Home » Products » NDT Software » Analyst X™ Software for B-Scanning

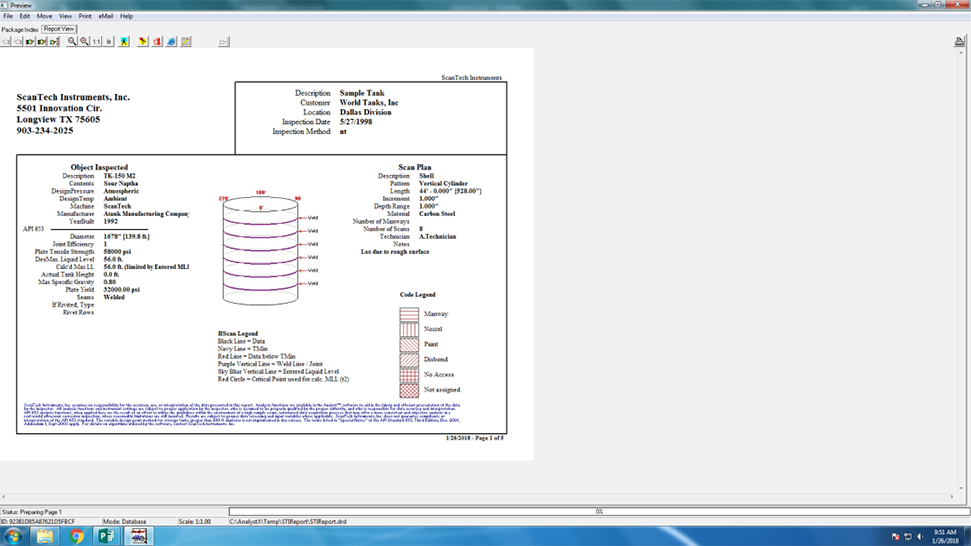

Generating reports is fast and easy with Analyst X™. Automated reporting includes scan plan information and B-Scans associated with the vessel. Create B-Scan overlays for comparison and print charts showing the high, average, and low thickness values of each scan. Data tables and C-Scan views can also be printed for comprehensive reporting.

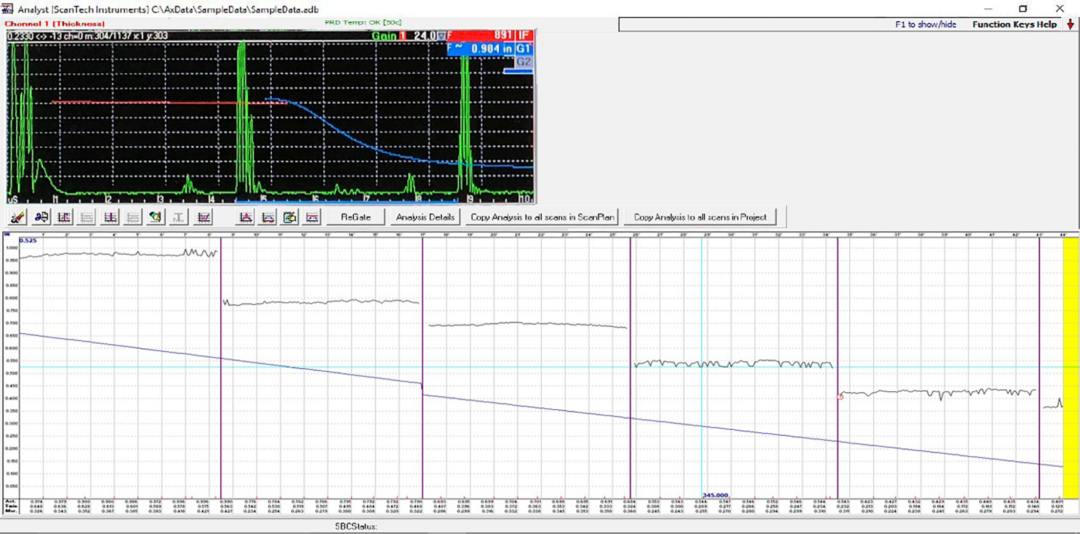

The re-gating function allows users to clean up data by re-gating selected regions or entire scans to reduce noise interference. Gates are easy to manipulate, adjusted simply by clicking and dragging.

As the scanner maps corrosion, data appears on the screen in real-time. This allows for immediate monitoring and gain adjustments during the scan for optimal results.

Post-scan, users can add weld lines, flag values, re-gate data, and perform statistical analysis to get the most accurate and detailed results.

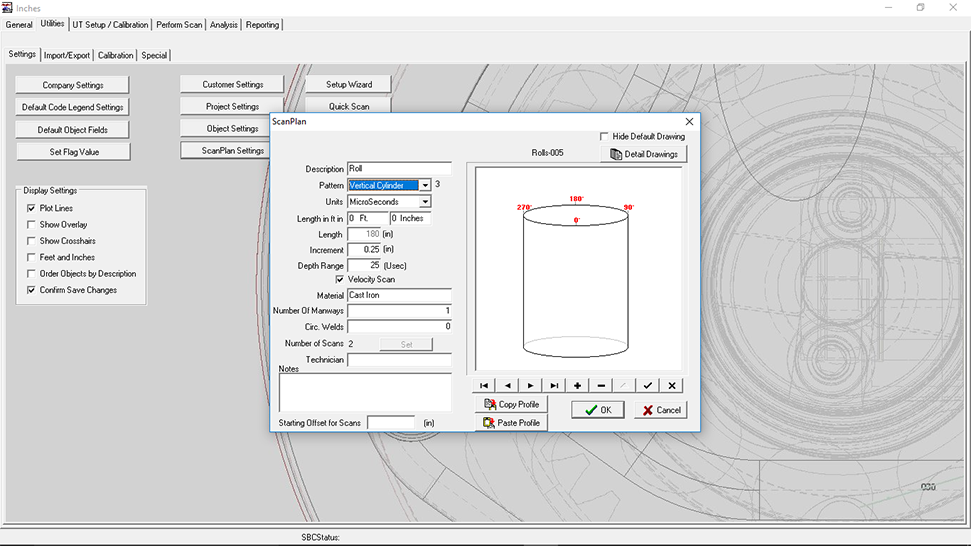

Analyst X™ is initially configured for use with the X2-X3 Spider System for tank inspections. For dryer roll inspections, the system can be enhanced by adding the D2S add-in to the Analyst X software. This upgrade transitions the system to a Dual-Channel Dryer Scanning System. Additional components, such as a second channel for the X Controller, D2S calibration blocks, D2S wedge, D2S jumper cables, and D2S main cable, are then integrated to complete the D2S system.

Schedule a meeting with our experts to explore how our advanced NDT solutions can benefit your operations.

ScanTech Instruments has been an invaluable partner to MFE Inspection Solutions for several years, providing cutting-edge ultrasonic testing scanners that consistently deliver precision and reliability in the most challenging environments. As a leader in non-destructive testing, ScanTech's dedication to innovation and quality aligns seamlessly with MFE's commitment to offering the best inspection solutions on the market. Under the leadership of Alan Dorsey, President of ScanTech, the company has reached new heights in the inspection industry. Alan's extensive background in inspection and his deep understanding of the industry's demands have been instrumental in shaping ScanTech's product offerings to meet the evolving needs of our clients. His commitment to excellence and his hands-on experience in the field ensure that every ScanTech product is engineered with the inspector in mind, providing unmatched reliability and efficiency.