Table of Contents

Optimizing Data Quality and Inspection Speed for Maintenance Managers & Level III Inspectors

Refinery assets face complex corrosion challenges that demand reliable, high-density UT data. When paired with Analyst XR software, ScanTech’s automated ultrasonic (UT) scanners deliver faster coverage, precise corrosion maps, and real-time reporting—reducing re-scans and rental dependence.

For the complete overview of UT corrosion mapping technology, see our blog: Automated Ultrasonic Scanners for Corrosion Mapping.

Refinery Challenges in Corrosion Mapping

In refineries, corrosion doesn’t just occur uniformly. Localized thinning under insulation, weld seams, and elbows creates critical failure points.

Manual ultrasonic testing captures limited data and can’t scale efficiently during shutdowns. Managers face three main obstacles:

- Inspection speed: Covering large diameters and runs within narrow turnaround windows.

- Data reliability: Variability between technicians or setups causes inconsistent wall-thickness records.

- Traceability: Lack of standardized digital data across teams and shifts.

Automated UT systems address these issues with encoded scanning, software-controlled motion, and integrated digital reporting.

Automation in Action: How Analyst XR Accelerates Coverage

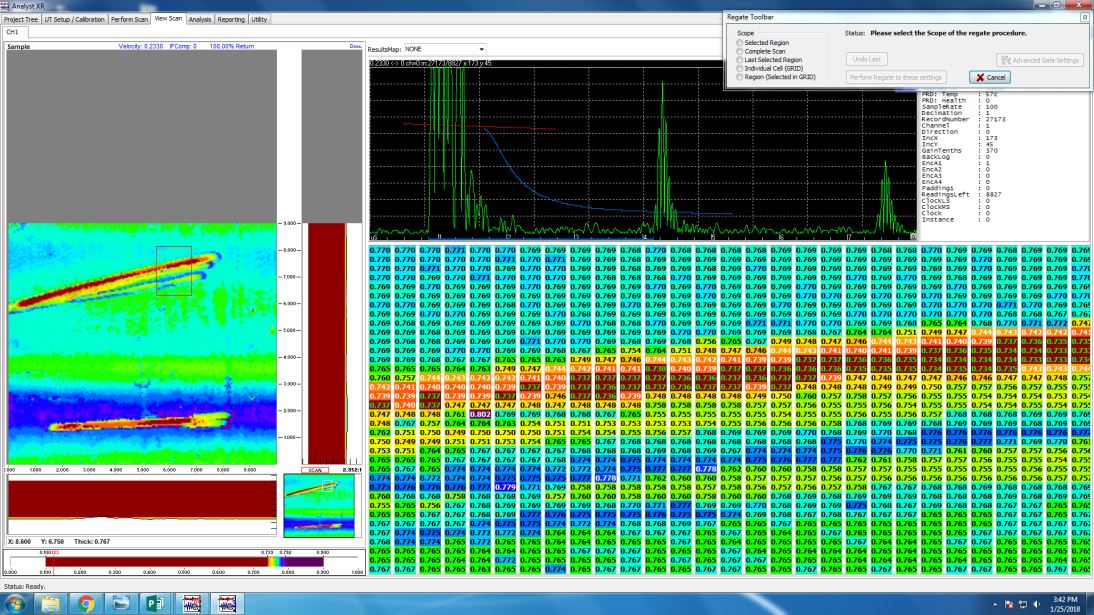

Analyst XR, ScanTech’s corrosion-mapping software, was designed to handle large datasets from automated UT scanners such as the XR Spider.

Together, they form a unified workflow optimized for refinery corrosion monitoring:

- Encoded Automation: The XR Spider scanner maintains raster precision even on large-diameter piping and vessels.

- Real-Time Visualization: Analyst XR renders live corrosion maps so technicians can verify coverage instantly.

- Built-In Algorithms: Includes API 653 and ASME B31G tools for immediate assessment of remaining wall thickness.

- Data Integrity: Automated file tagging ensures each scan segment is traceable and audit-ready.

In one refinery case study, an inspection team completed over 400 square feet of coverage in a single shift—a 40 % reduction in total scan time compared to manual methods.

Best Practices for Pipeline Corrosion Mapping in Refineries

1. Plan Scan Zones Strategically

Identify high-risk areas such as transfer lines, bends, or insulated sections. Automated UT systems can pre-define scan zones in Analyst XR for efficient sequencing.

2. Use Consistent Raster Spacing

Adopt a 10 × 10 mm or smaller grid to ensure data density for API 653 compliance and remaining-life analysis.

3. Maintain Stable Coupling

Use the XR Spider’s constant-force spring system to keep coupling uniform throughout the scan and reduce drop-outs.

4. Validate and Calibrate Regularly

Integrate reference checks into Analyst XR’s workflow before each scan set to maintain accuracy across multiple shifts.

5. Streamline Reporting

Leverage Analyst XR’s automatic report generation to produce API 653 and B31G-ready outputs within minutes of completion.

The Manager’s Perspective: Data Confidence and Scalability

Maintenance managers and Level III inspectors rely on data they can trust. Automation ensures coverage is repeatable, quantifiable, and backed by digital traceability. When Analyst XR is paired with the XR Spider scanner, teams achieve three key advantages:

- Repeatable Accuracy: Automated encoder control minimizes human error.

- Operational Speed: Scans complete 40 % faster than manual methods.

- Cross-Team Alignment: Standardized data formats simplify handover between operators and analysts.

This approach reduces the need for re-scans and streamlines turnaround planning — a topic covered further in our next article, Turnaround Planning: Reducing Re-Scans and Rental Spend with Automated UT.

Cross-Linked Resources

- Read our hub overview: Automated Ultrasonic Scanners for Corrosion Mapping

- Learn more about the XR Spider Corrosion Mapping Scanner

- Explore Analyst XR Software for real-time data visualization and reporting

- See all NDT Scanners

Ready to Map Faster and Smarter?

Automated UT corrosion mapping with Analyst XR delivers the data integrity and inspection speed refineries need to stay ahead of outages and regulations. Explore how your team can implement this workflow and build a more efficient pipeline inspection program today.