Table of Contents

Dryer rolls are essential components in industries like paper manufacturing, textiles, and food processing. These components play a vital role in ensuring production efficiency, safety, and cost management. When flaws such as micro-cracks, corrosion, or misalignment go unnoticed, they can lead to unscheduled downtime, reduced productivity, or even safety hazards.

Traditional inspection methods often fail to meet the demands of modern operations. They can be time-consuming, invasive, and prone to errors. To address these challenges, advanced Non-Destructive Testing (NDT) solutions like the D2S Scanner have emerged as a game-changer in dryer roll inspections.

Manufacturers often struggle with outdated inspection methods that fail to meet the demands of modern production environments. One major issue is the inability to detect internal flaws, as subsurface defects can remain hidden until they cause significant damage. Additionally, manual and visual inspections tend to be time-intensive, slowing operations and increasing downtime. Compounding the problem, these methods carry a high potential for human error, where micro-cracks or subtle issues are easily overlooked.

Together, these limitations contribute to delayed maintenance, unexpected failures, and rising operational costs.

How the D2S Scanner Revolutionizes Dryer Roll Inspections

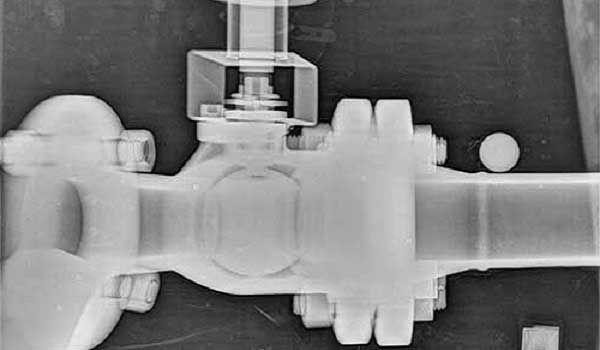

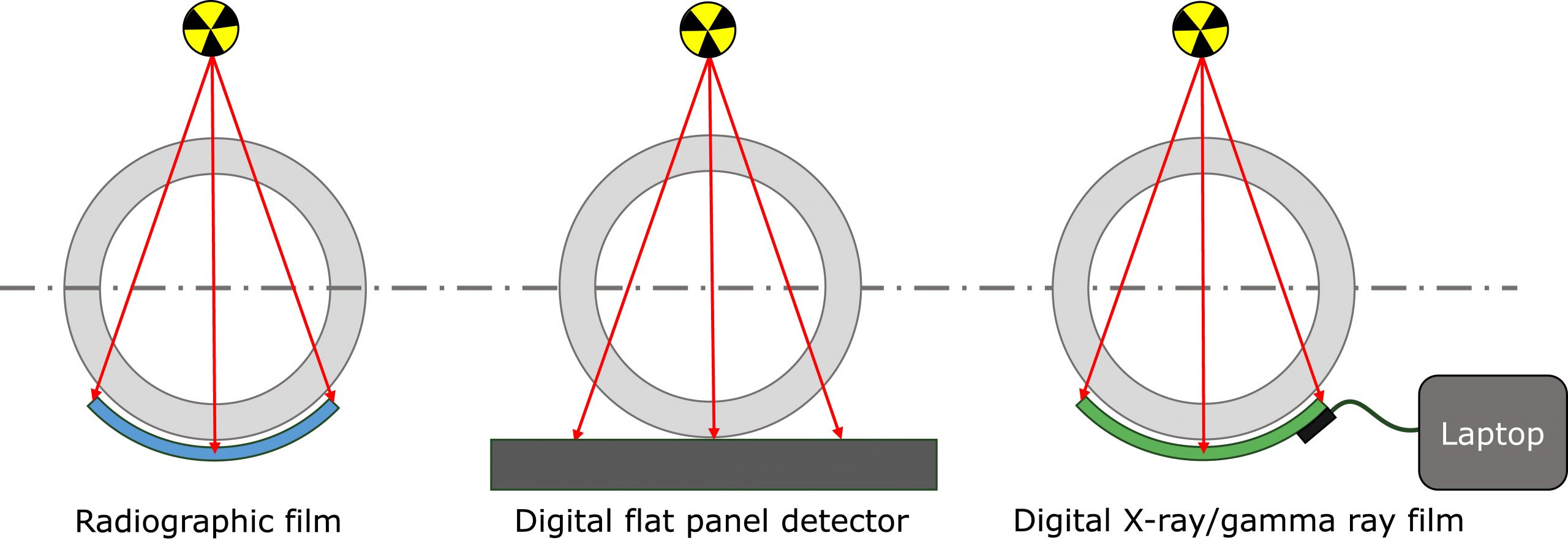

The D2S Scanner offers a transformative solution, addressing the inefficiencies of traditional methods while delivering greater accuracy. This advanced tool features high-resolution imaging, capable of detecting both surface and internal flaws early, significantly reducing the risk of failure. Its non-invasive operation ensures the integrity of equipment remains intact throughout the inspection process.

Speed and efficiency are central benefits, as the scanner accelerates inspections, minimizing costly production downtime. Furthermore, it produces detailed, standardized reports that ensure regulatory compliance, making it an indispensable asset for modern industrial operations.

By combining precision, reliability, and speed, the D2S Scanner sets a new standard for dryer roll inspections.

Key Benefits of NDT for Dryer Roll Inspections

Incorporating Non-Destructive Testing with the D2S Scanner offers significant advantages:

1. Reduced Downtime: Faster, more efficient inspections allow production schedules to remain on track.

2. Cost Savings: Early detection of flaws prevents expensive repairs and extends equipment lifespan.

3. Enhanced Safety: Identifying defects before they escalate reduces risks to equipment and personnel.

4. Compliance and Reporting: Comprehensive insights support adherence to industry standards.

A Real-World Success Story

One paper manufacturer transitioned to the D2S Scanner to streamline their dryer roll inspections. By replacing traditional methods with NDT, the company achieved a 40% reduction in inspection time and increased the operational lifespan of their dryer rolls by 20%. This improvement not only reduced costs but also boosted productivity.

Why Now is the Time to Upgrade

The cost of downtime in high-demand industries is rising, making proactive maintenance more critical than ever. Investing in advanced NDT tools like the D2S Scanner equips companies to detect and address issues before they escalate, saving time and money while ensuring safety.

Don’t wait for failure to force an upgrade. Discover how NDT can revolutionize your dryer roll inspections. Learn more about the D2S Scanner or schedule a demo today to see it in action.