Table of Contents

Digital Radiography Overview

Digital radiography (DR) is an evolution of conventional radiographic testing that uses digital detectors—such as flat panel detectors or computed imaging plates—to directly capture x-ray images and convert them into electronic data (instead of using film).

Because DR does not require chemical development, images are available almost instantly, can be enhanced digitally, and are easier to store, share, and analyze.

In the world of weld inspection and industrial NDT, ISO 17636-2 defines practices and quality criteria for digital radiographic testing of fusion-welded joints. Meanwhile, ISO 17636-1 defines film-based radiographic techniques, which still matter as a comparative baseline.

Digital radiography can be subdivided into:

- Computed Radiography (CR) — using imaging plates (photostimulable phosphor plates) that are scanned to digitize the image

- Digital Radiography (DDR / DR with digital detectors) — uses flat or flexible panel detectors that convert x-ray photons directly into electronic signals

How DR Works (Technical Flow)

- X-ray / Gamma Source

A radiation source emits x-rays or gamma rays at controlled energy levels. - Detector / Imaging Device

- In CR, an imaging plate captures the exposure; then it’s scanned by a reader to convert latent image to digital.

- In DR, a flat panel detector (often with scintillator + photodiode array) captures and converts x-ray attenuation to an electronic image.

- In CR, an imaging plate captures the exposure; then it’s scanned by a reader to convert latent image to digital.

- Signal Processing

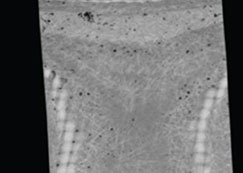

The raw digital image is processed by software (contrast/brightness adjustment, filtering, enhancement) to improve defect visibility. - Display & Analysis

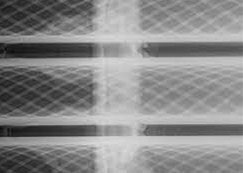

The image is displayed on a workstation; operators can zoom, pan, annotate, compare with standards, and archive. - Archiving & Sharing

Digital images can be stored, backed up, transmitted, or compared across sites with ease.

Because DR removes the need for film handling and darkrooms, the workflow is faster and safer, especially in field use.

Advantages of DR vs Film Radiography

| Advantage | Explanation | Supporting Source |

| Speed / Instant Imaging | DR provides immediate image preview—no waiting for film development. | OnestopNDT, Inspectioneering |

| Lower Radiation Dose | DR often requires less exposure to produce comparable image quality. | NDT blog, Vidisco |

| No Chemicals / Film Handling | Eliminates chemical processing, reducing consumables and environmental hazards. | Inspectioneering |

| Better Dynamic Range & Contrast | Digital detectors capture a broader range of brightness levels, making it easier to see both low and high attenuation areas. | OnestopNDT |

| Image Enhancement & Post-processing | Operators can zoom, adjust contrast, apply filters, overlay standards, etc. | NDT blog, OnestopNDT |

| Efficient Storage & Sharing | Digital images are easier to store, backup, and transmit, eliminating film archiving challenges. | OnestopNDT |

| Operational Efficiency & Field Use | DR systems are increasingly portable, enabling inspections in remote or confined settings. | NDT.net, OnestopNDT |

One case: moving from film to computed radiography in piping functions has cut inspection time by ~50 % and reduced lifecycle costs by about 25 %.

However, DR systems typically have a higher upfront cost (detectors, software, hardware) compared to film-based systems.

Challenges / Limitations & Considerations

While DR offers many benefits, it comes with trade-offs and constraints:

-

- Detector Cost & Durability

Flat panel detectors are expensive and sensitive. Dropping or mishandling them can damage panels.

- Detector Cost & Durability

-

- Spatial Resolution vs Film

In some applications, film can offer higher resolution or sharper grain under certain conditions.

- Spatial Resolution vs Film

-

- Dynamic Range Saturation / Overexposure

If exposure is too high, digital detectors may saturate and lose contrast detail.

- Dynamic Range Saturation / Overexposure

-

- Detector Size & Geometry Limitations

Detectors may not conform to tight or curved geometries (though CR plates are more flexible).

- Detector Size & Geometry Limitations

-

- Software & Calibration Needs

Proper calibration, correction algorithms, and software versioning are critical. Standards like ISO 17636-2 lay out guidance.

- Software & Calibration Needs

-

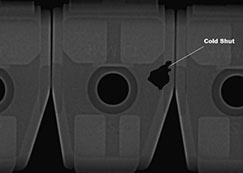

- Image Artifacts & Noise

Digital noise, scatter, beam hardening artifacts, and stitching artifacts can degrade interpretability if not managed.

- Image Artifacts & Noise

-

- Radiation Safety & Regulation

Even though DR may reduce total dose, radiation hazards remain. Regulatory compliance (shielding, licensing, safety zones) is mandatory.

- Radiation Safety & Regulation

-

- Legacy & Standards Mismatch

Older inspection programs or specifications may mandate film or reference prior film-based baselines, complicating adoption.

- Legacy & Standards Mismatch

Industrial Use Cases & Applications

DR is increasingly adopted across sectors where defect detection, speed, and data management matter.

Choosing DR vs UT (When to Use Which)

The decision between digital radiography and ultrasonic testing depends on many factors. Here’s a comparative look:

| Scenario / Requirement | Favor DR | Favor UT |

| Need full volumetric imaging of weld internals | ✅ DR | |

| Simple thickness or corrosion mapping | ✅ UT | |

| Complex geometry or limited line-of-sight | ✅ UT (especially phased array) | |

| Access constraints (field, confined) | ✅ portable DR if safe | ✅ UT often easier |

| Radiation safety constraints | ✅ UT (no ionizing radiation) | |

| Data storage, sharing & traceability | ✅ DR (digital) | UT may require data transfer systems |

| Cost consideration (capital vs consumables) | May be higher initial cost | Lower initial cost, but may need probes, calibration |

| Defect types (surface vs internal) | ✅ DR good for internal & volumetric | ✅ UT strong for subsurface, cracks, interfaces |

Find the Right Tool for Each Job

Digital radiography has transformed how we do volumetric inspections in NDT: faster results, richer image data, and easier data handling. But it’s not a universal solution—understanding its limits (cost, calibration, detector constraints) helps you choose the right tool for each job.

If you’re comparing UT vs DR for a specific use case (e.g. welds, pipeline, composites), drop me the details and I’ll help you pick and design the inspection method.