Table of Contents

Ever fantasized about peering inside some material without ever having to break it open? Fascinating, right? That fantastic ability is now not just a fantasy, thanks to Phased Array Ultrasonic Testing (PAUT). Being one of the ultrasonic tests, PAUT contributes to precision and versatility in industries concerned with safety and quality. This article will walk you through what you need to know about the basic elements of PAUT, its applications, and why it is rapidly growing as the go-to nondestructive test method for any professional.

Understanding Phased Array Ultrasonic Testing (PAUT): The Basics

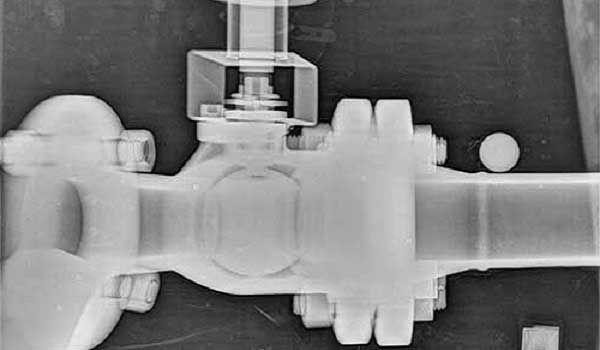

The phased array ultrasonic test method is one of the advanced ultrasonic imaging techniques that detect material defects. Unlike other traditional methods for ultrasonic tests, PAUT uses multiple ultrasonic elements with computer algorithms to create detailed images of the internal structure of test material.

How Does PAUT Work?

- Phased Array of Transducers: PAUT uses a phased array of transducers that can be electronically reoriented. This flexibility enables operators to perform the scanning of large surface areas much faster and more effectively.

- Beam Steering: The methodology implies electronic steering of the ultrasound beam for better orientation. The operation of beam steering becomes crucial when geometries are complex or inaccessible.

- Image Reconstruction: It is complex software that transforms the collected data into highly detailed two-dimensional images—and even sometimes three-dimensional—that a radiologist can study.

Advantages of Phased Array Ultrasonic Testing Over Conventional Methods

These reasons for the fast growth in popularity of Phased Array Ultrasonic Testing (PAUT) are not unfounded. The advantages it has over other UT techniques include the following:

- Speed: Can realize faster data acquisition because one scan can cover a relatively big area.

- Flexibility: It is feasible to carry out difficult inspections in awkward geometries.

- Accuracy: Better detection, characterization, and sizing of defects.

- Data Richness: It provides full data, which can also be stored for further analysis and reference.

Applications of Phased Array Ultrasonic Testing (PAUT)

PAUT technology is used across various industries that require precision and efficiency in their testing processes. Below are some key industries benefitting from this advanced technology:

Aerospace Industry

In such respects, PAUT has become of premier importance within the aerospace industry in aircraft component checks pertaining to integrity. Since safety within this realm is truly instrumental, speed and reliability, in which materials can be checked to surface fatigue cracks or other structural defects, form part of the most important assets.

Oil and Gas Industry

Some of the key applications of PAUT in oil and gas include the testing of pipelines, pressure vessels, and welds to confirm these structures are free from defects and will not lead to catastrophic failure with potential environmental consequences.

Manufacturing

This system is used at the production stage and during quality assurance. PAUT identifies any inconsistency or defects in parts manufactured; hence quality products reach the market.

Stepping into the Shoes of a PAUT Operator

Imagine the feeling of holding such a sophisticated piece of equipment in your hands. A glimpse, now, into one day in the life of the PAUT operator—observe the attentiveness to minute details:

“Every day for a PAUT operator is different. I know that the scans I run could make all of the difference between safety and catastrophe. The tool at my disposal increases not only my efficiency but also allows certain kinds of visions of things, which were completely invisible just a few decades ago.”

Conclusion

As one pulls back the layers that encapsulate Phased Array Ultrasonic Testing (PAUT), it appears that this test methodology is anything but conservative. Encompassing speed, accuracy, and flexibility, it is fast growing as a cornerstone technique in many industries that thrive on continuing to meet the challenges of safety and quality improvement.

The next time one hears of innovations going on in non-destructive testing, remember how PAUT plays its part in making our world a safer place. Interested in how PAUT might help your field, or where the technology will go next? Keep an eye on industry publications and ongoing research to stay updated.