Ultrasonic testing (UT) is a core nondestructive testing (NDT) method used to detect material flaws, measure thickness, and ensure structural integrity across industries. As inspection demands grow — for speed, consistency, and comprehensive data — teams increasingly evaluate manual versus automated UT scanning approaches.

Each method has distinct implications on cost, accuracy, risk, and operational complexity. Understanding their differences helps procurement teams, inspection planners, and NDT technicians make aligned decisions that optimize inspection outcomes and justify investments internally. As ultrasonic testing in 2026 continues to evolve, understanding these tradeoffs helps inspection, operations, and procurement teams make aligned decisions.

Below is a structured comparison of manual and automated UT scanning, followed by guidance on when each approach makes the most sense — culminating in a practical checklist to support decision-making.

Head-to-Head Comparison

Comparing manual and automated UT involves understanding how each approach performs across several key inspection dimensions:

Setup Time

Manual UT is typically faster to set up. A technician can mobilize portable flaw detectors and hand-held transducers quickly to conduct targeted checks or spot inspections without building rigs or aligning mechanical guides.

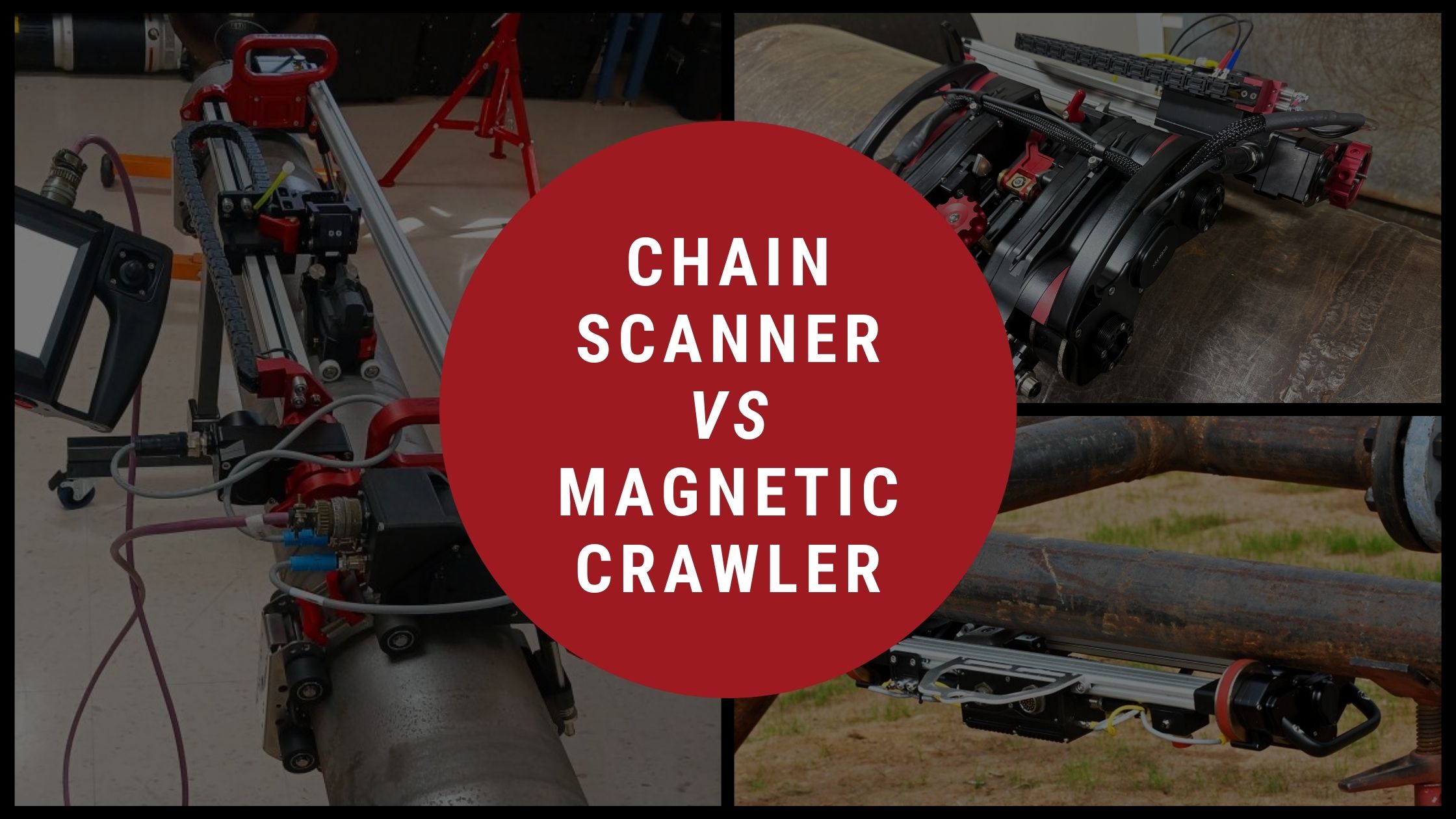

Automated UT setups often require a more deliberate preparation phase. Encoded, robotic, or crawler-mounted systems must be configured, positioned, and calibrated before data collection begins. Although setup time is longer, the volume of data collected once running can outweigh the initial effort — especially for large areas or repetitive tasks.

Repeatability

Repeatability describes how consistent data capture is from one pass to the next.

- Manual UT: Repeatability depends heavily on the operator. Different technicians may scan at slightly different speeds, orientations, or pressures — introducing variability that complicates comparison across scans.

