracy and less maintenance. With the ScanTech magnetic encoder you get consistent readings even on tough surfaces. With this combination of toughness and agility the X3 Spider is the perfect tool for operators who need reliable corrosion inspection tools.

3. H3 Scanner: Reliable Manual B-Scan Corrosion Mapping

For manual inspections, the H3 Scanner offers a compact and easy-to-use solution. This handheld scanner provides precise B-scan corrosion mapping, suitable for smaller or hard-to-access surfaces. It’s especially useful in industries where spot inspections are required or where automated equipment may be impractical. Designed to work with Analyst B-scan software, the H3 Scanner enables seamless data acquisition and reporting.

What sets the H3 Scanner apart is its couplant recirculation system and low-friction, floating probe shoe. These features reduce noise, increase signal clarity, and minimize wear on the device itself. Additionally, it can be configured with either single or dual-element probes, providing flexibility depending on the inspection requirements. Optional accessories like a telescoping pole make it possible to inspect areas that would otherwise be out of reach, extending the scanner’s usability across diverse inspection environments.

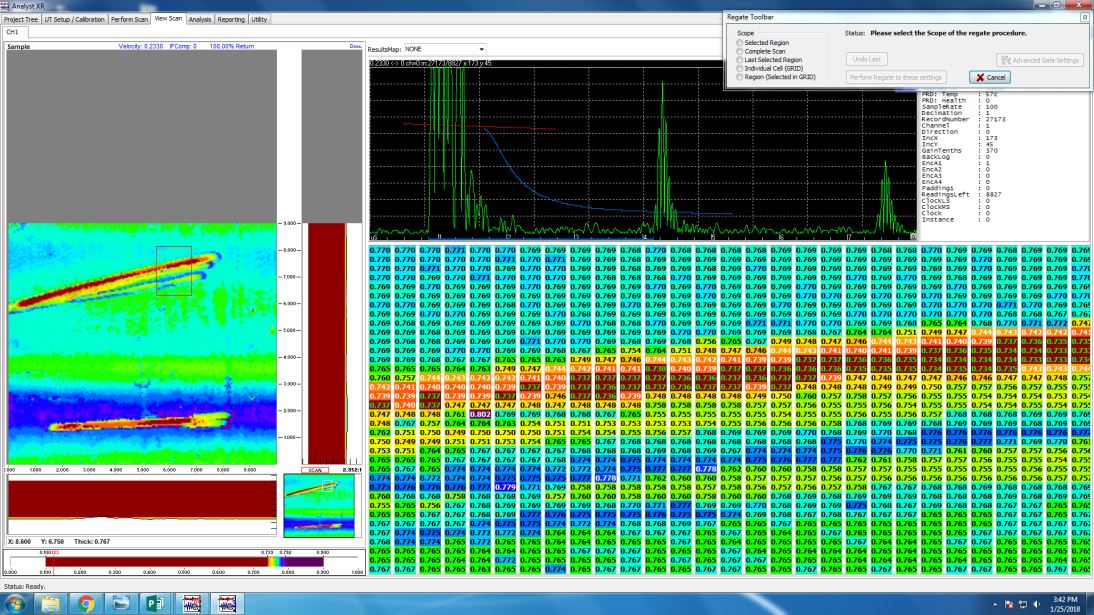

4. Analyst XR™ Software: Advanced C-Scan Corrosion Mapping and 3D Modeling

No corrosion mapping toolkit is complete without robust software. The Analyst XR™ software offers advanced C-scan corrosion mapping capabilities, which allow operators to collect and visualize data in new ways. It includes tools for creating a 3D model of scan data, which can be exported for further analysis or shared with clients. With the Analyst XR™, NDT technicians can not only map corrosion but also conduct B31G analysis to assess the integrity of pressurized pipes and vessels.

Analyst XR™ also includes features for re-gating, overlaying multiple scans, and creating customizable reports. The software’s interface is designed for easy navigation, allowing operators to adjust scan parameters as they work, enhancing data accuracy and reducing errors.

5. BPS System Power Pack: Essential Power for Field Inspections

The BPS System Power Pack is an indispensable tool for field inspectors working in remote locations with limited access to power. This rugged, portable power pack can keep NDT equipment running for over eight hours, ensuring uninterrupted inspections. It features a DC battery/AC adapter switch and audible low-battery warning, giving inspectors ample time to wrap up or replace the unit if needed.

Designed with a compact, vertical storage system, the BPS pack also provides safe storage for power supplies, chargers, and cords. This durability is matched by its simplicity of use, making it a must-have for technicians who frequently work in the field.