Turnaround planning is one of the most effective ways to reduce re-scans and rental spend across NDT inspections. When inspection managers define data quality standards, track equipment utilization, and align scanner deployment before shutdown, they minimize downtime and avoid unnecessary rental costs.

Why Turnaround Planning Drives Cost Efficiency

Every hour of plant downtime has a financial cost. During refinery or power-generation turnarounds, poor planning leads to idle crews, repeated scans, and inflated equipment rentals.

-

-

Managers and NDT Level III inspectors face three recurring issues:

-

Inconsistent data: Missed spots require re-scanning.

-

Idle scanners: Rentals sit unused between scopes.

-

Unverified coupling: Inadequate probe checks cause invalid data.

-

Strategic turnaround planning solves these challenges with structured sequencing and defined quality checkpoints.

Step-by-Step: How to Reduce Re-Scans and Rental Spend

1. Establish Data Quality Standards Early

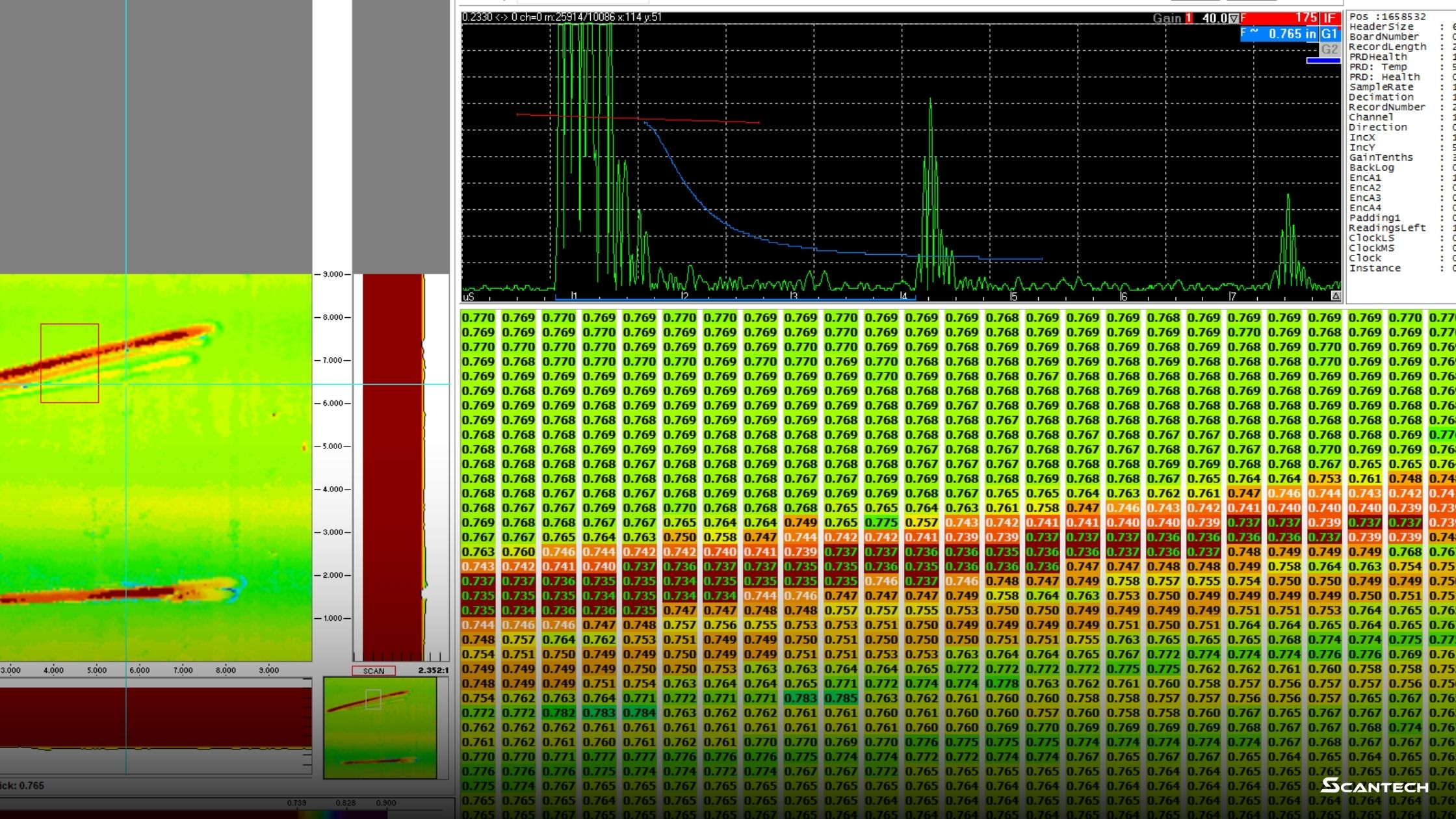

Before inspections begin, document what qualifies as acceptable coupling and signal quality. Consistent standards across shifts reduce duplicate work later.

2. Use Pre-Job Checklists

Standardized checklists reduce technician error and improve setup repeatability. Each scanner session should include encoder verification and coupling confirmation.

