Table of Contents

Why Re-Scans Cost More Than You Think

Redundant inspections — or re-scans — are one of the biggest hidden cost drivers in non-destructive testing (NDT). When data quality is poor, coverage is incomplete, or inspection decisions lack confidence, teams often return to the field for a second pass. That second visit doesn’t just add technician hours — it adds downtime, travel costs, lost productivity, and schedule risk.

But what if re-scans weren’t treated as inevitable? What if teams approached inspection with a mindset that emphasizes first-time quality?

Leading inspection teams are doing precisely that by treating data quality as a cost-savings strategy — reducing rework, improving decision confidence, and shortening maintenance windows across assets.

This article dives into:

- The real cost breakdown of re-scans

- Why defects get missed in the first place

- How strong workflows + tooling reduce repeat visits

- Practical estimate and checklist templates you can use immediately

1. The Real Cost Breakdown of Re-Scans

Most organizations think inspection costs begin and end with the time a technician spends scanning. In reality, the true cost of re-scans includes:

Technician Labor: Re-scans mean additional field time, often at overtime rates or added travel.

Asset Downtime: Waiting for re-scans can delay critical maintenance or put production on hold — costs that quickly eclipse inspection fees.

Logistics & Mobilization: Repeat deployment involves vehicle travel, rigging equipment, permits, and staging/disassembly time.

Indirect Expenses: Extended outages may disrupt downstream operations, impacting supply chains or contract obligations.

Risk Premiums: Late defect detection can increase safety risk and premium costs for insurance or compliance programs.

Market insights show that indirect inspection costs — such as access setup, scaffolding, and planned outages — often far exceed the nominal inspection cost itself, especially in complex industrial environments. Tackling the root cause of re-scans delivers measurable savings across an inspection program.

2. Where Defects Hide — And Why They Trigger Re-Scans

Defects don’t always appear where you expect them. In NDT, common hidden flaw regions include:

- Geometry transitions such as weld toes or curved surfaces

- **Coating edges or insulation interfaces where corrosion hides beneath

- **Micro-cracks in heat-affected zones

- **Material inhomogeneities that mask signals in certain orientations

Even sophisticated tools like phased array ultrasonic testing or digital radiography can miss or misinterpret flaws when coverage isn’t complete or signal quality is compromised.

That’s why many re-inspections happen not due to manpower alone, but because of data gaps that could have been avoided with better setup, consistent motion, and smarter scan planning.

3. Workflow + Tooling: The Combo That Prevents Re-Scans

Reducing re-scans starts with combining disciplined workflows with effective tooling.

A. Structured Coverage Plans

Before any inspection begins, define a scan path that ensures complete coverage. Grid plans, raster scans, and encoded motion paths reduce the risk of unscanned regions — especially on complex geometry.

Encoded path control ensures one pass delivers predictable, repeatable results. This reduces uncertainty in decision making.

