Table of Contents

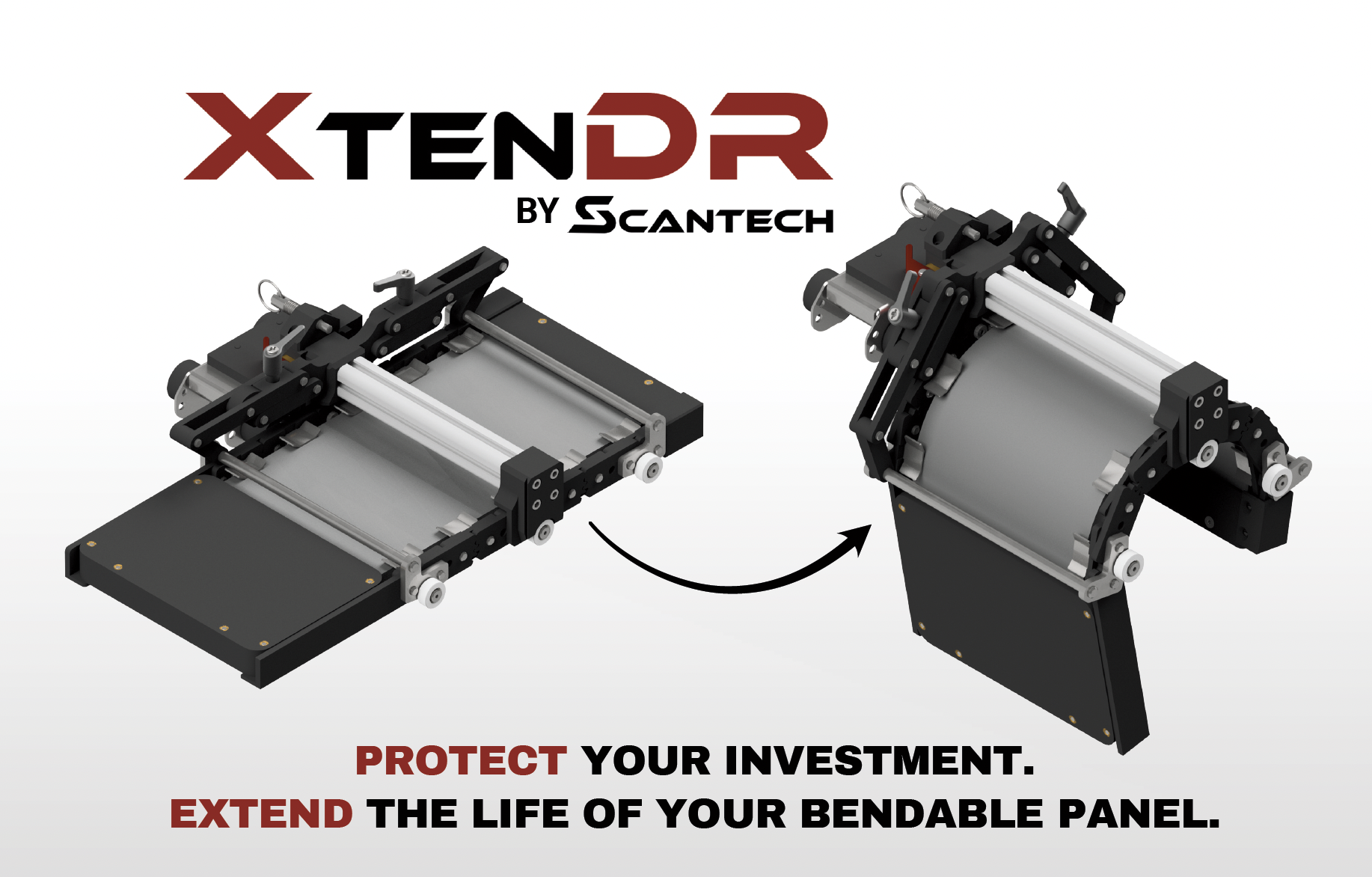

For NDT technicians and resellers using bendable DR panels, XtenDR protects your investment by minimizing stress, fatigue, and reverse bending — extending detector life and lowering replacement costs.