- Automated UT: Mechanized motion control and encoded acquisition deliver consistent movement and data sampling patterns. This enhances repeatability, reducing noise from operator variability and improving confidence in comparative results.

Operator Dependency

Operator dependency affects both data quality and training requirements:

- Manual UT: Outcomes depend on the skill and discipline of the inspector. Experienced technicians can adapt to complex surfaces and nuanced inspection conditions, but variability persists between operators.

- Automated UT: Most motion and positioning functions are governed by programmed routines. While operators still need expertise to validate setups and interpret results, automated systems significantly reduce the influence of human variability on raw data quality.

Data Consistency

Consistent datasets are critical for trend analysis, defect tracking over time, and regulatory compliance reporting. Maintaining strong ultrasonic data quality best practices is easier when data capture follows a repeatable process.

- Manual UT: Data is typically captured in real time and must be recorded or logged manually. This often complicates later analysis or audit trails.

- Automated UT: Modern systems automatically record and archive data, creating structured datasets optimized for downstream review, comparison, and analytics — boosting traceability and repeatability in historical records.

When Manual Makes Sense

Manual UT remains the right choice in scenarios where flexibility, speed, and simplicity are priorities:

- Small inspections: Quick, spot checks or limited-area tasks where the overhead of automation isn’t justified.

- Complex geometries: Tight spaces or irregular shapes where mechanized tools may not reach efficiently without custom fixturing.

- Budget constraints: Lower upfront investment and minimal equipment complexity make manual UT practical for organizations with limited capital expenditure.

- Operator expertise matters: Where seasoned technicians’ judgment adds value to contextual decisions or unique test conditions.

