Table of Contents

In industries where equipment reliability is essential, regular inspections are a must. While automation has advanced the field of nondestructive testing (NDT), manual solutions remain indispensable for certain applications. Manual, portable NDT solutions, like handheld scanners, provide unique benefits in scenarios where quick inspections, flexibility, and accessibility are critical. They allow inspectors to conduct fast, on-the-spot checks without setting up complex, automated systems.

This blog explores why manual NDT solutions are ideal for on-the-go inspections and highlights the benefits of using a compact device like the H3 Scanner for efficient corrosion mapping in the field.

The Growing Need for Portable Manual NDT Solutions

As industries expand and equipment becomes more specialized, the demand for quick and versatile inspection tools has increased. Heavy machinery, pipelines, storage tanks, and other assets often operate in challenging environments, where maintaining their structural integrity is crucial. For such cases, portable manual NDT solutions provide a flexible, easy-to-deploy option for inspecting assets without interrupting operations.

The manual NDT approach allows for “spot checks” in critical areas, enabling inspectors to assess corrosion, cracking, or other defects that could compromise safety. These portable scanners are designed to be easy to handle, making them ideal for reaching inaccessible or hard-to-navigate areas.

Key Advantages of Manual, Portable NDT Solutions

Manual NDT solutions offer several advantages that make them a valuable asset in the field. Here’s a closer look at why portable scanners remain an essential part of NDT.

1. Quick Deployment for Fast Inspections

One of the most significant benefits of manual NDT solutions is their fast deployment. Portable scanners require minimal setup, allowing inspectors to perform inspections at a moment’s notice. For industries like oil and gas or manufacturing, where even a brief delay in operations can lead to revenue loss, having a quick and reliable inspection tool is invaluable.

Manual scanners, like the H3 Scanner, can be set up and ready to go within minutes. This allows inspectors to complete routine checks, confirm equipment health, or address sudden concerns without waiting for automated systems to be configured.

2. Versatility and Accessibility

Manual NDT solutions are lightweight and highly portable, which makes them well-suited for inspecting hard-to-reach areas. Inspectors can use these tools to examine corners, welds, joints, or other challenging spots that might be inaccessible to larger automated systems.

For instance, the compact H3 Scanner is specifically designed for ease of use in tight spaces. Its portability allows inspectors to access a wider range of areas in less time, supporting thorough inspections even in confined spaces. With manual scanners, inspectors can evaluate areas that might otherwise be missed, ensuring comprehensive corrosion mapping and defect detection.

3. Ideal for Corrosion Mapping and Small-Site Assessments

Portable scanners are often the best choice for small-site assessments, where inspectors need to capture quick data on corrosion, wall thickness, or small defects. Unlike automated scanners, which are generally intended for extensive surface areas, manual scanners can effectively perform localized inspections. This makes them ideal for corrosion mapping in areas with known vulnerabilities or in high-risk zones.

The H3 Scanner, in particular, is optimized for corrosion mapping. Its compact design and manual controls allow inspectors to capture precise data on corrosion thickness and distribution, enabling them to create accurate corrosion maps on-site. This level of control can be especially beneficial for monitoring equipment over time, tracking areas where corrosion may be worsening, and planning preventive maintenance.

4. Cost-Effectiveness

Automated systems are powerful but can be costly to operate, maintain, and transport. Manual NDT solutions, by contrast, are generally more affordable, offering reliable inspection capabilities at a fraction of the cost. For companies that need regular but straightforward inspections, a manual solution can offer substantial savings.

Portable manual scanners can help lower operational costs, especially in industries that require frequent inspections but don’t necessarily need the continuous data capture that automation provides. With a manual solution, inspectors can perform targeted checks, reducing overall expenses while still ensuring compliance and asset safety.

5. Immediate Feedback for On-the-Spot Decisions

One of the key benefits of using manual NDT solutions is the ability to receive immediate feedback on-site. For field technicians, having instant access to data allows them to make quick decisions, such as whether to halt operations, initiate repairs, or continue monitoring. Immediate data capture is invaluable in industries where rapid response can prevent downtime and maintain productivity.

With the H3 Scanner, inspectors can capture precise corrosion data on-site, allowing them to act on the results right away. This ability to make informed, on-the-spot decisions is essential in fast-paced environments where timing is critical.

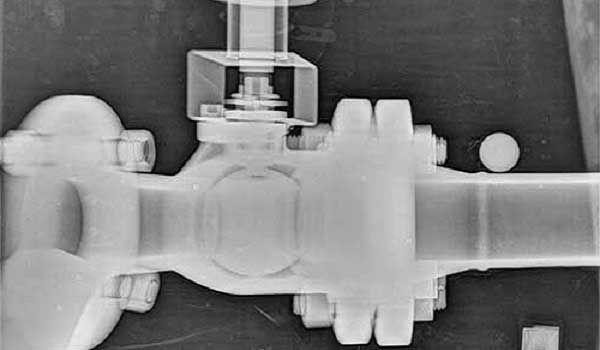

The H3 Scanner: A Powerful Solution for Portable Corrosion Mapping

The H3 Scanner stands out as a leading manual NDT solution for compact, field-ready inspections. Engineered for efficiency, it combines power with portability, making it an ideal tool for corrosion mapping in hard-to-reach or restricted areas. Here’s what makes the H3 Scanner particularly effective:

- Compact Design: The H3 Scanner’s lightweight build makes it easy to transport and use in challenging environments. Inspectors can carry it to various locations with minimal effort, which is especially useful for quick on-site checks.

- Manual Precision: With manual controls, the H3 Scanner offers a high level of precision, allowing inspectors to capture data exactly where they need it. This accuracy is essential for creating detailed corrosion maps that reflect real-time asset conditions.

- User-Friendly Interface: Designed for straightforward use, the H3 Scanner provides an intuitive user interface, enabling inspectors to capture and interpret data quickly. Its simplicity reduces training time, making it easy for field teams to deploy it effectively.

For industries that rely on regular corrosion mapping and defect detection, the H3 Scanner delivers reliable performance without the complexity of automated systems. Its portability, ease of use, and accuracy make it an ideal choice for companies looking to maintain asset integrity and safety in the field.

When to Choose Manual Over Automated NDT Solutions

Both manual and automated NDT solutions have their place in the field. Automated solutions are best for large-scale inspections that require continuous monitoring, while manual solutions shine in scenarios where quick, targeted checks are more practical. If your team needs a flexible, low-cost, and easy-to-use tool for on-the-spot inspections, manual solutions like the H3 Scanner are ideal.

For companies that prioritize accessibility, cost-effectiveness, and fast deployment, manual scanners provide a practical alternative to complex automated systems. These tools enable field teams to inspect assets in real time, ensuring that equipment remains safe, operational, and compliant with industry standards.

Final Thoughts: The Value of Manual NDT Solutions for Field Inspections

Manual NDT solutions continue to play a vital role in industrial maintenance. By choosing portable scanners like the H3 Scanner, companies can perform quick, accessible, and accurate inspections wherever needed. With benefits like quick deployment, cost savings, and immediate feedback, manual solutions are invaluable for maintaining equipment health and supporting long-term asset reliability.

Whether used as a standalone solution or in conjunction with automated systems, manual NDT scanners offer the flexibility and precision that industries need to ensure safety and efficiency. If you’re looking for a portable solution for corrosion mapping and spot-checking in the field, the H3 Scanner is an excellent choice.