UT’s Evolving Role in 2026

Ultrasonic Testing in 2026 continues to play a critical role in asset integrity, safety, and inspection reliability across industries such as oil and gas, power generation, and manufacturing.

New digital workflows and automated scanning technologies are reshaping how inspections are performed. At the same time, the fundamentals of ultrasonic testing (UT) remain essential for producing accurate, decision-grade data.

As the industry moves into 2026, UT continues to evolve. Advances in digital workflows, data processing, automation, and analytics are changing how inspections are planned, executed, and interpreted.

Despite these advancements, several core principles still matter. Proper surface contact, disciplined calibration, and consistent data quality remain central to reliable inspection results.

This article outlines what has changed, what has not, and why strong UT fundamentals still define inspection success.

What Has Changed in Ultrasonic Testing in 2026

1. Digital Workflows and Real-Time Visualization

One of the biggest shifts in recent years is the move away from standalone instruments. Ultrasonic equipment is now commonly integrated into broader digital inspection workflows.

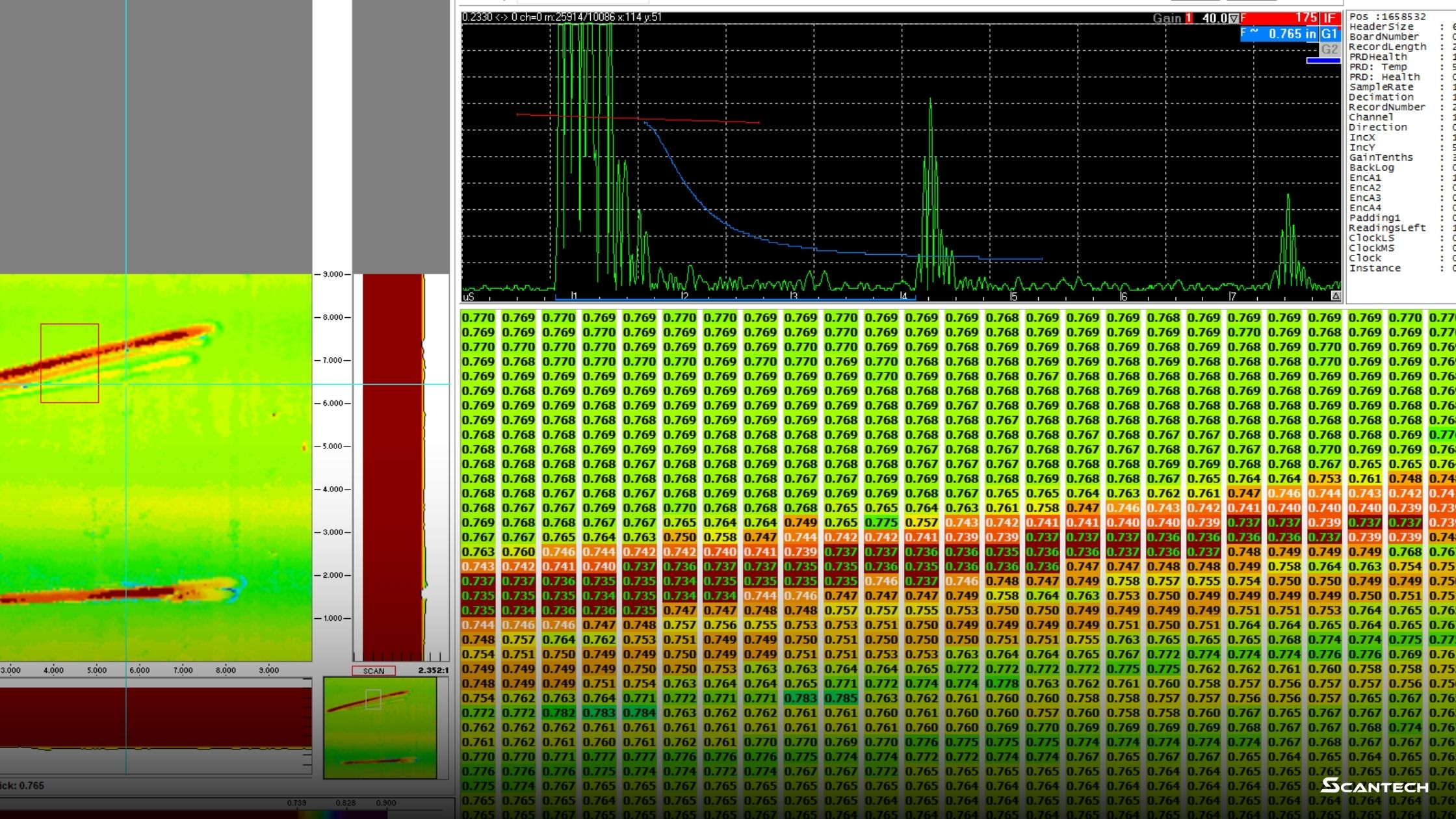

Today’s UT systems capture decision-grade datasets that can be reviewed, audited, and compared over time. This marks a shift from earlier workflows where interpretation happened almost exclusively in real time on site.

Richer data capture—such as C-scan maps, saved setups, and structured scan records—improves traceability and long-term inspection value. These datasets also support better lifecycle management of critical assets.

Digital workflows improve collaboration across teams. Field technicians, engineers, and managers can review the same data, reducing misinterpretation and improving confidence in inspection outcomes.

Understanding B-scan vs C-scan ultrasonic data formats is now a key part of building effective digital inspection workflows.

For inspection teams evaluating how data is captured and interpreted, understanding B-scan vs C-scan ultrasonic data formats is now a critical part of building an effective digital workflow.