When Automation Pays Off

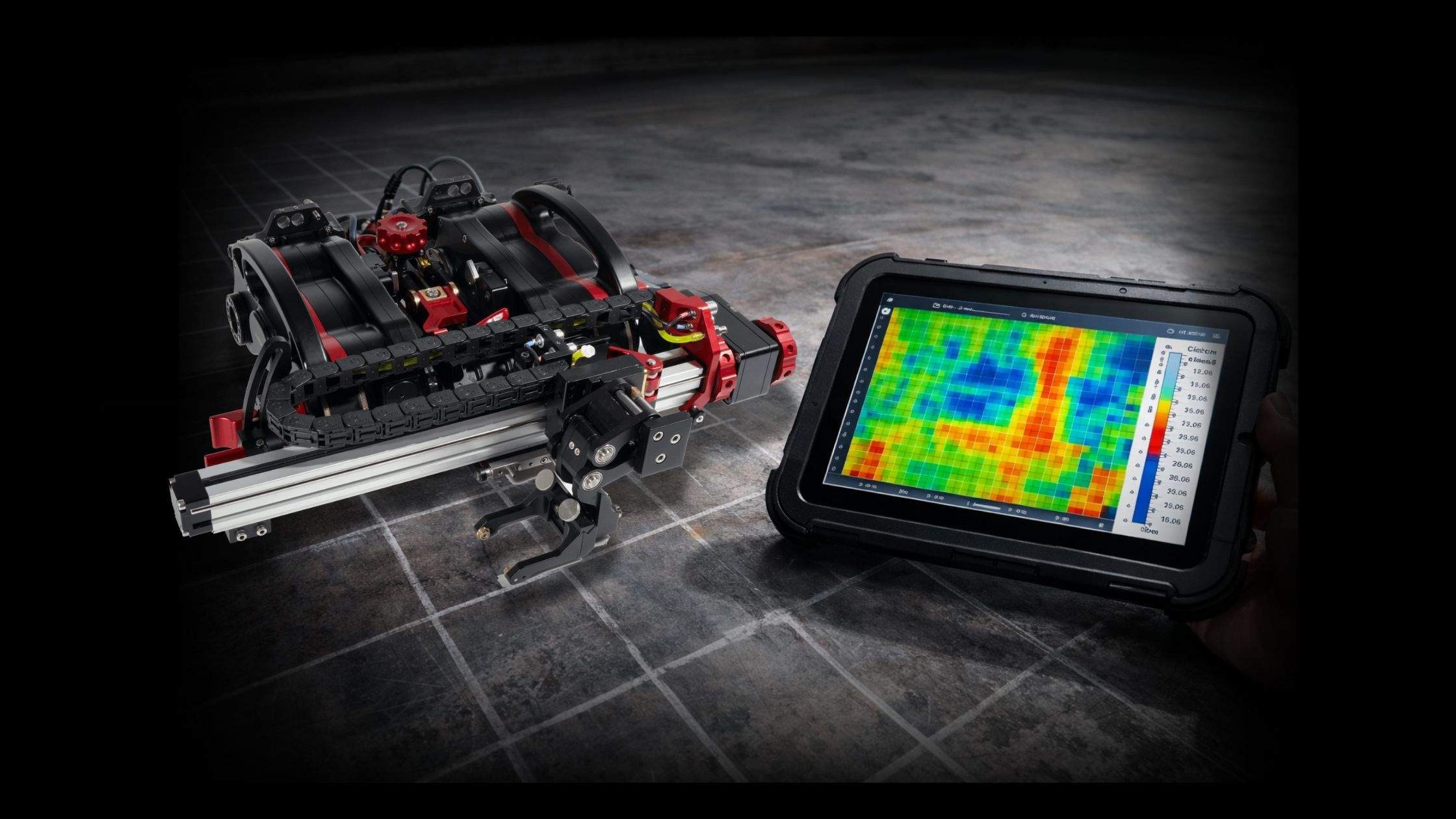

Automated ultrasonic scanning systems excels where volume, repeatability, and consistent documentation are essential:

- Large-area inspections: Corrosion mapping over tanks, pipelines, or vessel walls benefit from consistent, high-density data capture.

- Programmatic inspection regimes: Routine maintenance cycles or risk-based inspection programs where trend comparison is critical.

- Regulatory compliance: Environments that require demonstrable repeatability and robust audit trails.

- Risk reduction: Automated systems mitigate fatigue and inconsistency, lowering the risk of missed indications and rework.

