Table of Contents

In the oil and gas industry, failures are not an option. Every pipeline, tank, and weld must perform under extreme conditions. Ultrasonic Testing (UT) is a cornerstone of asset integrity programs — it detects thinning, flaws, and defects before they become disasters. In this post, we dive deep into how UT is used in oil & gas, the field challenges, and proven best practices.

Pipeline Inspection

Pipelines form the backbone of oil & gas infrastructure. UT helps operators spot trouble before it becomes costly.

- UT measures wall thickness along pipe segments to find corrosion or erosion.

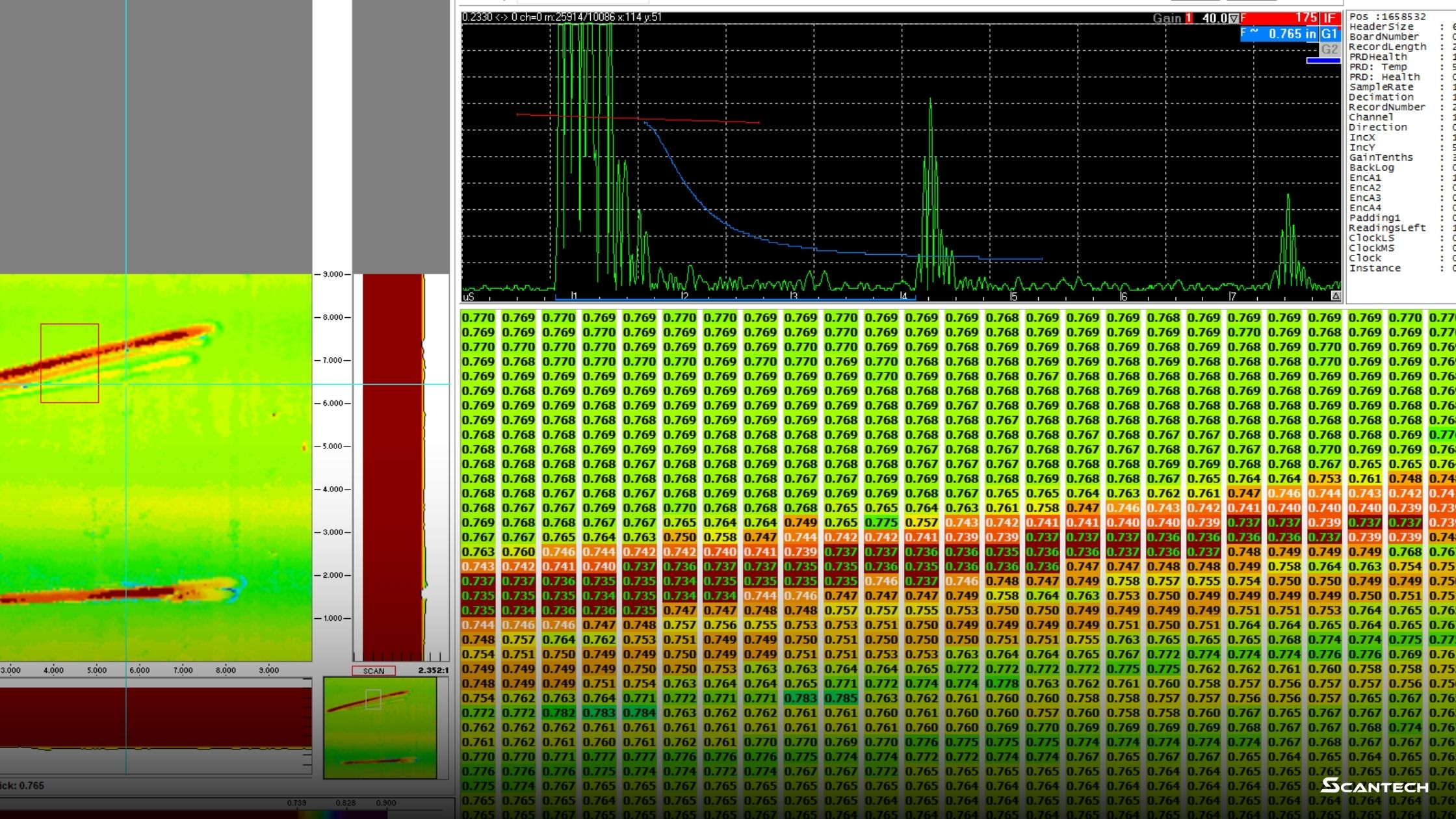

- Using phased array or raster scans, inspectors map thickness across the pipeline to visualize “hot spots.”

- UT inspects welded joints (girth welds, butt welds) for cracking, lack of fusion, porosity, and inclusions.

- For long lengths of pipe, guided wave UT can pre-screen segments, directing more detailed UT inspections where needed.