B. Robust Acquisition Tools

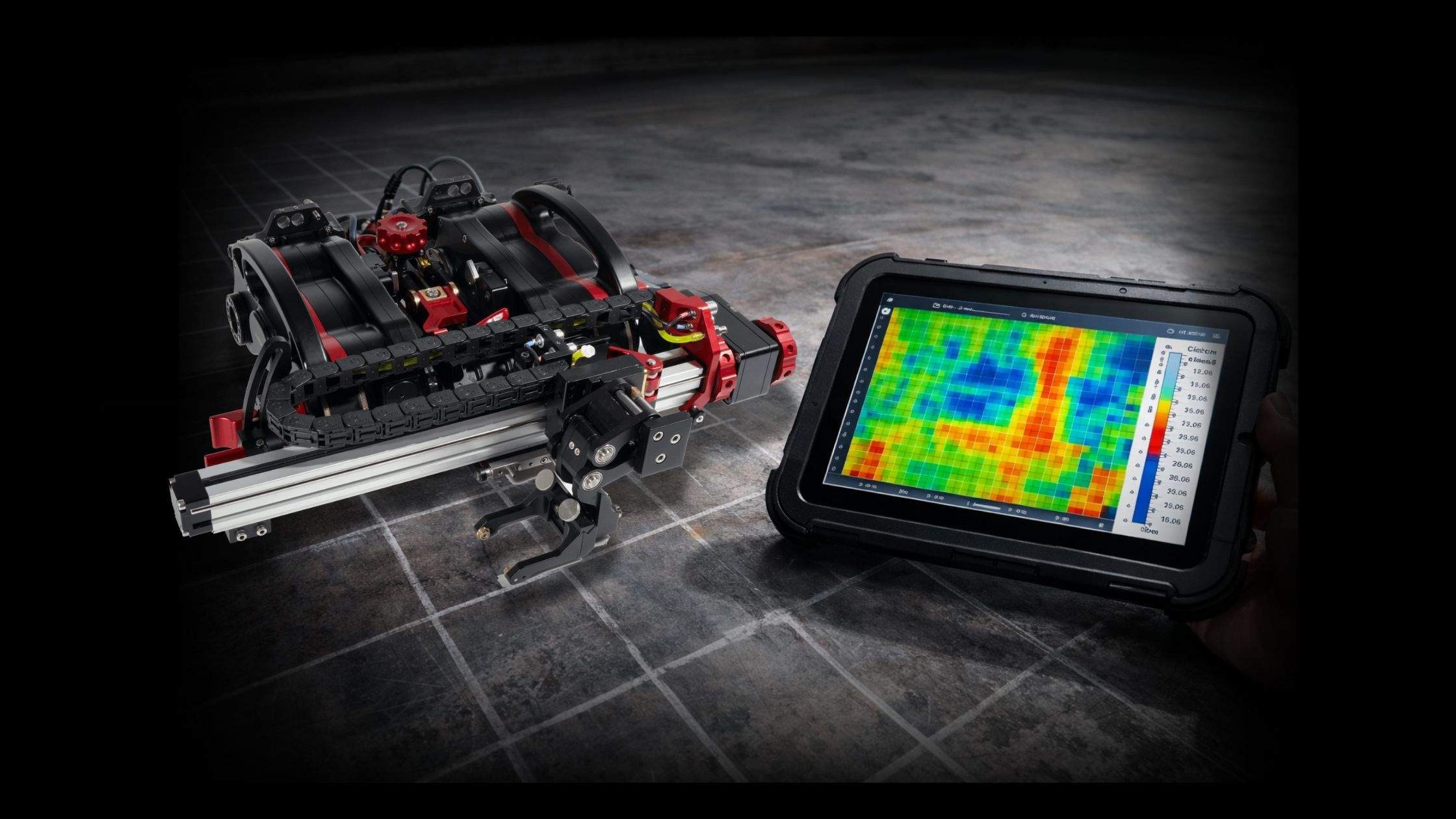

Modern inspection tools deliver better raw data.