2. Automated Scanning Adoption

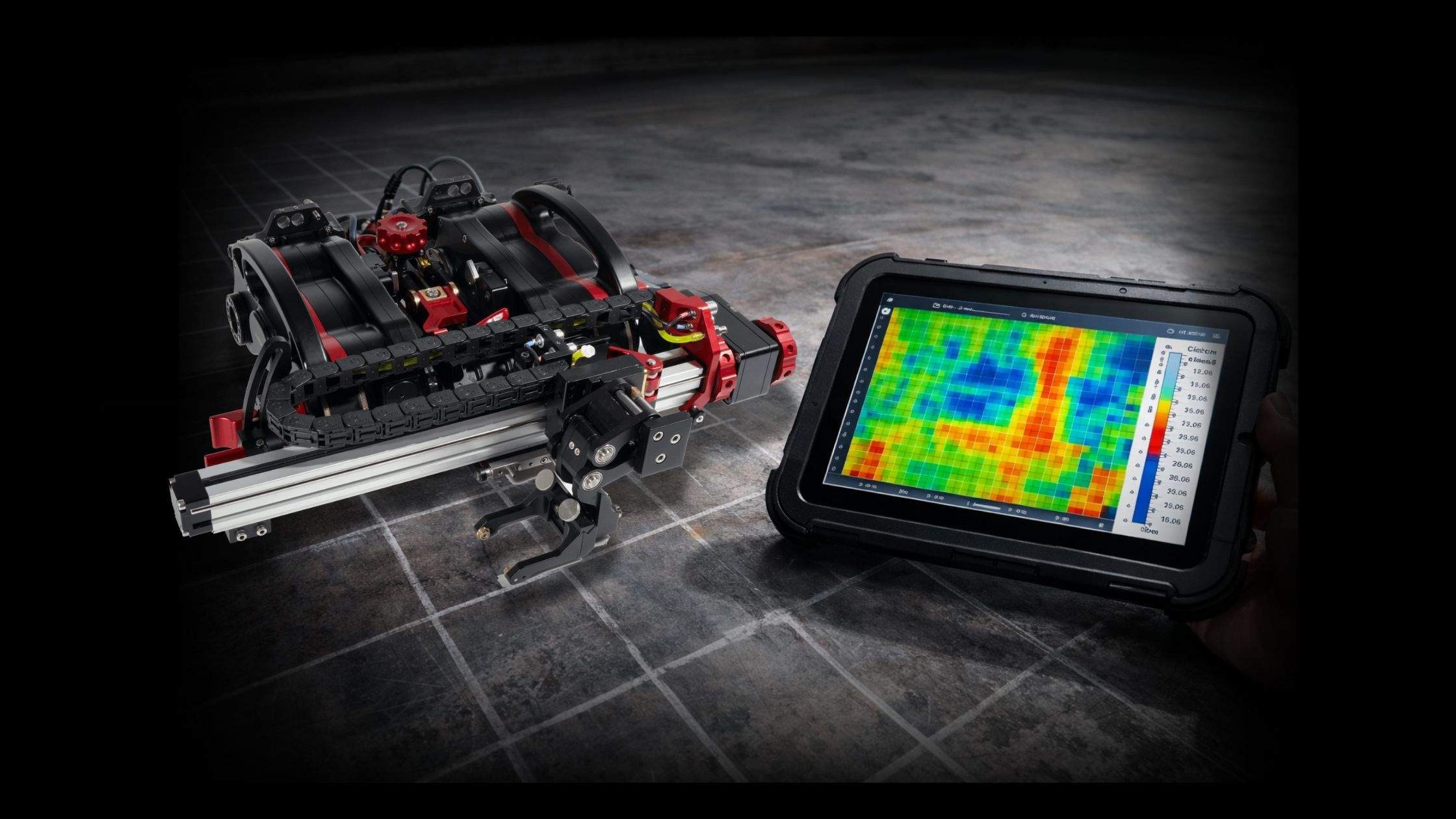

Automation continues to gain traction as teams seek more consistent inspection results. Automated ultrasonic scanning systems reduce human variability and improve repeatability by controlling movement patterns, encoding positioning, and capturing uniform datasets across similar inspection tasks.

Automated UT technologies—including robotic buggies, mechanical scanning rigs, and guided frameworks—have become common where inspection volumes are large or repetitive. These systems free technicians to focus on interpretation and decision-making rather than manual scanning mechanics.

In applications such as pipeline weld inspection or pressure vessel scrutiny, automation accelerates workflows and enables teams to reduce inspection time while maintaining high standards of data consistency. Many organizations now evaluate manual vs automated UT scanning as part of broader equipment investment decisions.

3. Data Reporting and Analytics

Inspection data is no longer just a snapshot—it is actionable insight. Modern UT platforms incorporate advanced reporting modules and analytics engines that transform raw data into decision support. Real-time visualization tools flag anomalies, trend defect growth, and support maintenance planning and compliance reporting.

As data volume increases, maintaining strong ultrasonic data quality best practices becomes even more critical. Without disciplined workflows, advanced analytics cannot compensate for poor underlying data.

These capabilities enhance operational confidence and align inspection results more directly with business, safety, and regulatory outcomes.

What Hasn’t Changed in Ultrasonic Testing

Despite technological progress, several foundational principles of ultrasonic testing remain critical.

1. Need for Proper Surface Contact