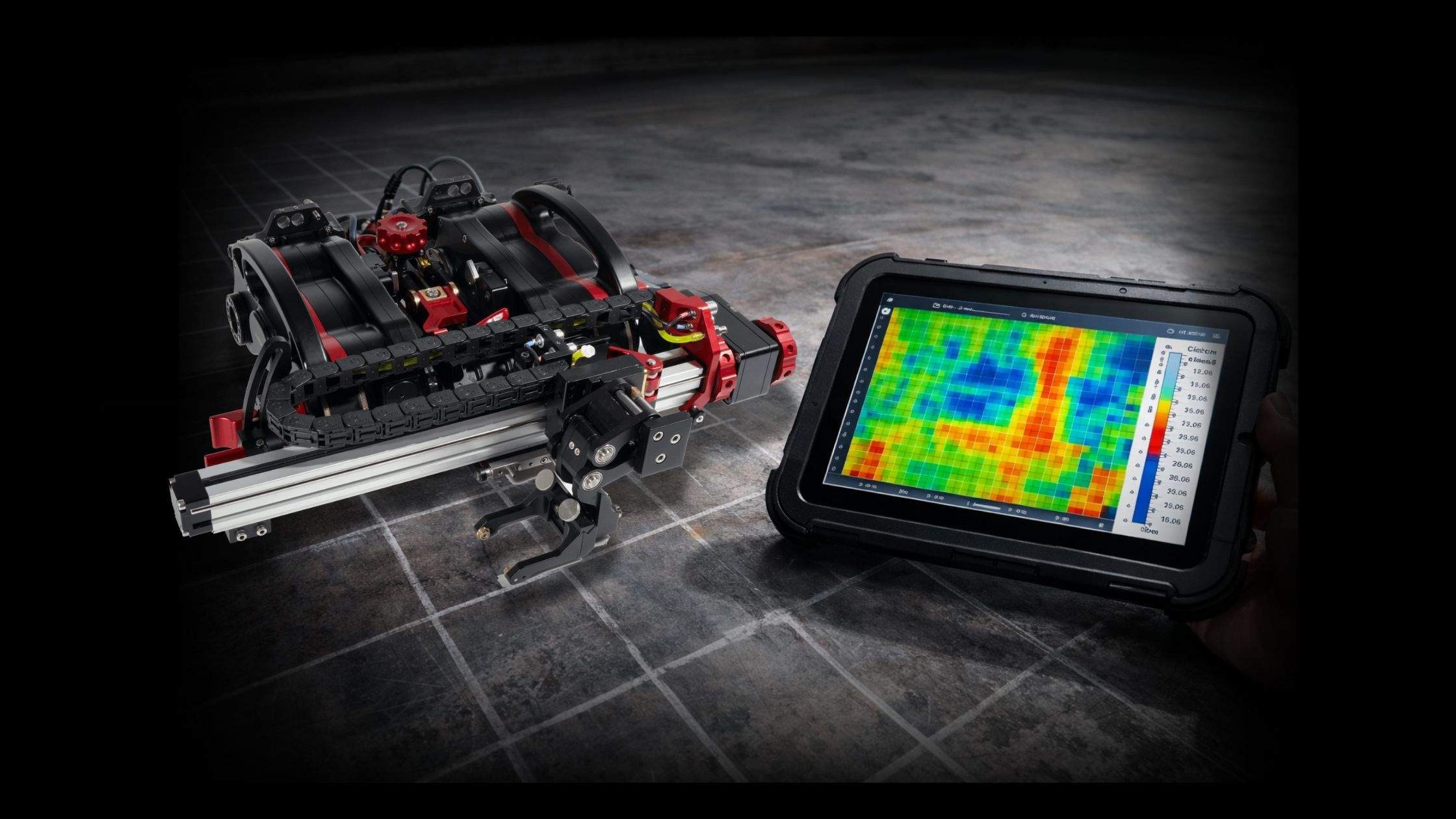

- In constrained or unpiggable lines, robotic UT crawlers traverse and inspect welds and pipe walls.

Corrosion Monitoring & Thinning

Corrosion is the enemy of longevity in oil & gas. UT is essential for measuring and trending wall loss.

- API 653 requires UT thickness testing for aboveground storage tanks. UT allows operators to calculate corrosion rates by comparing current thickness to baseline data.

- UT maps provide visual corrosion maps showing variation and possible pitting zones.

- Inspectors use UT on tank bottoms, shell walls, nozzles, and internal structural elements.

- Repeated UT over time helps schedule preventative maintenance or replacements before failures.

Weld Inspection

Weld zones are high-risk areas. Defects in welds can lead to leaks and catastrophic failures.

- Phased Array UT (PAUT) is commonly used because it offers angled beam steering, which covers heat-affected zones and multiple defect orientations.

- Angle-beam UT remains valuable for simpler weld configurations.

- UT can detect lack-of-fusion, cracks, slag, porosity, and undercuts in and around welds.

Challenges: Field Conditions & Accuracy

Real-world field oil & gas environments throw many curveballs to UT.

- Surface condition & coupling — rust, scale, coatings, or rough surfaces degrade signal. Preparation or use of delay lines may be required.

- Tight access & geometric constraints — pipes in bundles, insulation, or cladding can obstruct probe placement.

- Deposits / internal scale — scaling or deposit layers distort readings.

- Temperature effects & gradients — high temperatures and thermal gradients affect sound velocity and add noise.

- Complex weld profiles — overlapping welds, reinforcement, or variable shapes complicate beam paths.

