Table of Contents

Ultrasonic Testing (UT Testing) is a cornerstone of nondestructive testing (NDT) methods, essential for industries focused on safety and reliability. At ScanTech Instruments, we specialize in developing advanced robotic NDT imaging systems, including cutting-edge ultrasonic scanners designed to meet the toughest industrial challenges.

What is UT Testing?

UT Testing uses high-frequency sound waves to evaluate material properties, detect imperfections, and ensure structural integrity. This nondestructive method is ideal for maintaining the functionality of critical components without compromising their usability.

How It Works

Sound waves travel through materials, and any discontinuities, such as cracks or voids, reflect the waves back to a receiver. These reflections are then analyzed to determine the size, type, and location of flaws, ensuring accurate assessments.

Applications of Ultrasonic Testing

At ScanTech Instruments, our robotic UT systems are designed for a range of industrial applications, providing unmatched precision and reliability:

•Aerospace: Inspection of aircraft components to detect potential material failures.

•Oil and Gas: Ensuring pipeline integrity and monitoring corrosion in storage tanks.

•Power Generation: Verifying weld quality in boilers, turbines, and other critical systems.

•Pulp and Paper: Identifying thinning in dryer rolls and other production equipment.

•Manufacturing: Supporting quality assurance in production processes for various materials.

Benefits of Ultrasonic Testing with ScanTech Systems

•Nondestructive Approach: Preserve material integrity while gaining valuable insights.

•High Sensitivity: Detect even the smallest flaws in metals, composites, and polymers.

•Versatility: Adaptable to a wide range of materials and inspection scenarios.

•Real-Time Analysis: Instant feedback enables faster decision-making.