Built around ScanTech’s patent-pending ARC Chain Design, it maintains a uniform curvature during inspection and locks in place for repeatable, field-ready performance.

Why Technicians and Resellers Need a Panel-Protection Solution

Bendable DR panels have made digital radiography practical for curved surfaces — but they’re expensive and fragile.

Every setup and reposition shortens detector life. Over time, fatigue in the imaging layers or micro-fractures in the electronics lead to costly replacements and downtime.

Technicians in oil & gas, energy, and manufacturing sectors are demanding better protection for their flexible detectors, while resellers need a solution that keeps their customers productive and loyal.

How XTenDR Protects Your Panel Investment

XtenDR is not a detector; it’s a precision-engineered support and protection system for bendable DR panels used in industrial NDT.

Its purpose is simple — maintain the right shape, minimize repeat bends, and extend panel life.

Key Features

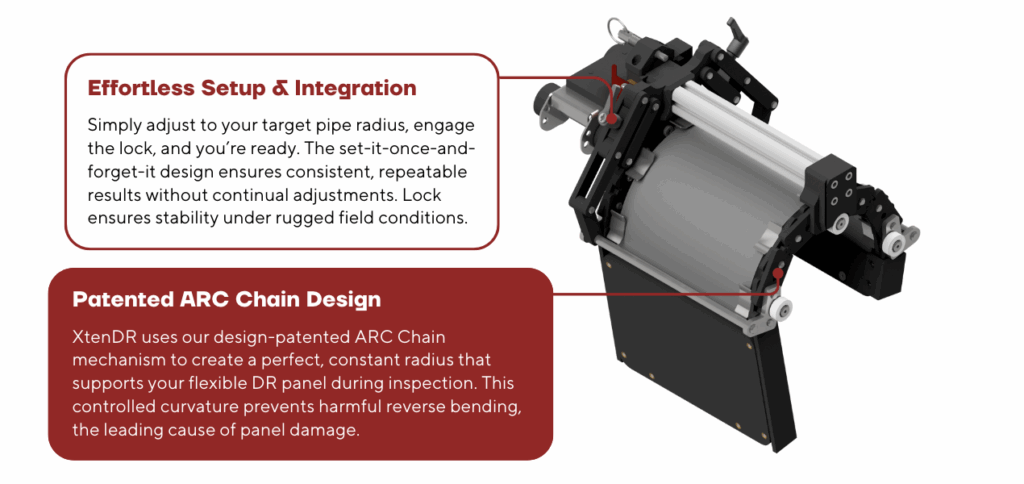

- Patent-Pending ARC Chain Design

A linked-segment mechanism that creates a constant, repeatable radius during inspection.This eliminates reverse or over-bending — the leading causes of detector fatigue and failure.

- Set-It-Once Locking Mechanism

Adjust to your target pipe diameter, lock it, and inspect. The radius remains constant until you change pipe size.

- Uniform Curvature Control

Keeps the panel in a consistent arc, reducing stress points and handling errors.

