Table of Contents

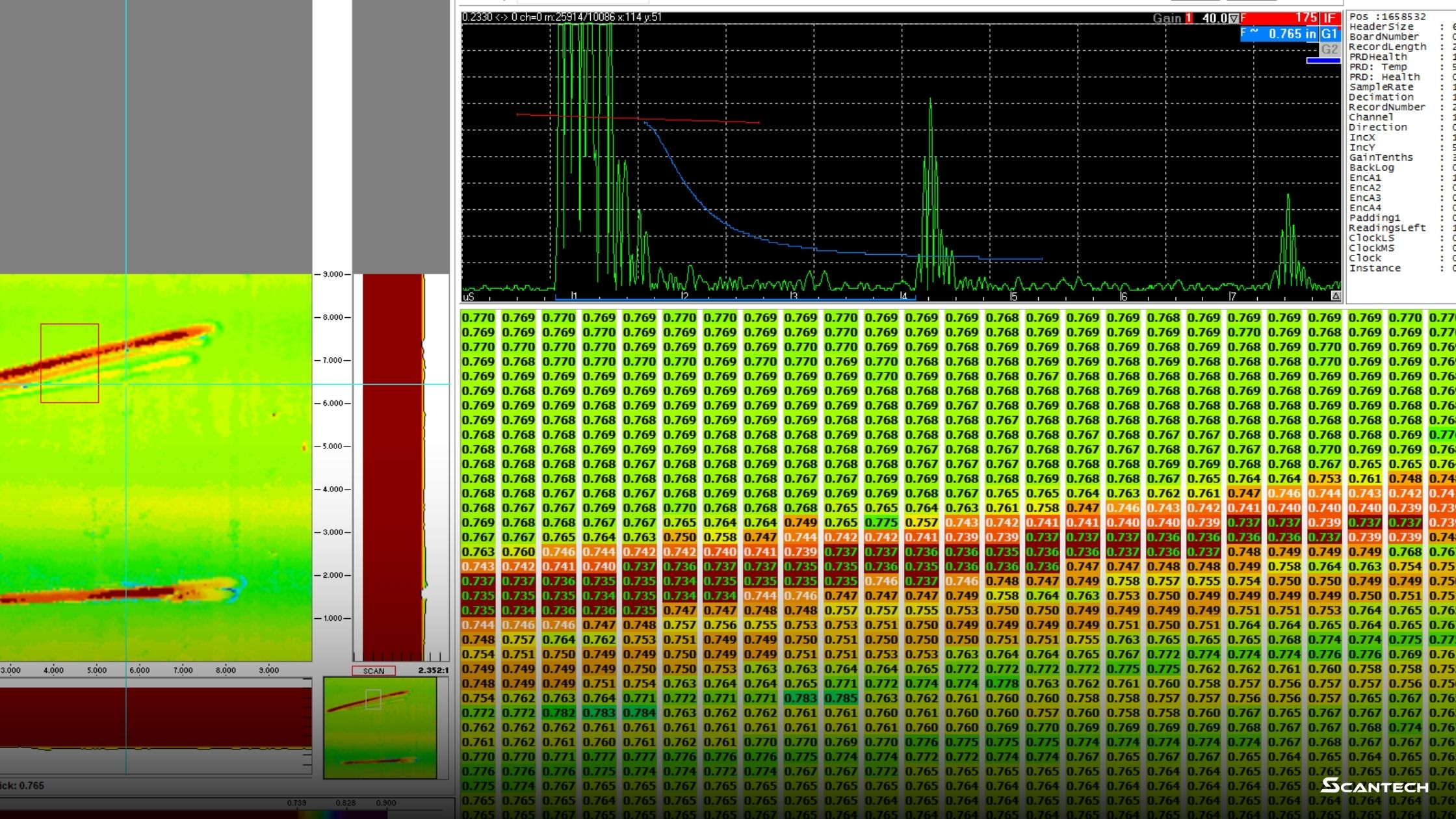

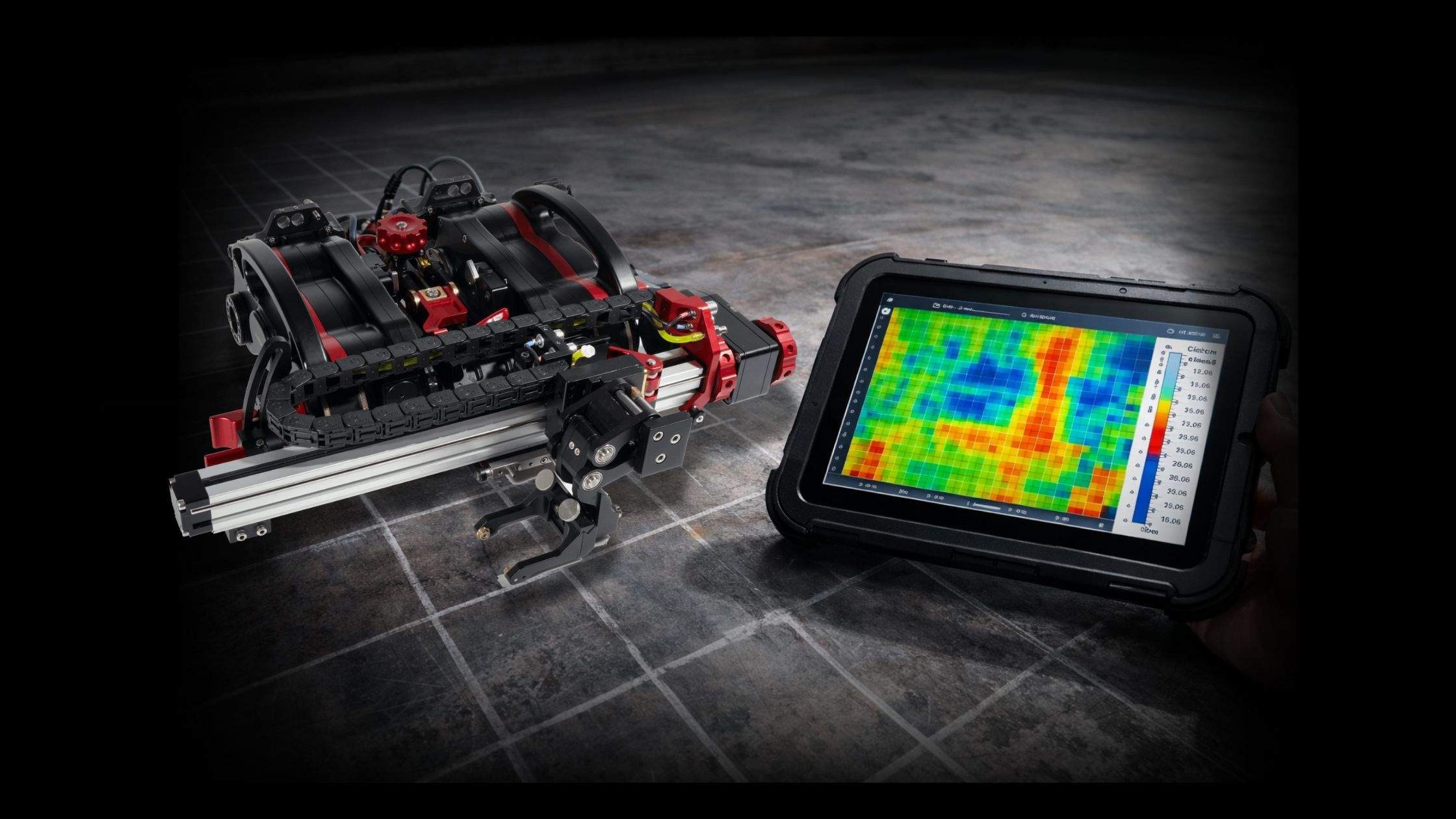

The XR Spider is an automated ultrasonic corrosion-mapping scanner engineered for high-resolution C-scan imaging on pipelines, vessels, and large-diameter tanks.

Built for rugged field deployment, it delivers consistent coupling, repeatable data, and faster coverage — now supported by a built-in scan-time and pass-count estimator for improved inspection planning and crew efficiency.

Real-World Inspection Challenges

Inspecting large-diameter piping and storage tanks is labor-intensive and time-sensitive. Manual scanning introduces uneven coverage, variable coupling, and operator fatigue — all of which lead to inconsistent wall-thickness data.

When schedules tighten, every re-scan adds cost, delays, and uncertainty.

- For Level II technicians: Setup time and scanner reliability directly affect turnaround success.

- For Level III managers: Data density and repeatability determine inspection credibility and code compliance.

- For inspection-service owners: Fewer re-scans and reduced rental dependence translate into stronger ROI and uptime.

How the XR Spider Solves It

Designed and manufactured in Texas, the XR Spider is a fully automated raster scanner purpose-built for corrosion-mapping applications.

Its drive system and probe carriage maintain constant coupling pressure and orientation across curved surfaces — eliminating the need for manual adjustment.

The XR Spider in Action

The scanner performs circumferential and longitudinal passes on assets ranging from 2-inch pipe OD to large-diameter vessels, maintaining accurate position encoding throughout every scan.

Key Features

-

- Automated Raster Motion – Provides uniform, encoded motion for precision C-scan corrosion mapping.

