Table of Contents

Hydrogen-induced cracking (HIC) is a form of internal damage that occurs when atomic hydrogen diffuses into steel, recombines into molecular hydrogen, and creates pressure that leads to crack formation. Common in wet, sour environments where hydrogen sulfide (H2S) is present, HIC poses a major threat to the integrity of pipelines, storage tanks, and pressure vessels.

This type of cracking is often invisible to the naked eye, developing along mid-wall laminations and progressing over time. Without proper inspection and early detection, HIC can lead to catastrophic failures and unplanned shutdowns.

How Does Hydrogen-Induced Cracking Happen?

Hydrogen atoms diffuse into the steel matrix and collect at trap sites such as inclusions or laminations. When enough atoms gather, they form molecular hydrogen, which cannot diffuse and begins to exert pressure. Over time, this pressure results in blistering and stepwise cracking.

HIC is the result of three interacting elements:

- Hydrogen Source: Most commonly from hydrogen sulfide in sour service environments.

- Steel Susceptibility: Materials with high sulfur content or manufacturing defects are more vulnerable.

- Stress Conditions: Even without external load, internal pressure from recombined hydrogen can trigger cracking.

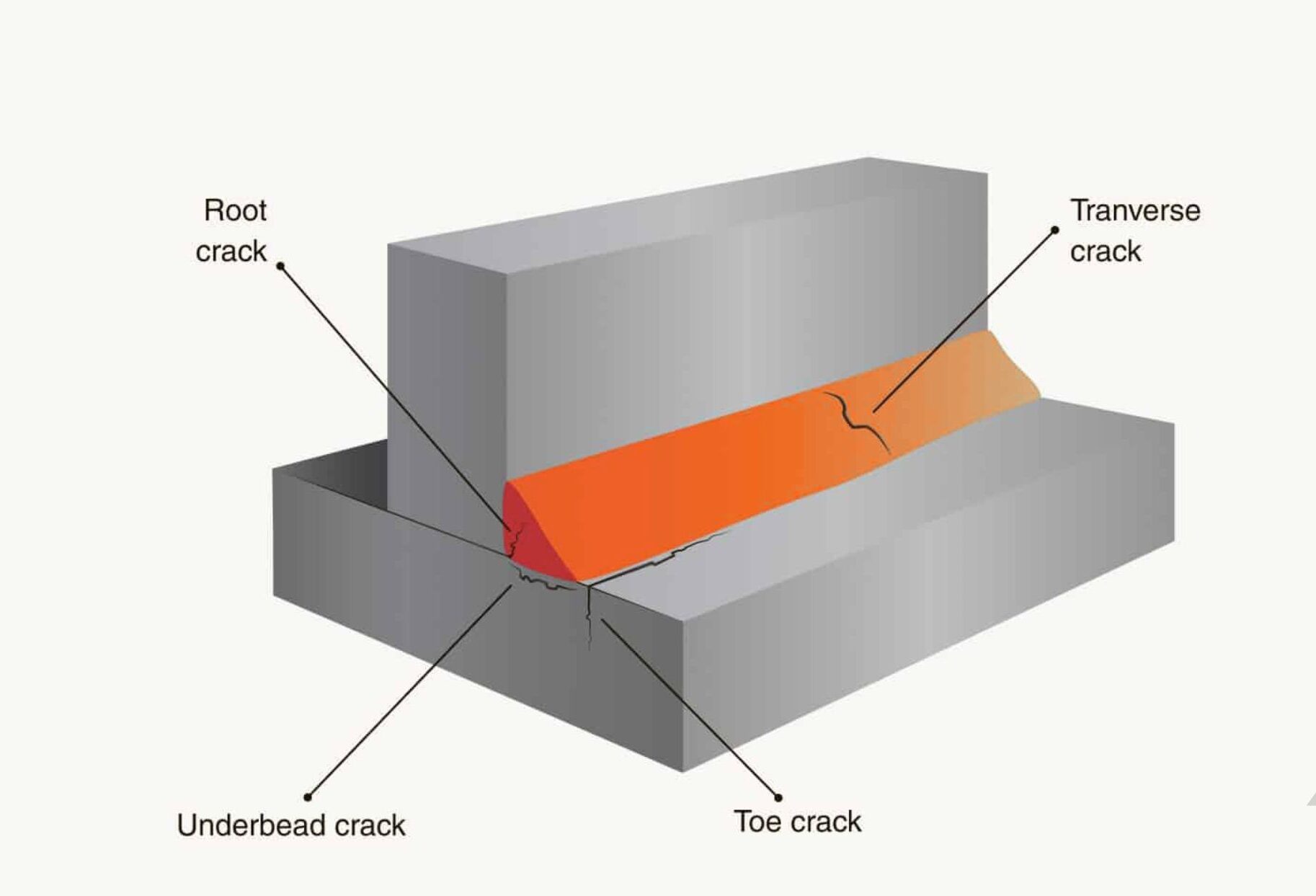

What Does HIC Look Like?

Because the damage is internal and planar, traditional visual inspections are insufficient. Ultrasonic testing (UT) is required to detect and map HIC effectively.

HIC typically forms as:

- Internal cracks parallel to the surface (not surface-breaking)