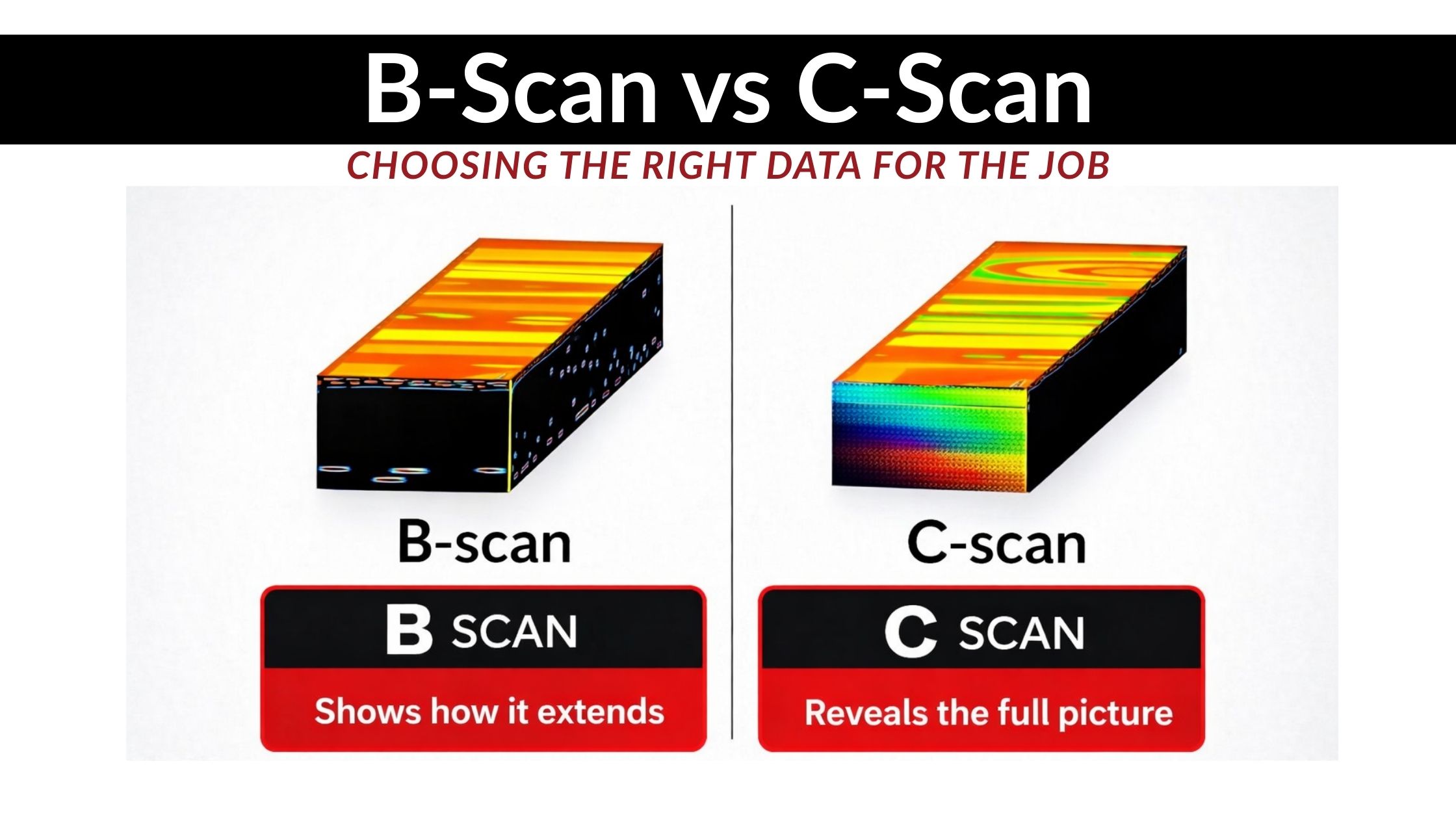

Even within automated methods, there are hybrid approaches that merge manual adaptability with encoded scanning precision, offering a middle ground for workflows that need both flexibility and data structure. Understanding B-scan vs C-scan ultrasonic data formats helps teams choose workflows that match inspection goals.

Checklist for Selection

Use this checklist to guide decision points when choosing between manual and automated UT scanning:

Inspection Scope & Scale:

☐ Is the inspection area large or repetitive?

☐ Will multiple scans be compared over time?

Data Quality Requirements:

☐ Is high repeatability and archival traceability needed?

☐ Are structured datasets required for compliance reporting?

Geometry & Accessibility:

☐ Does the asset surface have complex shapes or limited access?

☐ Would mechanized systems struggle without custom fixtures?

Budget & ROI:

☐ Is there capital budget available for automated systems?

☐ Will the automation investment save operational costs over time?

Operator Skill & Resources:

☐ Do inspectors have expertise with advanced tools?

☐ Is training capacity available for new technologies?

Scoring these factors helps teams categorize their needs and identify which scanning approach aligns best with technical requirements and business goals.

Next Steps for Your Inspection Strategy

Choosing between manual and automated UT scanning isn’t just a technical choice — it’s a strategic one. If you’d like help evaluating which option best fits your workflow, asset profile, and inspection goals:

Request a demo of ScanTech’s ultrasonic scanning solutions or Contact our technical team for a tailored consultation.