- Seamless Integration

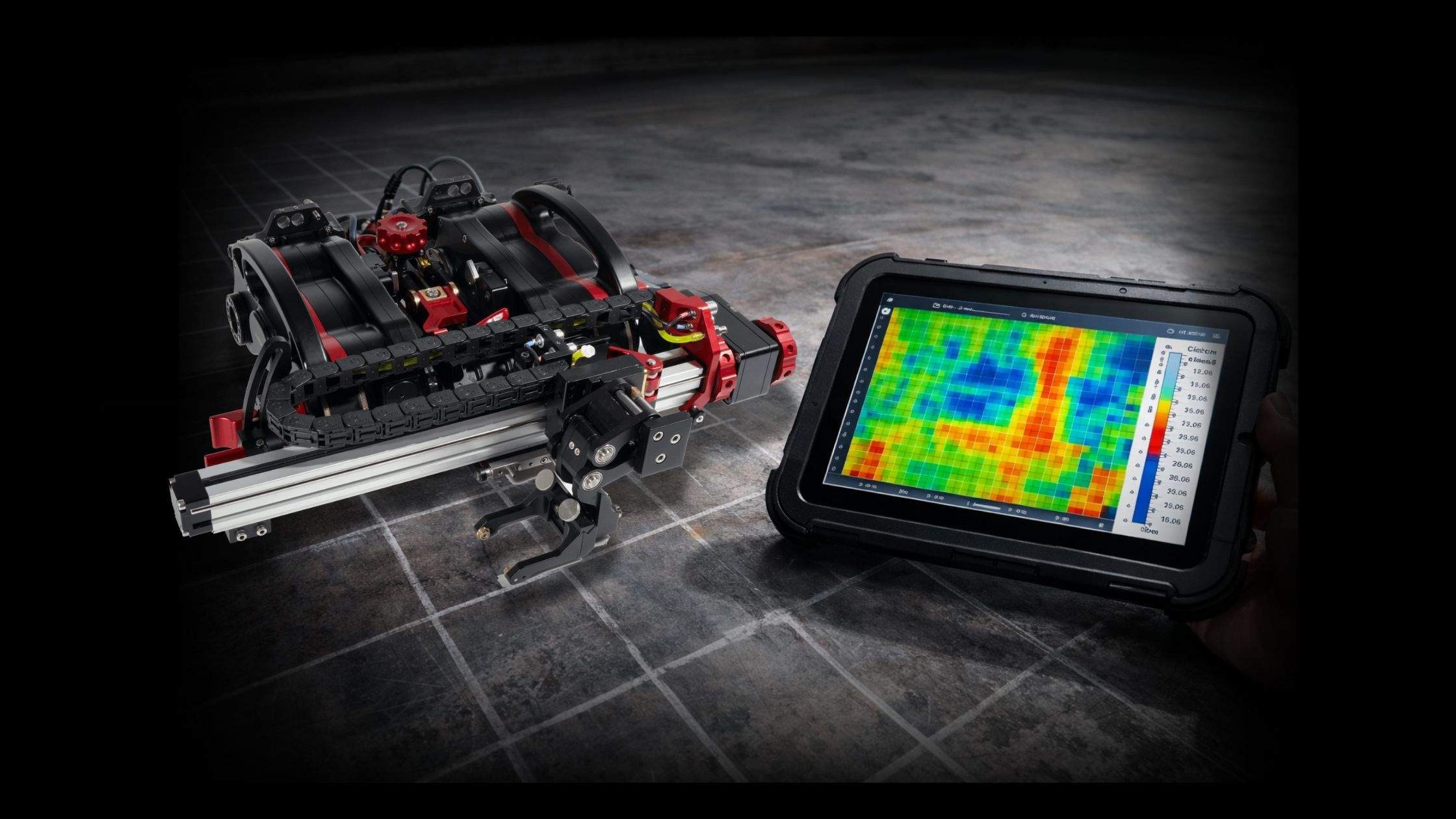

Designed to work directly with the CLIX Chain Scanner for precise, repeatable curved-surface inspections.

- Field-Ready Construction

Durable components withstand vibration, temperature changes, and the rigors of daily field use.

Result: less panel fatigue, longer operational life, and lower replacement frequency — all without changing your inspection workflow.

Why It Matters

For NDT Technicians

-

- Extend the life of your DR panels.

-

- Maintain a stable, repeatable setup for every inspection.

-

- Minimize costly downtime and equipment failure.

For Resellers & Integrators

-

- Offer added value to existing DR customers.

-

- Reduce support calls and panel replacements.

-

- Strengthen your product portfolio with a patent-pending protection solution.

Protect Your Panels. Protect Your Profitability.

Your DR panels are an investment — XtenDR keeps them performing longer.

Request a technical brief or demo at scanndt.com/contact and learn how to integrate XtenDR with our CLIX Chain Scanner system. Interested in becoming a ScanTech Reseller? Learn more HERE!