Regardless of automation or digital sophistication, efficient transmission of ultrasonic energy from probe to test material remains the first critical step. Proper surface preparation and consistent coupling reduce air gaps and facilitate effective wave propagation. Without good contact, signal strength weakens and reflects unpredictably, compromising defect detection and measurement accuracy.

This requirement has not changed since the earliest UT applications and remains a core competency for inspectors in the field.

2. Calibration Discipline

Accurate UT results still depend on proper calibration. Equipment must be calibrated for material type, thickness, geometry, and inspection method. Calibration standards ensure that response times and amplitudes correlate correctly with known reference benchmarks.

While modern systems offer guided calibration workflows and automated checks, disciplined calibration practices—such as verifying probe performance and using validated reference blocks—remain essential for defensible inspection results.

3. Data Quality Fundamentals

Technology may advance, but data quality fundamentals do not. Reliable inspection outcomes depend on repeatable setups, controlled motion, noise minimization, and consistent test parameters. Whether data is collected manually or through automation, poor data quality increases ambiguity, re-inspection rates, and operational risk.

Real-world UT inspections still rely on experienced technicians who understand how to interpret signals, identify anomalies, and validate results—skills that remain as relevant in 2026 as they were decades ago.

The Bottom Line: Integrating Tools with Operator Expertise

In 2026, ultrasonic testing sits at the intersection of advanced technology and proven fundamentals. Digital workflows, automation, and analytics provide inspection teams with richer datasets and improved efficiency—but these tools only deliver value when built on disciplined technique and strong UT fundamentals.

Integrating modern inspection technology with operator expertise ensures UT results are not just data points, but actionable insights that support confidence, compliance, and sound operational decisions.