In Texas—home to some of the largest and busiest refineries in the U.S.—refinery turnarounds (TARs) are mission-critical. These planned shutdowns allow maintenance teams to perform inspections and upgrades that ensure plant safety and compliance.

But when turnaround timelines stretch, the cost of downtime becomes extreme—often millions per day in lost production. To meet those pressures, more facilities are turning to automated NDT (non-destructive testing) to improve efficiency, accuracy, and decision-making during TARs.

The Challenge of Texas Refinery Turnarounds

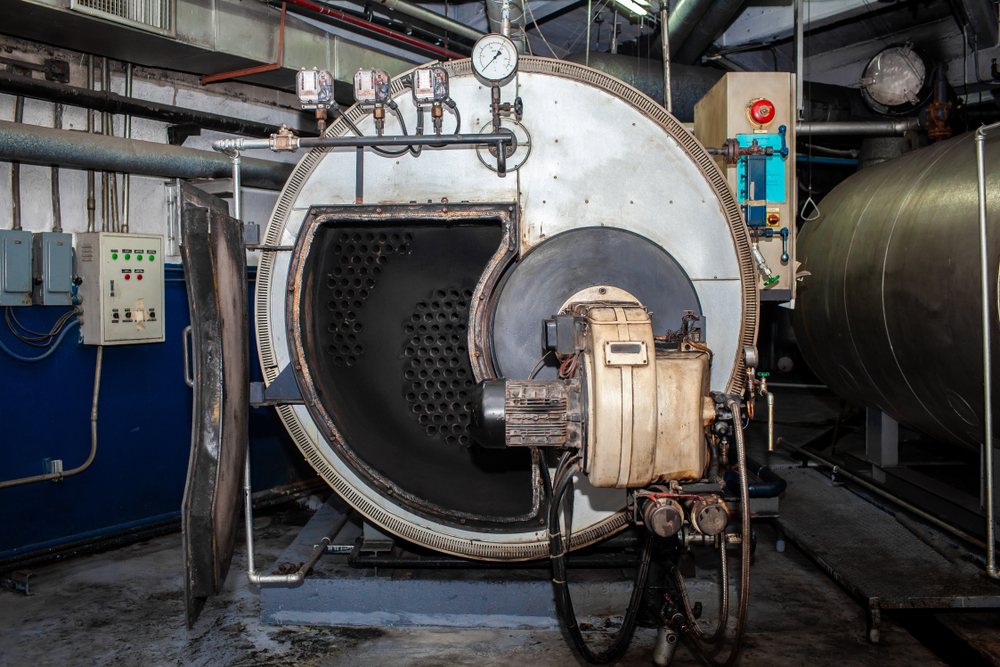

A refinery turnaround is a scheduled plant shutdown for inspection, maintenance, or equipment replacement. These are massive undertakings, especially in the Houston and Gulf Coast region, where much of the U.S. refinery infrastructure is located.

Downtime Is Expensive

Every hour offline represents lost production. That’s why turnarounds must be executed quickly—without sacrificing inspection quality.

The Need for Fast, Accurate Inspection

Manual testing methods slow things down. When refineries rely solely on traditional NDT, they risk delays, rework, and missed defects.

The Role of Automated NDT in Turnaround Inspections

Automated NDT technologies have transformed how inspections are performed during TARs. Instead of relying on manual scans and human interpretation, automated systems deliver faster, high-resolution data with greater consistency.

Traditional Methods = Bottlenecks

Manual ultrasonic testing (UT) is effective—but time-consuming and variable. Each scan depends on the skill and consistency of the technician.

What Automation Adds

- B-Scan Imaging for cross-sectional views of corrosion or material loss

- Corrosion Mapping for large-area visualization of wall thickness

- Real-time analysis that accelerates decisions and repair planning

Key Tools for Automated NDT in Texas Refinery Turnarounds

Here’s how ScanTech’s advanced solutions help cut downtime during TARs:

XR Spider Scanner

This crawler automates large-area corrosion mapping on storage tanks, pressure vessels, and pipelines. Its dual-axis design delivers full-surface scans faster than any manual method.

Analyst XR Software

Built for field efficiency, Analyst XR delivers real-time B-Scan and thickness data to support rapid decision-making—right at the inspection site.

Automated B-Scan Systems

These systems reduce manual steps and human error while producing high-resolution data critical for asset integrity decisions during tight turnaround windows.

Why Texas Refineries Need Smarter Turnaround Strategies

Texas’s refineries—especially along the Houston Ship Channel—are aging. Many are running 24/7 under extreme conditions. That means:

- More frequent corrosion

- More inspection points

- Less margin for error

Efficiency Is the New Standard

Automated NDT helps facilities get more done in less time—without compromising safety or accuracy.

Built for Texas Turnarounds

ScanTech’s automated NDT tools are designed for scale, speed, and repeatability, making them ideal for the aggressive timelines and compliance pressures Texas refineries face.

Less Downtime, More Insight

Refinery turnaround success in Texas depends on speed, precision, and data-driven action. With ScanTech’s automated NDT solutions, you can:

- Cut inspection time

- Improve data quality

- Reduce labor costs

- Make faster, safer decisions

Ready to Take Hours Off Your Turnaround?

If your refinery is facing tight schedules, aging infrastructure, and rising labor costs, now’s the time to upgrade your inspection strategy. Automated NDT systems aren’t just faster—they’re smarter, safer, and proven to reduce downtime. Talk to an NDT Specialist Today!