Table of Contents

Ultrasonic Testing (UT) is one of the most valuable techniques in nondestructive testing (NDT). It is known for its precision and reliability in detecting subsurface defects. As industrial structures like pipelines, storage tanks, and critical equipment age, they endure wear and tear. Ultrasonic testing provides a noninvasive way to assess their integrity. This ensures these assets remain safe and reliable, helping to prevent costly breakdowns and accidents.

How Does Ultrasonic Testing Work?

Ultrasonic testing in NDT uses high-frequency sound waves to detect flaws in materials. First, an ultrasonic transducer generates sound waves and sends them into the material. If there is a flaw or discontinuity, some of the sound waves reflect back to the transducer. This reflection, or echo, indicates the flaw’s location and size. UT works especially well for materials with complex shapes. It can penetrate deeply and provides precise, highly accurate measurements, even in challenging conditions.

Key Benefits of Ultrasonic Testing

Ultrasonic testing offers several benefits that make it a top choice across industries:

- Noninvasive: UT does not alter, damage, or affect the material being inspected. This makes it ideal for monitoring sensitive or high-value equipment.

- Accurate: UT can detect very small defects and measure thickness accurately. This level of precision is crucial for assessing corrosion or erosion in industrial components.

- Efficient: UT inspections are quick, requiring minimal equipment downtime. This makes UT ideal for environments where operational continuity is critical.

Advanced Ultrasonic Testing Tools

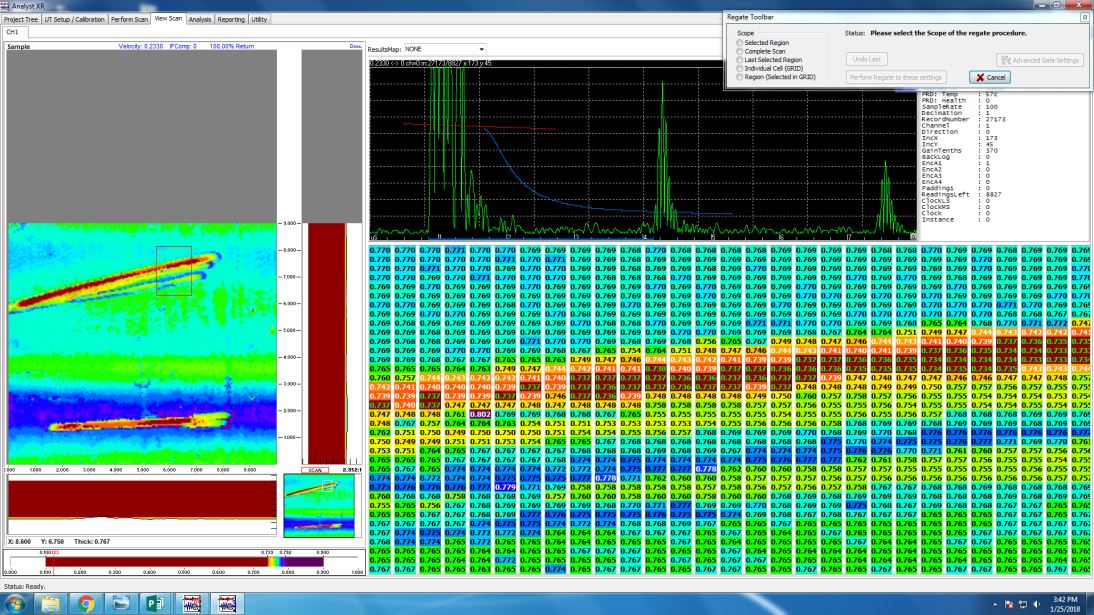

With advances in technology, ultrasonic testing has become even more efficient and reliable. Tools like the Analyst X™ software optimize data analysis through automated data acquisition, re-gating, and report generation. When paired with the X3 Scanner, Analyst X™ offers a compact, durable solution for ultrasonic B Scanning, making it ideal for challenging industrial environments. These advancements help technicians collect and analyze data faster and more accurately, leading to better decision-making and improved safety outcomes.

Ultrasonic Testing is a crucial tool in modern industry, combining precision, efficiency, and noninvasive testing capabilities to ensure the ongoing safety and reliability of essential infrastructure.