The Power of Ultrasonic Testing in Non-Destructive Testing

Non-destructive testing (NDT) is a cornerstone of safety and efficiency across countless industries. From oil and gas to aerospace and manufacturing, NDT provides the tools to evaluate critical components without causing damage. Among the many methods available, ultrasonic testing stands out for its precision, versatility, and ability to uncover hidden flaws.

What Is Ultrasonic Testing and How Does It Work?

Ultrasonic testing uses high-frequency sound waves to probe materials for imperfections. These sound waves travel through the material, and any inconsistencies, such as cracks or corrosion, cause reflections that can be detected and analyzed. This process ensures that essential assets, like pipelines, welds, and pressure vessels, remain reliable and safe to use.

Why Ultrasonic Testing Matters for Safety and Efficiency

One of the most significant benefits of ultrasonic testing is its ability to enhance safety. By identifying flaws early, it helps prevent equipment failures that could lead to costly downtime or even catastrophic accidents. It’s also an incredibly efficient solution, allowing inspections to be performed without dismantling equipment, reducing the time and expense associated with repairs or replacements.

The Versatility of Ultrasonic Testing Across Industries

Ultrasonic testing is equally effective for inspecting the intricate geometry of turbine blades as it is for evaluating the structural integrity of large storage tanks. This adaptability makes it an indispensable tool for industries where precision and reliability are non-negotiable.

Redefining Ultrasonic Testing with Innovative Solutions

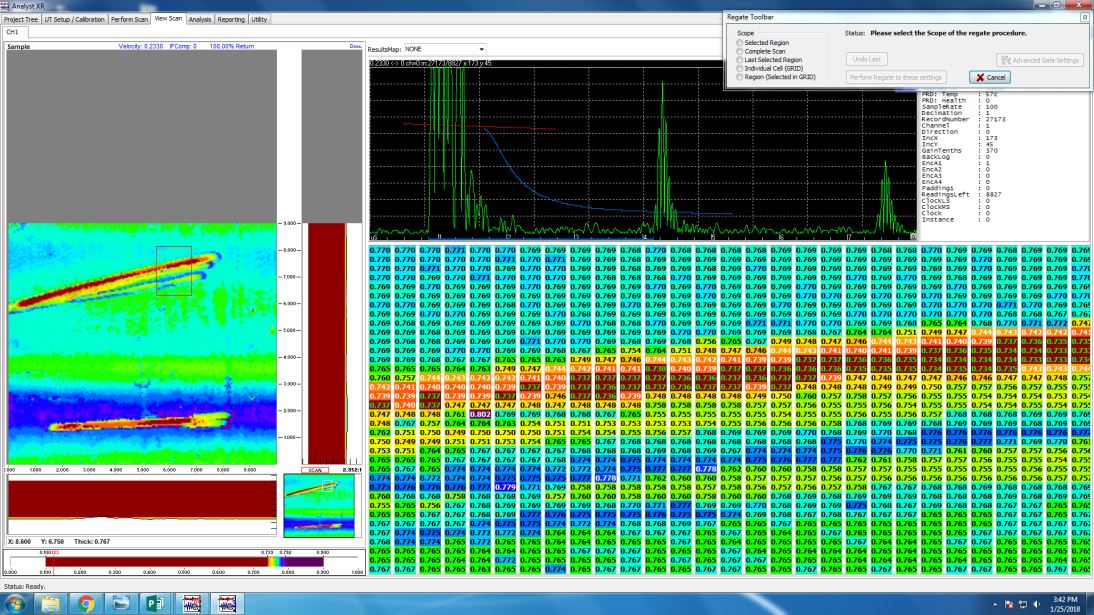

At ScanTech Instruments, we’re redefining what’s possible in ultrasonic testing. Our robotic NDT imaging systems are engineered to provide unmatched accuracy, ease of use, and durability in the most demanding environments. Designed and manufactured in the USA, our systems are tailored to meet the real-world challenges faced by technicians and inspection professionals. Features like modular design, tool-free configurations, and seamless integration with proprietary software ensure that every inspection is both efficient and reliable.

The Future of Ultrasonic Testing

Innovation drives us forward. As technology continues to evolve, so does the potential for ultrasonic testing to unlock new possibilities. Advanced robotics, precision sensors, and intuitive software are shaping the future of NDT, enabling industries to push boundaries while prioritizing safety and efficiency.

Ultrasonic testing is more than a method—it’s a commitment to excellence. At ScanTech Instruments, we’re proud to lead the way with solutions that empower industries to innovate, grow, and succeed.