3. Track Equipment Utilization

Log every scanner’s operational time. If rentals are under 50 % utilized, consider redistributing or replacing them with owned equipment in future outages.

4. Align Inspection Schedules by Asset Priority

Start with API 653 or code-critical assets first. Sequencing inspections by risk priority ensures the highest-value assets are verified early and avoids last-minute bottlenecks.

5. Evaluate Rental vs Ownership ROI

Owning scanners can cut recurring rental costs by 40 – 60 % after two turnarounds. This approach also improves readiness—your teams aren’t waiting on vendor availability.

The Bigger Picture

Turnaround planning isn’t just scheduling—it’s a performance discipline.

By integrating project management with inspection workflows, companies reduce re-scans, control costs, and deliver faster reports.

For deeper insight into inspection planning and data workflows:

Ready to Improve Your Next Turnaround?

Planning is the most valuable inspection tool you own. By tightening workflow, standardizing data verification, and tracking utilization, you not only reduce re-scans—but also uncover where your rental budget can turn into capital investment.

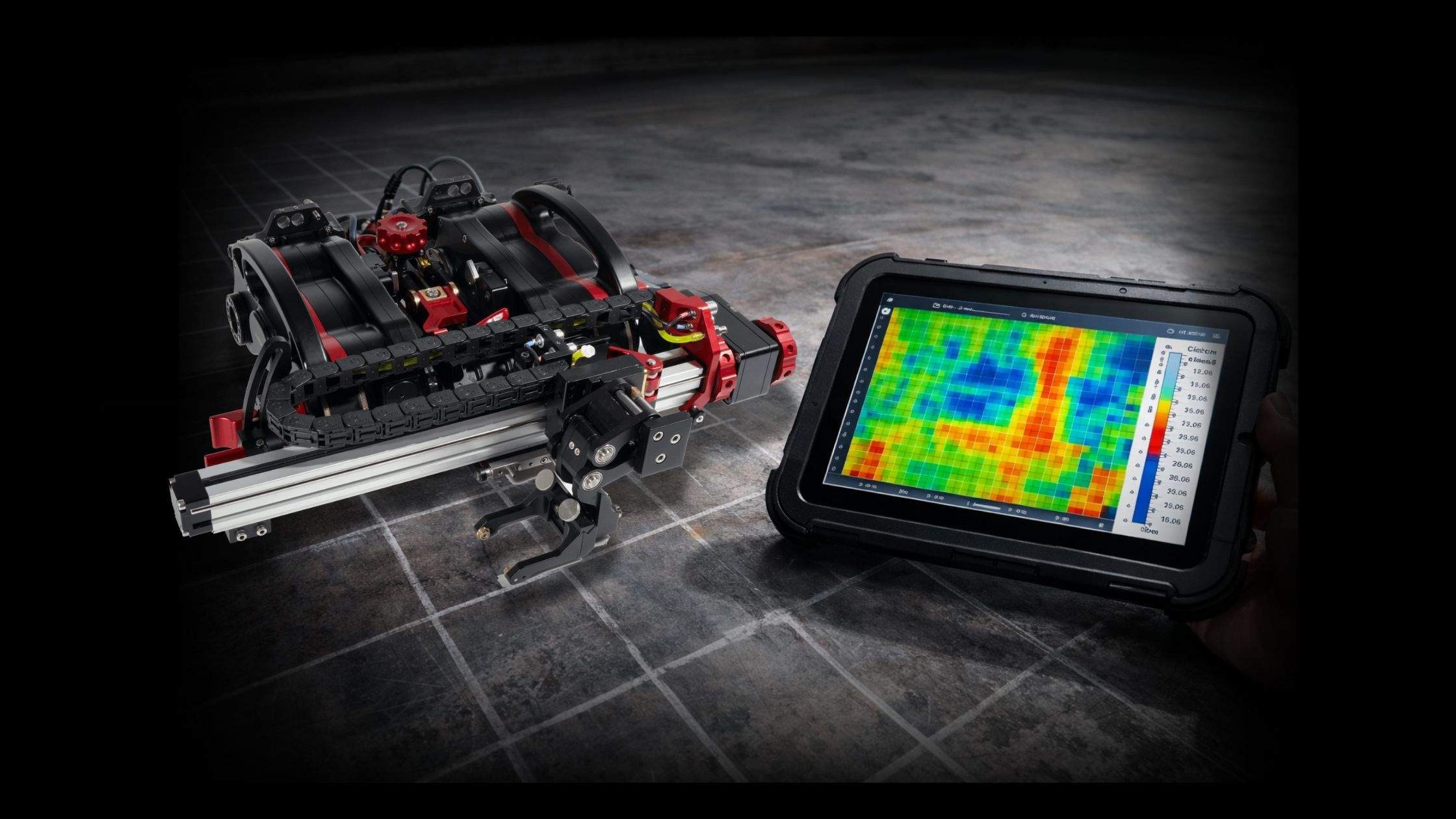

For a deeper look at data-driven inspection workflows, explore our blog on Corrosion Mapping.