Table of Contents

Facing the Real Cost of Unseen Corrosion

You know the drill: a few spot checks suggest things are fine—until things aren’t. Missed corrosion or thinning pipes can lead to catastrophic failures, downtime, and hefty repair bills. That’s why selecting the right inspection method—whether Guided Wave Ultrasonics (GWU) or Corrosion Mapping (C‑Scan)—matters. Let’s walk through the differences, trade-offs, and why using both in tandem could be the best move.

What Is Guided Wave Ultrasonics (GWU)?

GWU sends low-frequency ultrasonic waves along a pipe’s wall—sometimes from one access point—and picks up reflections from defects, welds, or supports. It can screen hundreds of meters in minutes. The magic? You get rapid, long-range coverage without removing insulation.

ScienceDirect researchers note it excels at locating anomalies but isn’t precise enough to size them—think of it as a high-level radar scan.

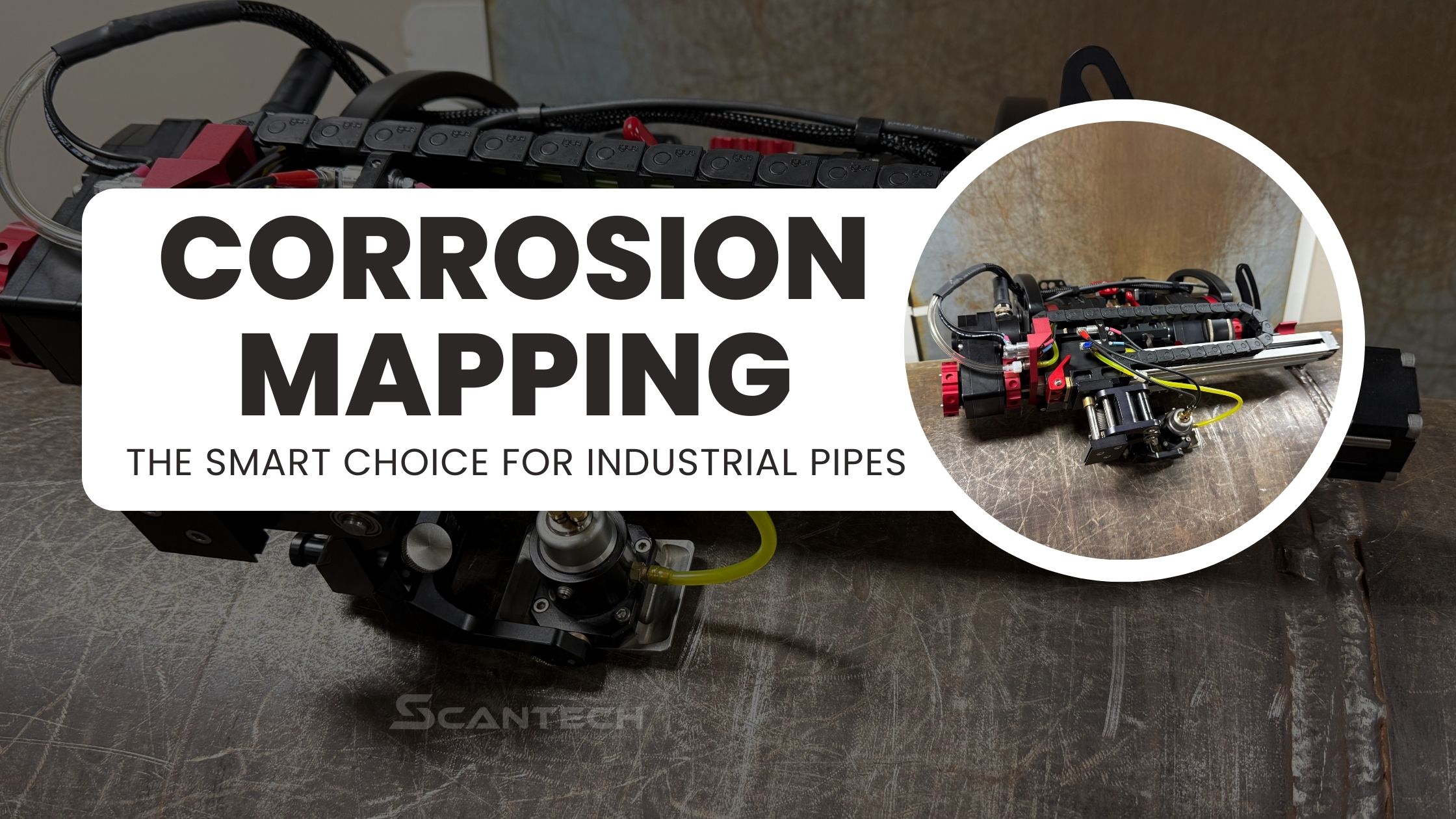

What Is Corrosion Mapping (C-Scan)?