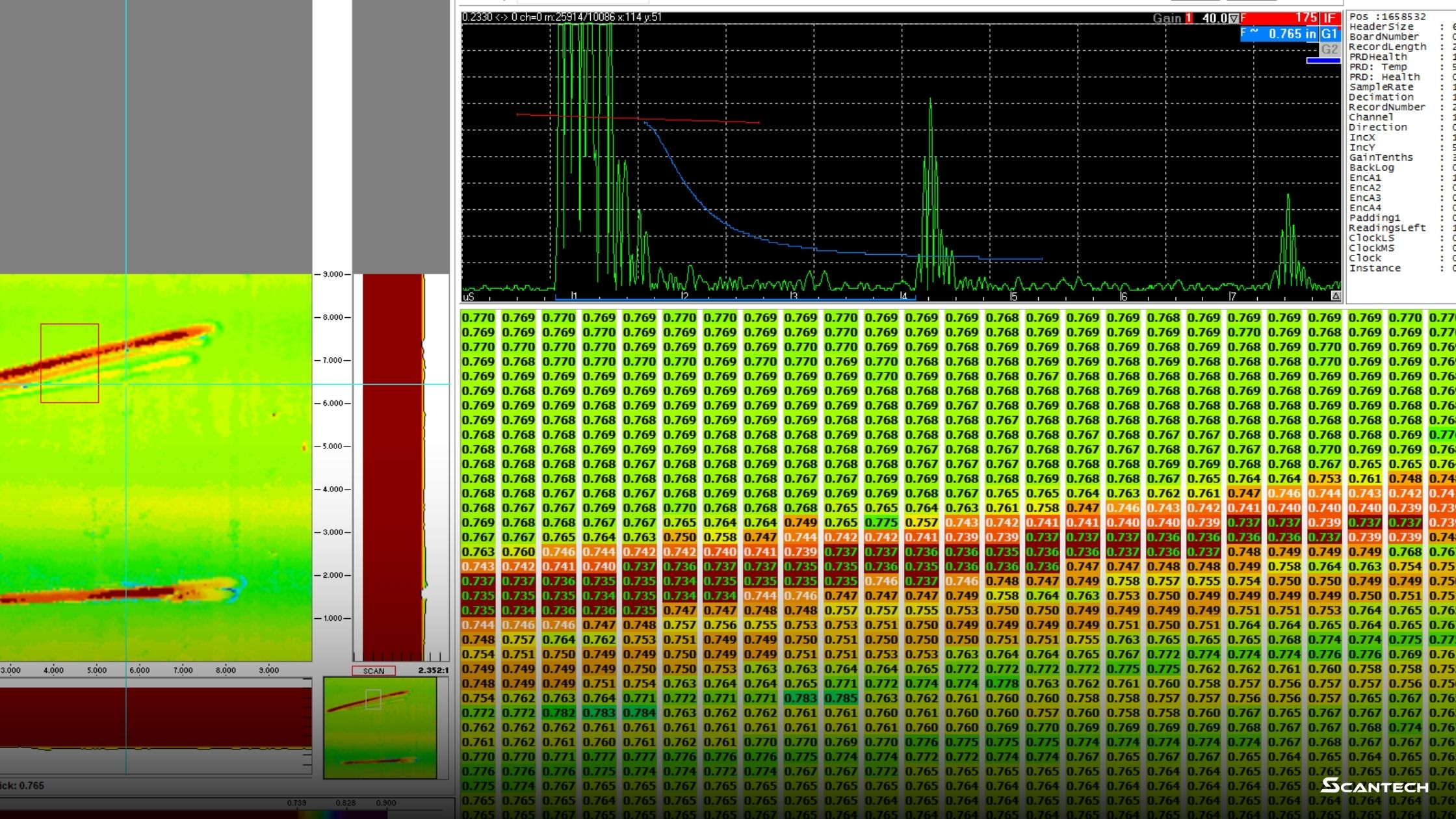

•Advanced Technology: Our systems are engineered for seamless integration with Analyst software, enhancing data acquisition and reporting.

Techniques in Ultrasonic Testing

At ScanTech, we offer innovative ultrasonic systems for multiple testing methods:

Pulse-Echo Testing

Ideal for detecting defects by analyzing sound wave reflections.

Phased Array Ultrasonic Testing (PAUT)

Delivers high-resolution imaging for precise defect characterization.

Time of Flight Diffraction (TOFD)

Ensures accurate defect sizing and location for critical applications.

Immersion Testing

Optimal for complex geometries, ensuring uniform sound wave transmission through water.

Overcoming Common Challenges

ScanTech systems are designed to address common issues in ultrasonic testing:

•Surface Preparation: Our scanners ensure accurate results even on imperfect surfaces.

•Operator Dependency: User-friendly designs and intuitive Analyst software reduce the learning curve.

•Material Limitations: Robust solutions for challenging materials, including coarse-grained alloys.

•Environmental Factors: Rugged designs withstand harsh industrial conditions.