- Calibration drift & probe wear — probes degrade, calibration must be checked frequently in the field.

- Operator skill & interpretation — multi-echo signals, complex geometries, and borderline signals require experienced interpretation.

Best Practices & Case Study

Best practices make the difference between superficial readings and actionable data.

- Start with baseline scans (as-built data) to compare later.

- Use overlapping grid scans with phased array mapping to reduce blind zones.

- Validate suspicious findings by switching angles or using auxiliary methods (e.g. radiography).

- Apply temperature compensation and re-calibrate probes in situ.

- Store UT data in a structured database for trend analysis.

- Use risk-based inspection to focus on critical zones rather than blanket scanning.

FAQ

What is the typical probe used in pipelines?

Straight-beam (zero-degree) or angle-beam probes are common for thickness and weld checks. For mapping, phased array probes help cover more area.

How often should inspections be done?

In storage tanks under API 653, UT is often carried out every 5 years if corrosion rates aren’t well known. Pipelines use inspection frequency based on risk, corrosion rate, and regulatory or client requirements.

What is the minimum thickness UT can reliably measure?

With proper setup and probe selection, UT can measure down to around 1 mm or less. However, very thin sections may be limited by the “dead zone” of the probe.

Apply These UT Strategies Today

Ultrasonic Testing is indispensable in the oil & gas sector, especially for pipelines, storage tanks, and weld integrity. When properly implemented—with calibration discipline, environmental adaptation, and data-driven decision making—UT helps keep operations safe and reliable.