Switching to corrosion mapping, you dive in with a grid-like ultrasonic scan, capturing high-resolution thickness data of the pipe’s surface. The result? A color-coded map—think thermal imaging but for wall loss—that shows exactly where corrosion has eaten away at metal.

This method is precise. When planning repairs or managing asset integrity, you need this level of clarity. Below is an example from a field inspection, showing the defect as seen on the surface, in a corrosion map, and in a cross-section profile:

What Is the Process of Corrosion Mapping?

You and your team will:

- Prep the surface—strip paint and dirt for clean coupling.

- Apply couplant—gel or water ensures acoustic contact.

- Calibrate scanner based on pipe parameters.

- Run the scan—often motorized for speed and accuracy.

- Analyze results—C‑scan maps with built-in algorithms to flag damage.

What Is a Guided Wave Analysis?

When you run a GWU test, you’ll see spikes on a trace—each spike signals a change in the pipe. These might tell you there’s corrosion or a weld fifty meters out—but not how deep it is. That’s where follow-up NDT like corrosion mapping comes in.

Guided Wave vs. Bulk Wave — What’s the Difference?

| Feature | Guided Wave (GWU) | Bulk Wave (Corrosion Mapping) |

| Range | Long (tens to hundreds of meters) | Short (inches to feet) |

| Frequency | Low (10 kHz–several 100 kHz) | Higher (MHz range) |

| Resolution | Lower | High |

| Purpose | Screening | Precise sizing and mapping |

| Setup | Quick, minimal prep | Requires prep and access |

The Difference Between Guided Wave and Corrosion Mapping

In plain terms: GWU is great for saying “Hey, something’s off down there.” Corrosion mapping says, “Here’s exactly what, where, and how bad.” One flags potential problems fast. The other gives you the detailed data to act confidently.

When to Use GWU vs. Corrosion Mapping

- GWU: When you’re short on access or time—like buried or insulated pipelines.

- Corrosion Mapping: For high-stakes areas like welds, tank shells, or segments flagged by GWU.

- Smart Combo: GWU for screening large areas; corrosion mapping for focused detail work. Efficiency and accuracy achieved together.

What Are the Different Types of Guided Waves?

- Torsional (T) mode: resistant to coating and good for long-range.

- Longitudinal (L) mode: deeper penetration, versatile.

- Flexural (F) modes: more complex; variable sensitivity.

Advantages and Limitations of Each Method

How Does a Wave Guide Work?

How Does a Wave Guide Work?

Here’s the science in plain English: the pipe wall acts like a highway for guided waves. They “hug” the pipe and ride its surface, bouncing back from any defect. That’s what gives GWU its range—but also its limited detail.

Frequency of Guided Waves and Its Impact

Lower frequencies travel further but give fuzzier reflections. Higher frequencies sharpen up detail but don’t go as far. It’s a classic engineering trade-off.

Real-World Case Studies

- Offshore risers: TWI used GWU to screen under insulation and detect corrosion before mapping critical areas.

- Corrosion under supports (CUPS): Eddyfi combined GWU for detection and mapping for sizing.

- Onshore rehab: Pipeline surveyed using GWU, then repairs planned using C-scan data.

Build an Inspection Strategy That Works for You

There’s no single silver bullet—GWU and corrosion mapping serve complementary roles. Start with GWU for fast screening. When alarms go off, bring in corrosion mapping for precision. That way, you’re surveying smart and acting strategically.

Let’s make your inspections smarter, faster, and more reliable.

Ready to optimize your inspection process? Explore our guided wave and corrosion mapping solutions and see how combining both accelerates decision-making and minimizes risk.

FAQs

A: Guided Wave Analysis involves launching low-frequency ultrasonic waves along a pipe and capturing reflected echoes. You’ll interpret the signal pattern—like amplitude and time-of-flight—to locate anomalies such as corrosion or weld defects. It’s a high-speed screening approach that flags where detailed inspection should focus.

A: Guided wave testing typically operates in the 20–200 kHz range, depending on the pipe’s characteristics. Lower frequencies travel farther but offer less resolution; higher ones pinpoint smaller defects but don’t go as far.

A: There are three main wave types: Torsional (T), Longitudinal (L), and Flexural (F) modes. Torsional is commonly used for its simplicity and uniform propagation. Longitudinal and Flexural can offer enhanced sensitivity in specialized scenarios.

A: Corrosion mapping operates in these steps:

- Surface prep (strip coatings/back-out loose scale)

- Apply couplant (water or gel)

- Calibrate scanner (for pipe size/material)

- Sweep with motorized or manual grid

Analyze data with software to generate a color-coded thickness map

This method delivers high-resolution visual data for precise assessments.

A: Use Guided Wave Ultrasonics (GWU) for fast, long-range condition screening—especially useful for inaccessible or insulated piping. When you need precise defect sizing or must comply with API/ASME standards, switch to Corrosion Mapping (C-Scan). A hybrid of both maximizes efficiency and accuracy.