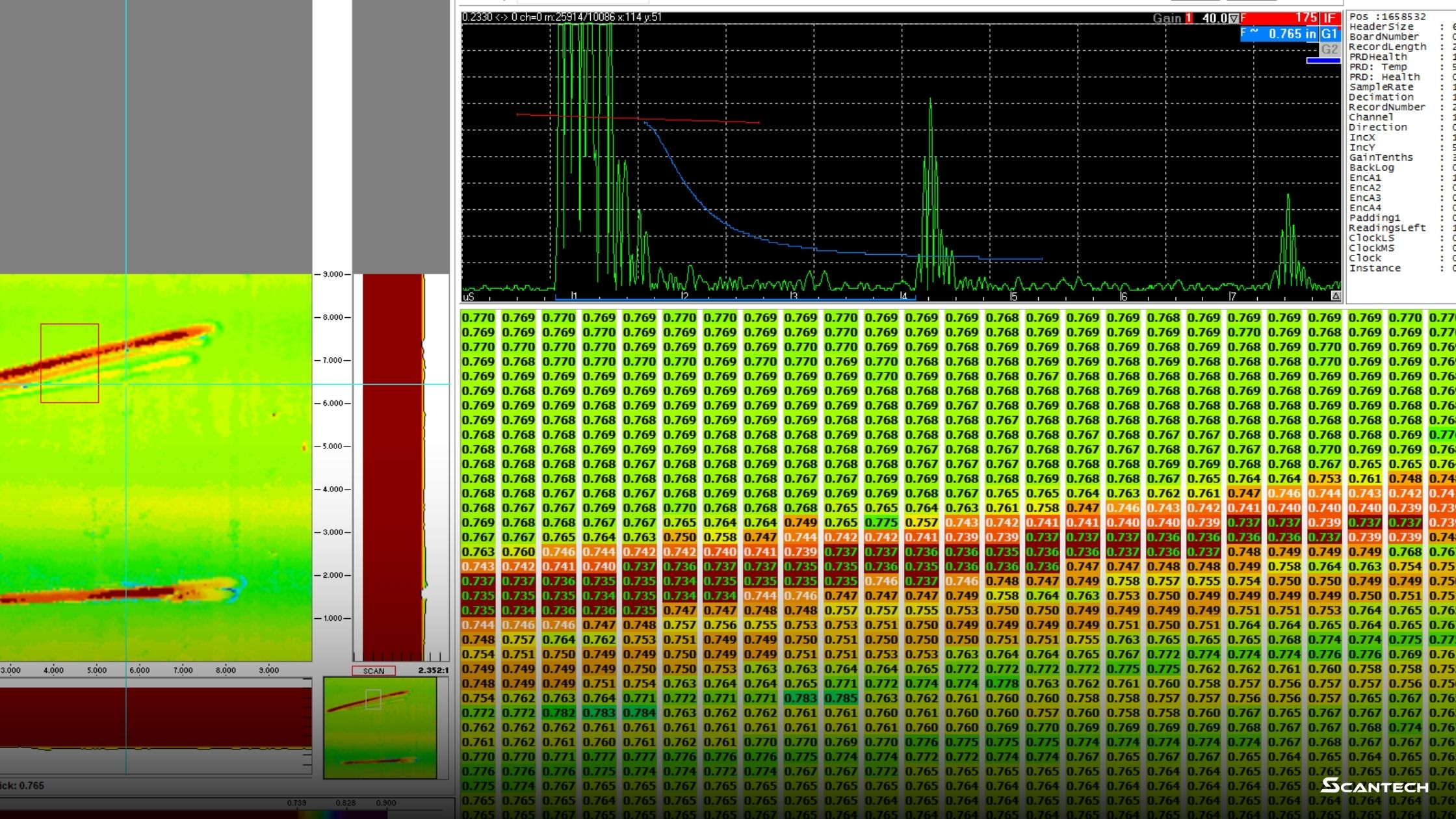

High-resolution ultrasonic instruments, mechanical encoders, and motion-controlled scanners consistently capture complete datasets, leaving fewer blind spots.

For example, comparing manual vs automated UT scanning reveals how automation reduces operator variability and improves repeatability — key factors in reducing rework.

C. Real-Time Data Validation

Inspection software that highlights coverage gaps or signal irregularities in the field allows teams to correct mistakes before demobilization.

Real-time feedback ensures you don’t leave a site wondering if coverage was adequate. It also speeds decision making by confirming data quality immediately.

Learn more about common data failures in NDT at Why Data Quality Still Fails Most Inspections (and How to Fix It).

4. Estimate Templates & Inspection Checklists

Below are tools you can use immediately to standardize planning and reduce rework.

A. Inspection Cost Estimate Template

| Cost Category | Estimated Cost | Notes |

| Technician Labor | $XX/hr | Includes travel and onsite time |

| Equipment Deployment | $ | Depends on hardware needed |

| Access Costs | $ | Scaffolding, permits |

| Downtime Expense | $/hr | Production impact |

| Rework Buffer | % | Contingency for re-scans |

Tip: Use a 0% rework buffer only if your scan validation shows 100% coverage with no signal gaps.

B. Pre-Inspection Quality Checklist

Before you leave the site, confirm:

![]() Surface adequately prepared

Surface adequately prepared

![]() Scan coverage plan entered and confirmed

Scan coverage plan entered and confirmed

![]() Tools calibrated for material and geometry

Tools calibrated for material and geometry

![]() Couplant application consistent

Couplant application consistent

![]() Real-time feedback shows coverage gaps

Real-time feedback shows coverage gaps

![]() Preliminary scans reviewed before demobilization

Preliminary scans reviewed before demobilization

Teams that use this checklist consistently report fewer re-inspections and clearer inspection reports over time.

Treat Data Quality as a Cost-Saver

Reducing re-scans isn’t merely operational efficiency — it’s a strategic advantage.

Better data means:

✔ Higher confidence in decisions

✔ Fewer return visits

✔ Less downtime and logistic cost

✔ Stronger ROI on inspection programs

Inspection strategy isn’t just about completing tasks… it’s about getting full value from every visit. Make data quality your primary cost-savings strategy in 2026.