Table of Contents

When it comes to marine safety, the integrity of a ship’s hull is non-negotiable. With corrosion, cracking, and structural fatigue posing constant risks, ultrasonic testing (UT) remains the gold standard for inspecting hulls. But in today’s world of faster turnarounds and tighter regulations, traditional inspection methods often fall short.

That’s where robotic UT scanners come in.

Built for Harsh Maritime Environments

Manual scanning on vertical hull plates or curved ship surfaces is not only time-consuming—it’s often hazardous. Robotic scanners eliminate this risk by automating the process, delivering consistent probe pressure and scan paths even in challenging geometries. This allows for high-resolution data collection without compromising safety.

Why Accuracy Matters for Ship Inspection

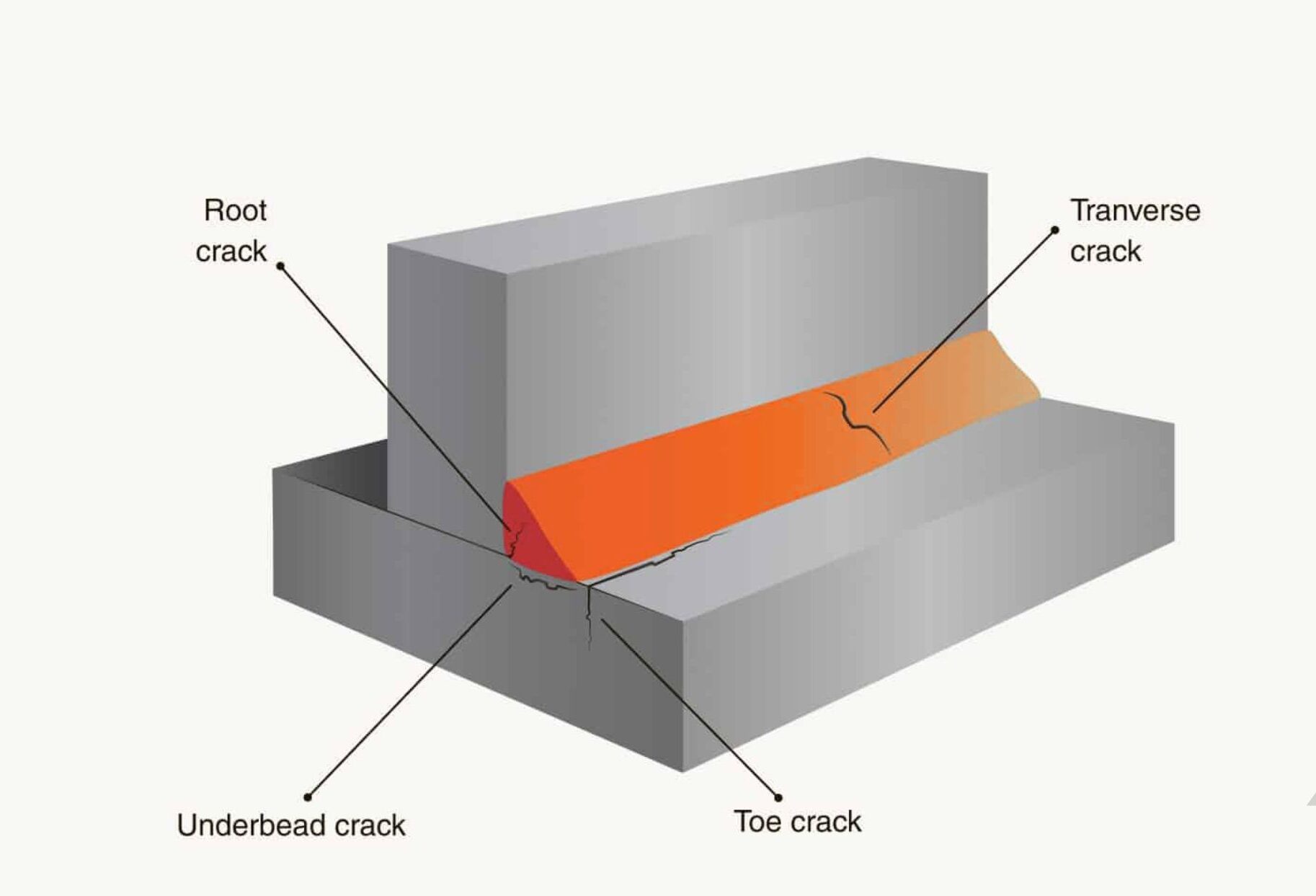

Ships endure extreme environmental conditions. Saltwater, pressure cycles, and constant vibration accelerate material degradation. With robotic UT systems, inspectors can detect early signs of thinning, pitting, and hidden cracking before failure occurs.

By integrating robotic hull inspection into scheduled maintenance routines, fleet operators can:

- Reduce drydock times

- Prevent unplanned outages

- Meet international classification society standards (ABS, DNV, Lloyd’s, etc.)

Real-Time Data, Actionable Results

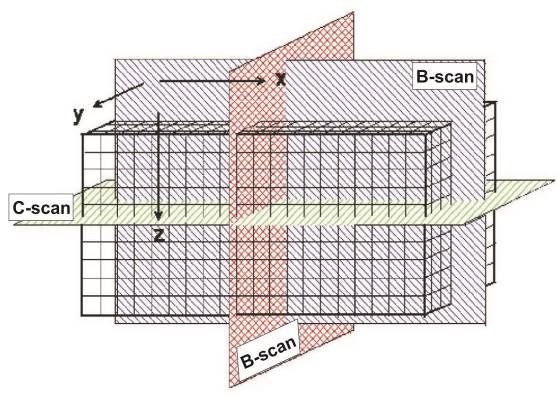

Modern systems allow for real-time B-Scan or C-Scan imaging, helping inspectors pinpoint anomalies faster. Whether inspecting the cargo hold or the outer hull shell, robotic systems simplify documentation and reporting—key for compliance and recordkeeping.

Related Solutions and Tools

If you’re looking to enhance your ship hull inspections, consider reviewing:

Conclusion

Ship hull inspections are critical, but they don’t have to be risky or time-intensive. Robotic UT scanners enable safer, more accurate inspections—reducing downtime and supporting compliance across global fleets.