Introduction to Ultrasonic Testing in NDT

Ultrasonic testing (UT) is a widely used nondestructive testing (NDT) method for detecting flaws, measuring thickness, and assessing material integrity in industrial applications. Industries such as oil & gas, power generation, and manufacturing rely on UT for its accuracy and efficiency.

One critical application of UT is API 653 tank inspection, which ensures the structural integrity of aboveground storage tanks (ASTs). With advancements in UT technology, companies can now use B-scan, C-scan, and advanced corrosion mapping software to generate instant reports and comply with industry standards.

This blog explores the role of ultrasonic testing in NDT, its importance in API 653 compliance, and the latest UT scanning solutions.

UT Testing in API 653 Tank Inspections

API 653 sets the inspection, repair, alteration, and reconstruction requirements for aboveground storage tanks (ASTs). Regular UT testing is essential for identifying corrosion, pitting, and wall thickness loss before they compromise tank integrity.

How UT Supports API 653 Compliance:

- Corrosion Detection: Identifies areas of metal loss and prevents failures.

- Wall Thickness Measurement: Ensures tanks meet minimum thickness requirements.

- Automated Reporting: Advanced B-scan software generates reports instantly, aligning with API 653 regulations.

Our Analyst B-scan software includes a built-in API 653 algorithm, enabling inspectors to produce detailed reports in seconds. This ensures faster decision-making and improved compliance with industry standards.

Ultrasonic Testing Scanning Technologies & Software Solutions

Standalone UT Scanners vs. Complete Systems

When selecting a UT testing system, companies can choose between:

✔️ Standalone UT scanners that integrate with third-party software and UT gauges.

✔️ Complete UT systems with built-in software for full automation.

Our UT solutions offer flexibility, allowing users to pair scanners with external UT equipment or use our complete systems with integrated software for streamlined inspections.

Analyst B-Scan Software: API 653 Compliance

- Built-in API 653 algorithm for rapid tank inspection reports.

- Provides B-scan imaging for corrosion detection.

- Suitable for tanks, pipes, and vessel inspections.

Analyst XR & X: Corrosion Mapping & B-Scan Imaging

- Analyst XR software: Used for corrosion mapping in pipelines and tanks.

- Analyst X software: Specializes in B-scan imaging for detailed flaw detection.

Both software solutions provide high-resolution data, ensuring precise NDT inspections in compliance with API 653 and other industry standards.

D2S: Specialty UT Scanner for Dryer Roll Inspection

- Designed specifically for dryer roll inspections in the paper industry.

- Ensures early defect detection and optimized maintenance planning.

XR & Vertex: Optimized for Pipe Inspections

- Used in pipeline integrity assessments and corrosion mapping.

- Powered by Analyst XR C-scan software, which includes a built-in B31G algorithm for pipeline defect evaluation.

B31G compliance is crucial for assessing pipeline fitness-for-service and determining safe operating conditions.

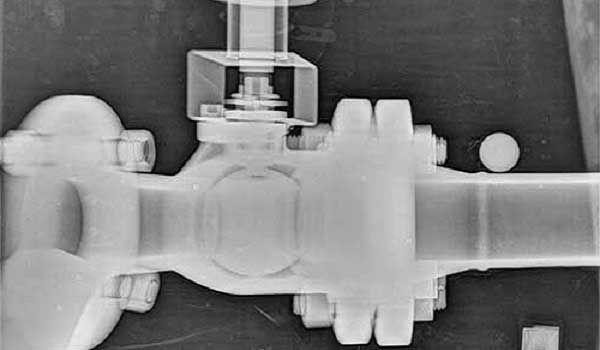

UT Testing for Weld Inspection: Radix Weld Scanner

Weld inspections are critical in ensuring the safety and reliability of pipelines, pressure vessels, and structural components. The Radix Weld Scanner is an advanced TOFD (Time-of-Flight Diffraction) and Phased Array (PA) scanner designed for accurate weld flaw detection.

Key Features of Radix Weld Scanner:

- Supports TOFD and Phased Array (PA) ultrasonic testing.

- Provides high-resolution weld imaging for flaw detection.

- Compatible with external UT units like OmniScan.

Important Note: Radix does NOT include ScanTech software for TOFD or Phased Array. Users must connect the scanner to an external UT machine like OmniScan for full functionality.

Why Choose Our Ultrasonic Testing NDT Solutions?

For industries requiring API 653 compliance, pipeline integrity assessments, and advanced weld inspections, our ultrasonic testing (UT) scanners and software solutions provide unmatched accuracy and efficiency.

✔️ Built-in API 653 & B31G algorithms for instant compliance reporting.

✔️ Versatile UT solutions for tanks, pipes, vessels, and welds.

✔️ Standalone & complete systems to fit various inspection needs.

Ready to optimize your NDT inspections? Contact us today for a demo or consultation!