Table of Contents

As industries continue to prioritize safety, efficiency, and compliance, the role of advanced tools in inspections has never been more critical. For aboveground storage tanks (ASTs), adhering to API 653 standards is essential to ensure structural integrity and operational safety. ScanTech’s Analyst software is designed to revolutionize these evaluations, streamlining processes, enhancing precision, and empowering inspectors with powerful tools. Here’s how you can optimize your API 653 tank evaluations with Analyst.

What is an API 653 Inspection?

API 653 inspections are a cornerstone of ensuring the reliability and safety of aboveground storage tanks. These inspections apply specifically to steel, field-erected tanks and cover a comprehensive set of criteria, including:

• Structural Integrity: Examining tank shells, roofs, and floors for wear, corrosion, and other vulnerabilities.

• Compliance and Repairs: Evaluating tanks to ensure they meet API 653 standards for safe operation and providing guidance for necessary repairs or alterations.

• Safety Assurance: Verifying that tanks can safely store materials without risking environmental or operational hazards.

By focusing on maintaining compliance with API 653 standards, these inspections ensure that ASTs continue to meet stringent safety and performance requirements.

How Analyst Software Enhances API 653 Tank Evaluations

ScanTech’s Analyst software introduces advanced capabilities that significantly improve the efficiency and accuracy of API 653 evaluations. Here’s how it makes a difference:

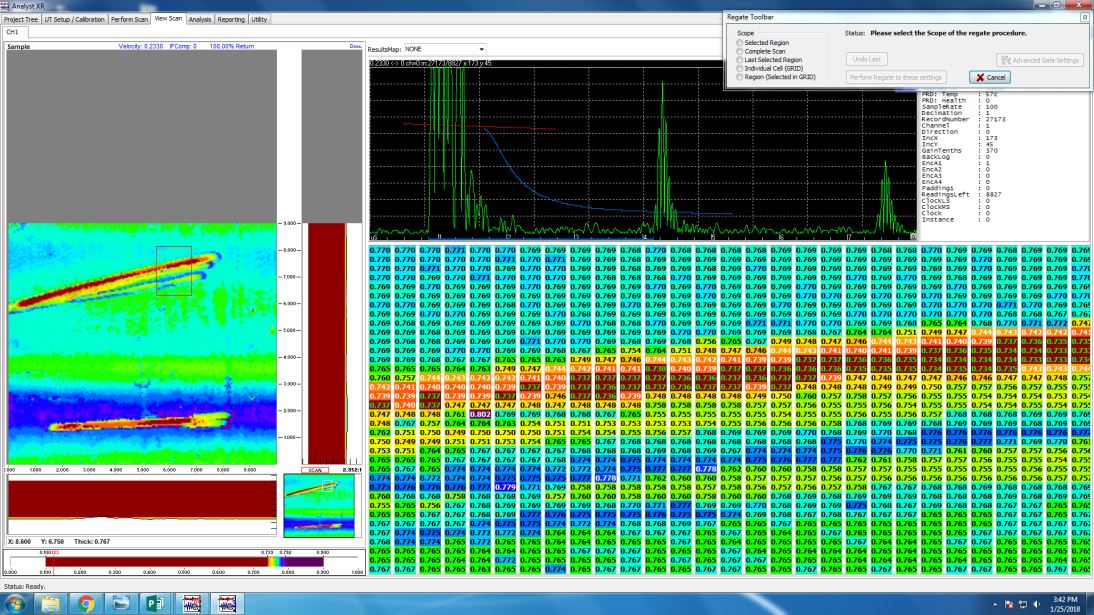

1. Streamlined CML Placement

Condition Monitoring Locations (CMLs) are vital for tracking corrosion and wear. Analyst automates or enables precise manual placement of CMLs on tank shells, roofs, and floors. This information is displayed in a 3D model, offering inspectors a clear and interactive visual representation of the tank’s condition.

2. Comprehensive Settlement Evaluations

Tank settlement can compromise structural integrity. Analyst performs detailed evaluations of shell out-of-plane movement, tank edge settlement, and bottom settlement. These assessments ensure that tanks remain stable and safe under varying conditions.

3. Nozzle and Floor Bulge Assessments

The software includes tools for API 653 nozzle assessments and floor bulge evaluations, visualized in 3D models. These insights enable inspectors to identify and address vulnerabilities that might otherwise go unnoticed.

4. MRT Calculations and Remaining Life Determination

One of the most critical aspects of API 653 inspections is determining Minimum Remaining Thickness (MRT) and remaining tank life. Analyst streamlines these calculations, offering precise data that helps inspectors make informed decisions about repairs or replacements.

What is the Current Version of API 653?

Staying updated with the latest standards is crucial for maintaining compliance. The current version of API 653 incorporates enhancements and updates that reflect advancements in inspection techniques and safety protocols. Using tools like Analyst ensures you’re working within the framework of the most recent API 653 guidelines, positioning your operations at the forefront of industry standards.

Customizing API 653 Inspections with Analyst

One of Analyst’s standout features is its adaptability to different inspection needs. The software provides customizable tools to tailor inspections for specific applications, enhancing usability and precision.

1. Customizable Checklists

Inspectors can create tailored API 653 checklists to address unique inspection requirements. This feature ensures that no critical details are overlooked, regardless of the tank type or condition.

2. 3D Visualization and Reporting

Analyst leverages 3D modeling to present data in a clear and actionable format. Its advanced reporting tools make it easier to share findings with stakeholders, ensuring transparency and facilitating faster decision-making.

3. Integration with API 579 FFS

For a more comprehensive evaluation, Analyst integrates API 579 Fitness-For-Service (FFS) assessments. This feature adds another layer of analysis, providing a full spectrum of data for storage tanks.

How Do I Get API 653 Certification?

Becoming an API 653-certified inspector is essential for professionals responsible for tank inspections and maintenance. The certification process includes:

• Qualifications: Meeting prerequisites in terms of experience and education.

• Study Resources: Preparing with materials and guides tailored to the API 653 examination.

• Examination: Successfully completing the API 653 certification exam.

Having certified inspectors on your team ensures that evaluations are performed with expertise and in compliance with industry standards.

Why Choose Analyst for API 653 Evaluations?

ScanTech’s Analyst software is designed with the needs of inspectors and AST operators in mind. By integrating advanced tools like automated CML placement, MRT calculations, and 3D visualization, Analyst streamlines the API 653 evaluation process. This not only saves time but also enhances the accuracy and reliability of inspections.

Moreover, its customizable features and integration with API 579 make it a versatile tool for diverse applications. With Analyst, you’re equipped to tackle the challenges of maintaining aboveground storage tanks while staying compliant with the latest standards.

Conclusion: Optimize Your API 653 Tank Evaluations with Analyst

API 653 inspections are critical to ensuring the safety, integrity, and compliance of aboveground storage tanks. ScanTech’s Analyst software elevates these evaluations with cutting-edge features, from automated CML placement to detailed settlement assessments and customizable tools.

As industries evolve, having the right tools in your arsenal is essential. Start optimizing your API 653 tank evaluations today with Analyst and experience the future of non-destructive testing.