Table of Contents

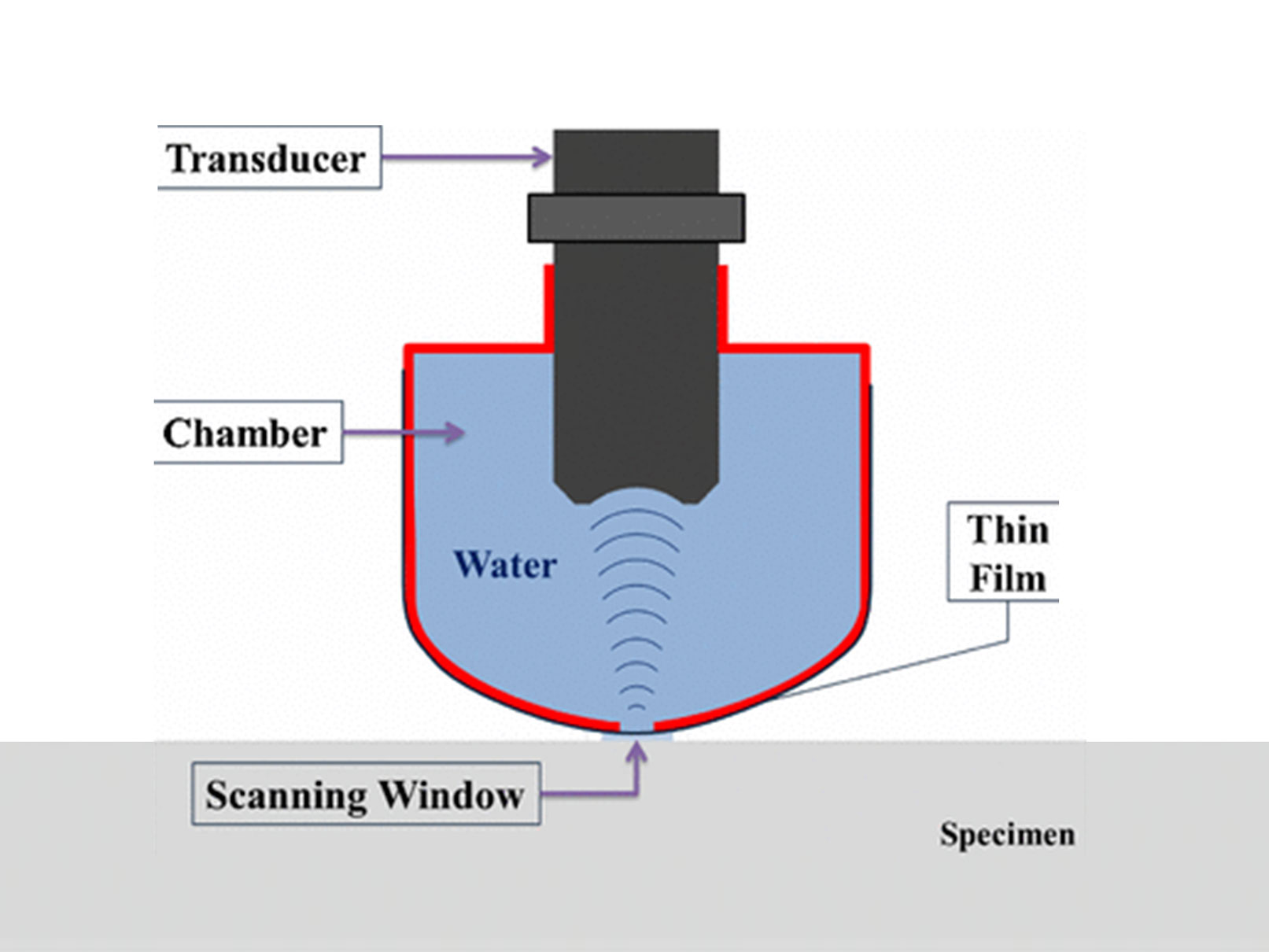

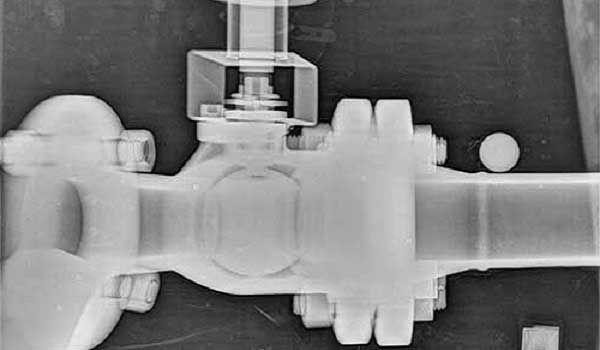

In the world of non-destructive testing (NDT), coupling methods play a critical role in ensuring accurate ultrasonic data transmission. While dry-coupled wheels have gained attention for their convenience, water-based coupling remains the gold standard for precision, reliability, and adaptability. Here’s why ScanTech’s water-coupled technology outshines dry-coupled alternatives.

1. Superior Signal Transmission and Data Accuracy

Water is an excellent medium for ultrasonic waves due to its consistent and uniform acoustic impedance. This ensures:

• Minimal Signal Loss: Water provides a consistent medium between the transducer and the test material, reducing interference and ensuring clear, precise readings.

• Better Coverage: Unlike dry-coupled wheels, water coupling can maintain uniform contact over uneven or rough surfaces, preventing gaps in data collection.

In contrast, dry-coupled wheels often suffer from limited signal penetration due to variations in surface contact or wheel wear over time.

2. Adaptability to Diverse Materials and Applications

Water-coupled systems are highly versatile and can be used on a wide range of materials, including:

• Metals

• Composites

• Plastics

Dry-coupled wheels, while effective for specific applications, may struggle with certain material types or surface conditions, limiting their overall utility in the field.

3. Reduced Maintenance and Longer Lifespan

Water-coupled systems require less frequent maintenance compared to dry-coupled wheels, which are subject to wear and tear from constant physical contact with the material. Additionally:

• Minimal Wear and Tear: Water acts as a natural lubricant, reducing strain on the transducer and associated components.

• Consistent Performance: Unlike dry-coupled wheels, which may degrade over time, water systems maintain consistent performance over extended periods.

4. Enhanced Inspection Capability for Complex Geometries