Emerging Trends in Ultrasonic Testing with ScanTech

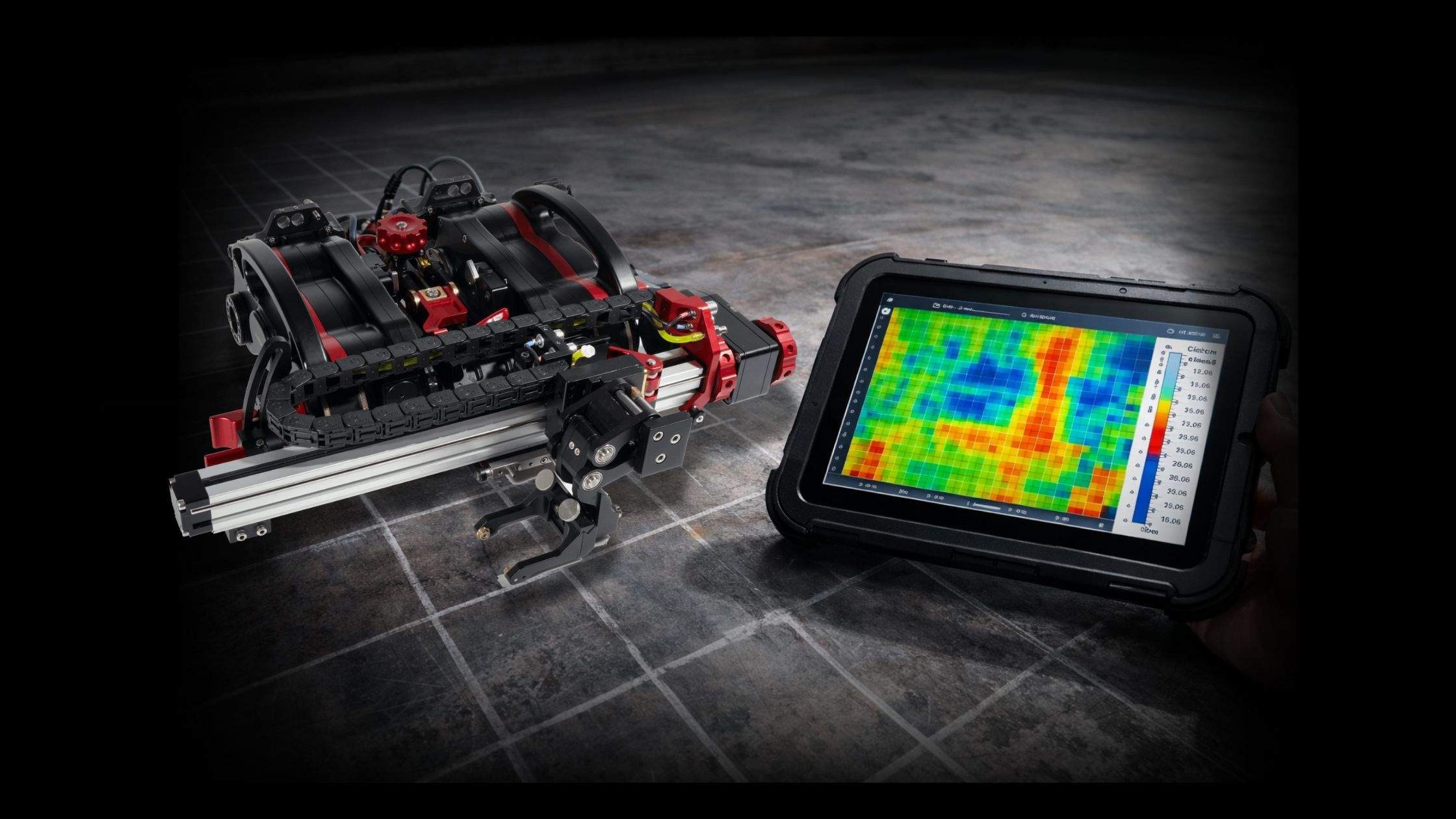

Robotic Scanners

Our automated systems improve safety by reducing human exposure in hazardous environments.

Enhanced Portability

Lightweight, modular designs make it easier to conduct inspections in hard-to-reach areas.

Real-Time Data Analysis

Integration with Analyst software allows for immediate defect visualization and reporting.

Increased Versatility

From tank crawlers to manual handheld systems, we offer solutions tailored to diverse industry needs.

Why Choose ScanTech for Ultrasonic Testing?

At ScanTech Instruments, we understand that reliability, precision, and ease of use are critical in NDT applications. Our ultrasonic systems are designed and manufactured in-house in Texas, ensuring unmatched quality control and innovation. Every system we create is tailored to meet real-world challenges, giving you the confidence to trust your inspections to the best in the industry.

Ultrasonic Testing is indispensable for maintaining safety and reliability across industries. With ScanTech Instruments’ robotic NDT systems, you gain access to state-of-the-art solutions that deliver precision, durability, and ease of use. Whether you’re inspecting pipelines, ensuring weld quality, or maintaining production equipment, our advanced UT solutions ensure your operations run smoothly.

Contact ScanTech Instruments today to learn more about how our ultrasonic testing systems can meet your industry’s needs.