Why Efficiency Matters in Boiler Tube Inspections

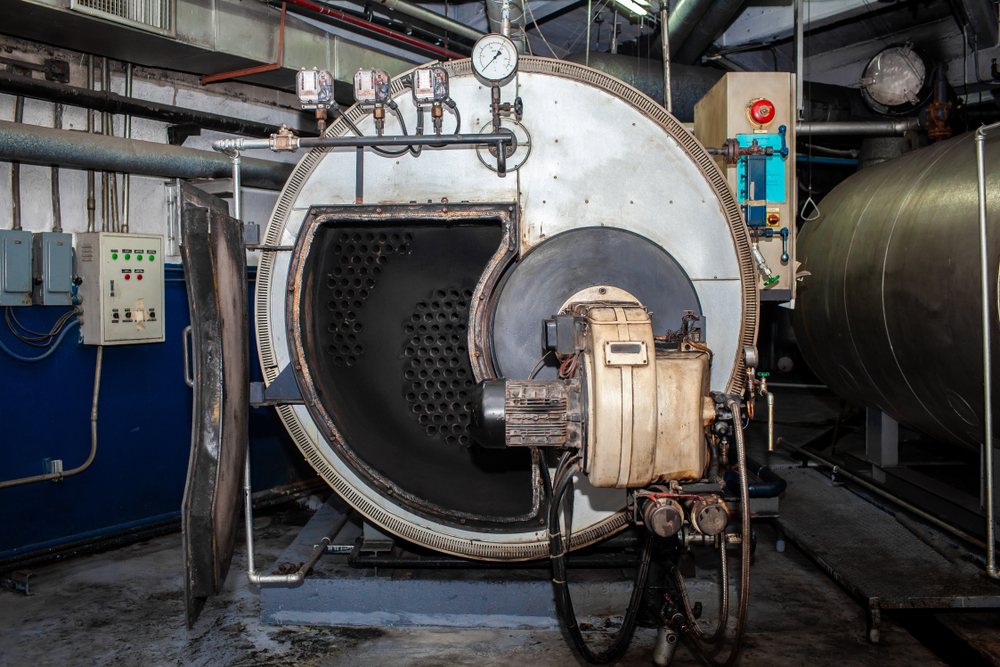

Industrial boilers and fire tube systems are critical to plant operations; but they’re also exposed to harsh conditions that cause corrosion, pitting, and wall thinning over time. Efficient NDT equipment isn’t just a productivity boost; it’s essential for safety, compliance, and preventing costly downtime.

For field technicians, choosing the right tools and methods can drastically cut inspection times while improving the accuracy of results.

Challenges in Fire Tube & Boiler Tube Inspections

- Confined Spaces: Limited maneuverability demands compact, specialized scanners.

- Tight Tube Geometry: Probes must stay aligned without sacrificing coupling quality.

- Varying Access Points: Inspections may require entry from one or both tube ends.

- Surface Prep: Scale, debris, and corrosion can interfere with data quality.

Why Ultrasonic Testing Leads the Way

While radiographic methods have been used historically, ultrasonic testing (UT) provides faster, safer, and more cost-effective results for fire and boiler tube inspections.

Advantages include:

- Immediate Results: Data is available in real-time for quicker decision-making.

- No Radiation Hazards: Eliminates the need for restricted access zones.

- Precision Wall Thickness Data: Essential for API and ASME compliance reporting.

Equipment Features That Improve Efficiency

When selecting NDT equipment for boiler tubes, look for:

- Compact Motorized Scanners: Reduce operator fatigue and increase coverage speed.

- Self-Aligning Probe Holders: Maintain perpendicular contact to tube surfaces.

- High-Torque Drive Systems: Handle fouled or uneven surfaces without slipping.

- Integrated Couplant Systems: Ensure continuous signal quality without manual application.

ScanTech Solutions for Boiler Tube Inspection

ScanTech’s ultrasonic scanners are engineered to thrive in tight-access industrial environments. Features such as our patent-backed tool design and Wheel Pack Assembly ensure optimal probe positioning, even on small-diameter tubes.

Our systems pair with Analyst software for real-time thickness mapping, making inspections faster and more accurate — without sacrificing safety.

Improving boiler tube inspection efficiency comes down to having the right combination of compact, high-precision equipment and user-friendly features. With ScanTech, technicians can complete inspections faster, collect higher-quality data, and keep industrial operations running safely.