Dry-coupled wheels are primarily designed for flat or slightly curved surfaces, which can limit their effectiveness in more complex scenarios. Water coupling, on the other hand, excels at:

• Inspecting Irregular Shapes: Its adaptability ensures reliable coupling even on challenging geometries like corners, edges, or tight radii.

• Penetrating Small Features: Water coupling delivers superior resolution for inspecting fine details or small-scale flaws.

5. Cost-Effectiveness Over Time

While dry-coupled wheels may appear cost-efficient initially, their long-term costs can add up due to:

• Frequent maintenance or replacement of worn wheels.

• Potentially higher rates of re-inspection caused by inconsistent coupling or missed flaws.

ScanTech’s water-coupled systems are designed for durability and efficiency, minimizing operational costs over the life of the equipment.

6. Why High-Tech Doesn’t Always Mean High Performance

Dry-coupled wheels are often marketed as cutting-edge solutions, but this doesn’t always equate to better results. The technology:

• Relies heavily on surface conditions, which can compromise accuracy.

• Faces limitations in applications requiring deep penetration or inspection of thick materials.

Water coupling, while more traditional, consistently delivers reliable, high-quality data across a broader range of applications. In an industry where precision matters most, proven performance outweighs marketing hype.

Trust the Reliability of Water-Coupled Solutions

While dry-coupled wheels may offer convenience, ScanTech’s water-coupled ultrasonic systems deliver unmatched precision, versatility, and cost-effectiveness. By leveraging water as a coupling medium, our technology ensures inspectors achieve reliable, repeatable results in even the most challenging environments.

At ScanTech, we prioritize what works in the real world—not just what looks good on paper. Choose the proven solution that continues to set the standard in NDT inspections.