- Self-Aligning Probe Assembly – Maintains perpendicular coupling on curved geometries for consistent amplitude and signal quality.

- Touchscreen Control Interface – Integrated display enables precise control and live monitoring during automated passes.

- Rugged Construction – Machined from 6061-T6 aluminum and 303 stainless steel with sealed encoders for durability in harsh environments.

- Constant-Force Spring Mechanism – Applies uniform probe pressure across all radii without adjustment.

- System Integration – Seamlessly compatible with Analyst XR C-Scan Software and the Batt Pack Pro Controller for complete automation and real-time data acquisition.

Together, these design elements eliminate slippage, uneven pressure, and data drift commonly found in belt- or chain-driven scanners.

Field-Ready Design for Every Role

For Technicians

Fast setup, no tool changes, and reliable coupling — even on vertical or overhead surfaces. Joystick or touch-screen control provides smooth, responsive motion for automated scanning.

For Maintenance Managers / Level III Inspectors

Delivers high-resolution, repeatable C-scan data with full compliance confidence for API 653 and ASME B31G standards.

For Service Company Owners

Minimizes project downtime and rental dependency, reducing cost per inspection and maximizing uptime across crews and sites.

Explore More

Plan Your Inspection Time

Use the interactive tool below to estimate total scan time and pass count for your tank or pipeline based on length, pass width, and resolution settings.

This helps inspection teams plan coverage and crew allocation before mobilizing to the field.

(The calculator is designed for any NDT scanning configuration, not just the XR Spider.)