- Stepwise cracking through the thickness of the steel

- Blistering in extreme cases, creating bulges on the surface

How Ultrasonic Testing Detects HIC

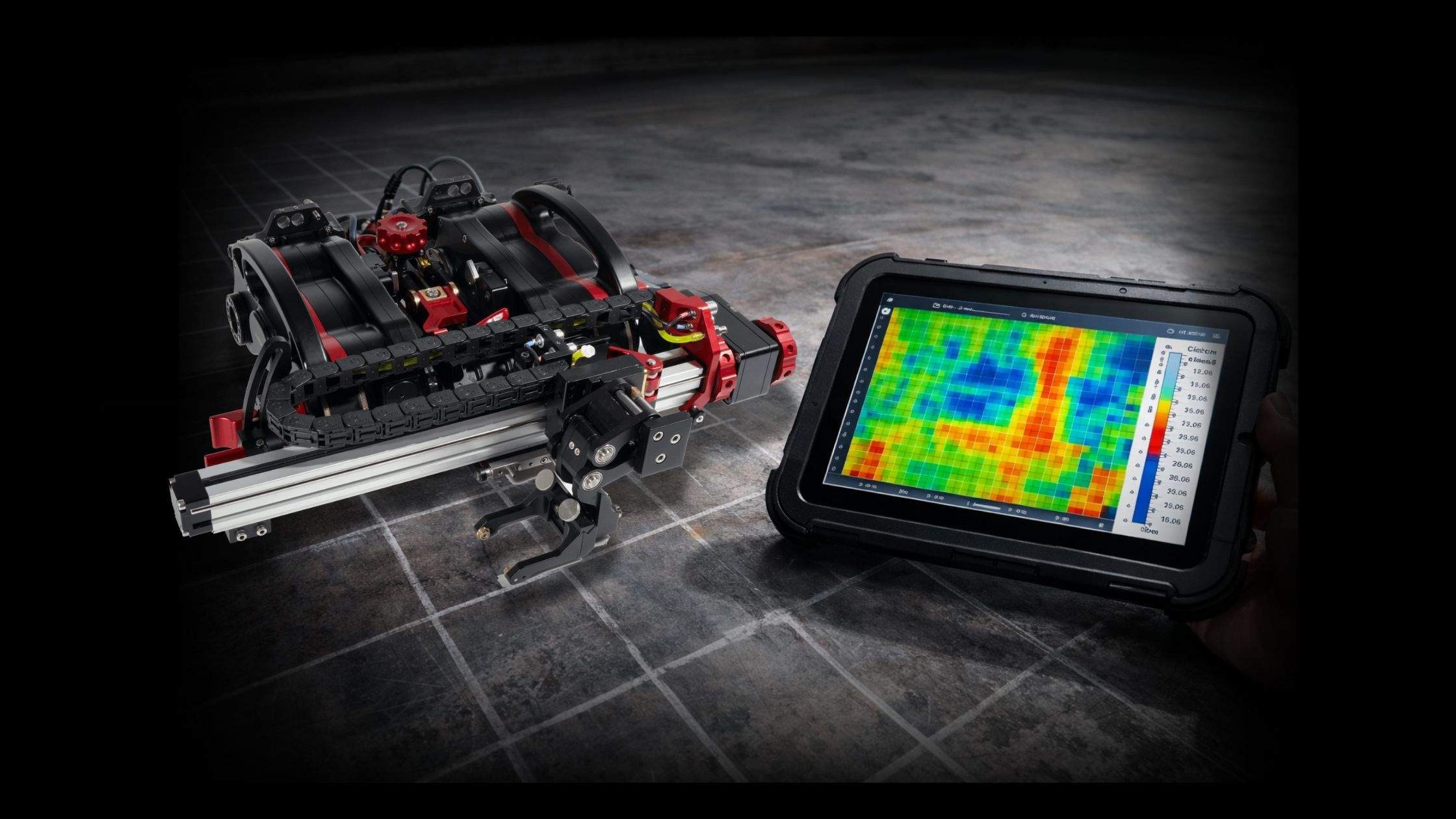

Ultrasonic non-destructive testing (UT NDT) is the industry-standard method for detecting hydrogen-induced cracking.Our XR software includes advanced imaging modes, including Amplitude B-scan, which enhances detection capabilities beyond traditional B-scan or C-scan outputs.

What Is Amplitude B-Scan?

Unlike a standard B-scan that primarily shows geometric representations, Amplitude B-scan adds a critical layer of signal strength visualization. This highlights areas of concern where reflectivity indicates potential cracking, even when geometric signatures may be unclear.

Benefits of Amplitude B-Scan for HIC:

- Reveals subtle internal anomalies with greater clarity

- Displays depth and intensity of flaws

- Enables detection of stepwise cracks that are otherwise hard to identify

- Supports more accurate monitoring over time

This tool is built into ScanTech’s Analyst XR software, which allows inspectors to evaluate damage using real-time, amplitude-enhanced cross-sections. It’s especially vital for HIC, where standard techniques might overlook key indicators of internal pressure damage.

Industries at Risk

Hydrogen-induced cracking is especially prevalent in industries that handle sour hydrocarbons or operate in corrosive environments, including:

- Oil & Gas (Upstream, Midstream, Downstream)

- Petrochemical & Chemical Processing

- Power Generation (especially fossil fuel and thermal plants)

- Storage Tank Farms

ScanTech’s field-ready scanners and Analyst™ software are engineered to deliver actionable HIC inspection data for these environments.

Prevention & Monitoring Strategies

While material selection and proper coatings can help prevent HIC, inspection remains essential to ongoing risk management.

Best Practices Include:

- Choosing steels with low sulfur and high cleanliness

- Regular UT scanning of susceptible assets

- Corrosion mapping to identify hydrogen-rich zones

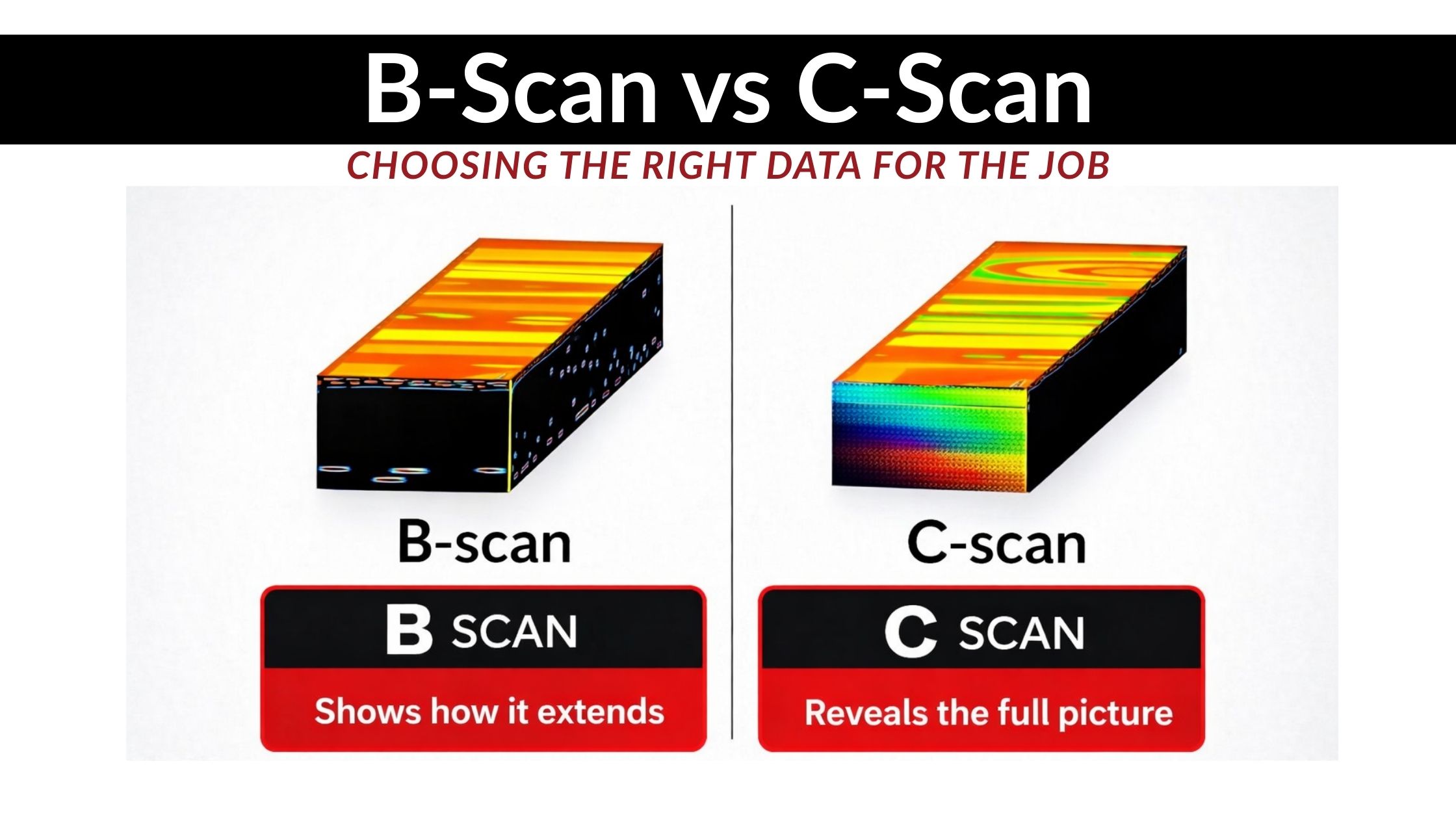

- Documentation and trend analysis with B-scan and C-scan data

Final Thoughts

Hydrogen-induced cracking doesn’t happen overnight —but when left unchecked, it can lead to sudden, severe failures. That’s why detection and monitoring using high-resolution ultrasonic equipment is critical for maintaining safe, reliable operations in H2S environments.

At ScanTech, our UT systems are made for the real world of industrial inspection. From tank floors to pipe walls, we deliver precision tools that keep your operations ahead of failure.

Detect HIC Before It Becomes Critical

Explore ScanTech’s field ready systems designed to help spot and document hydrogen-induced cracking with precision.

Explore Our Field-Ready UT Scanners

Have questions or want to see it in action?

Connect with Our Team to schedule a demo or technical consultation