Table of Contents

Automation has revolutionized countless industries, and nondestructive testing (NDT) is no exception. In today’s fast-paced world, industrial inspections demand speed, precision, and reliability—qualities that automated scanners deliver. While traditional manual inspections remain valuable, they are often limited in speed and consistency. Automated scanners, on the other hand, enhance these aspects dramatically. By reducing inspection time, providing reliable data, and minimizing human error, automated scanners have become essential for modern inspection routines.

Why Automated Scanners Are Essential in NDT

Automated scanners in NDT solve several major challenges that inspection teams face daily. Here’s how automation makes inspections faster, more accurate, and more consistent than ever.

Increased Efficiency for Faster Inspections

In industrial settings, time is a valuable asset. Inspections are necessary, but they can also cause costly downtime. Automated scanners are designed to speed up inspection times, which is crucial for industries that cannot afford long interruptions. Unlike manual methods, automated scanners can cover more surface area in less time. This efficiency reduces downtime, allowing equipment to return to operation sooner.

For example, consider large storage tanks or extensive pipelines. With manual inspections, scanning these surfaces could take hours or even days. However, automated scanners can systematically cover large areas with even pressure, finishing the job faster. This efficiency frees up personnel to focus on other essential tasks, improving overall productivity.

Enhanced Precision for Accurate Data

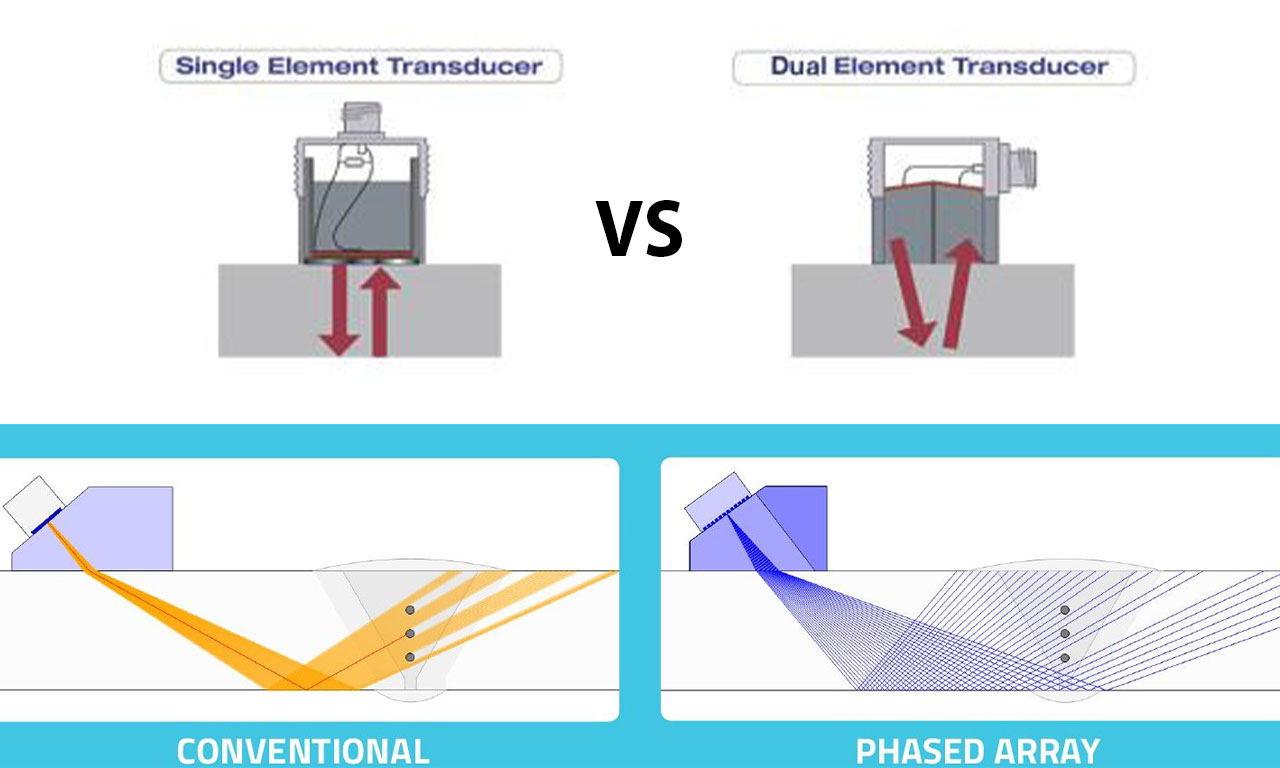

One of the greatest advantages of automated scanners in NDT is their precision. Manual inspections, while effective, can vary due to factors like hand pressure, speed, and angle. These inconsistencies can affect data quality. Automated scanners, however, use controlled pressure and speed, removing variables that often impact data quality in manual inspections. This precision ensures that the collected data is both consistent and highly accurate.

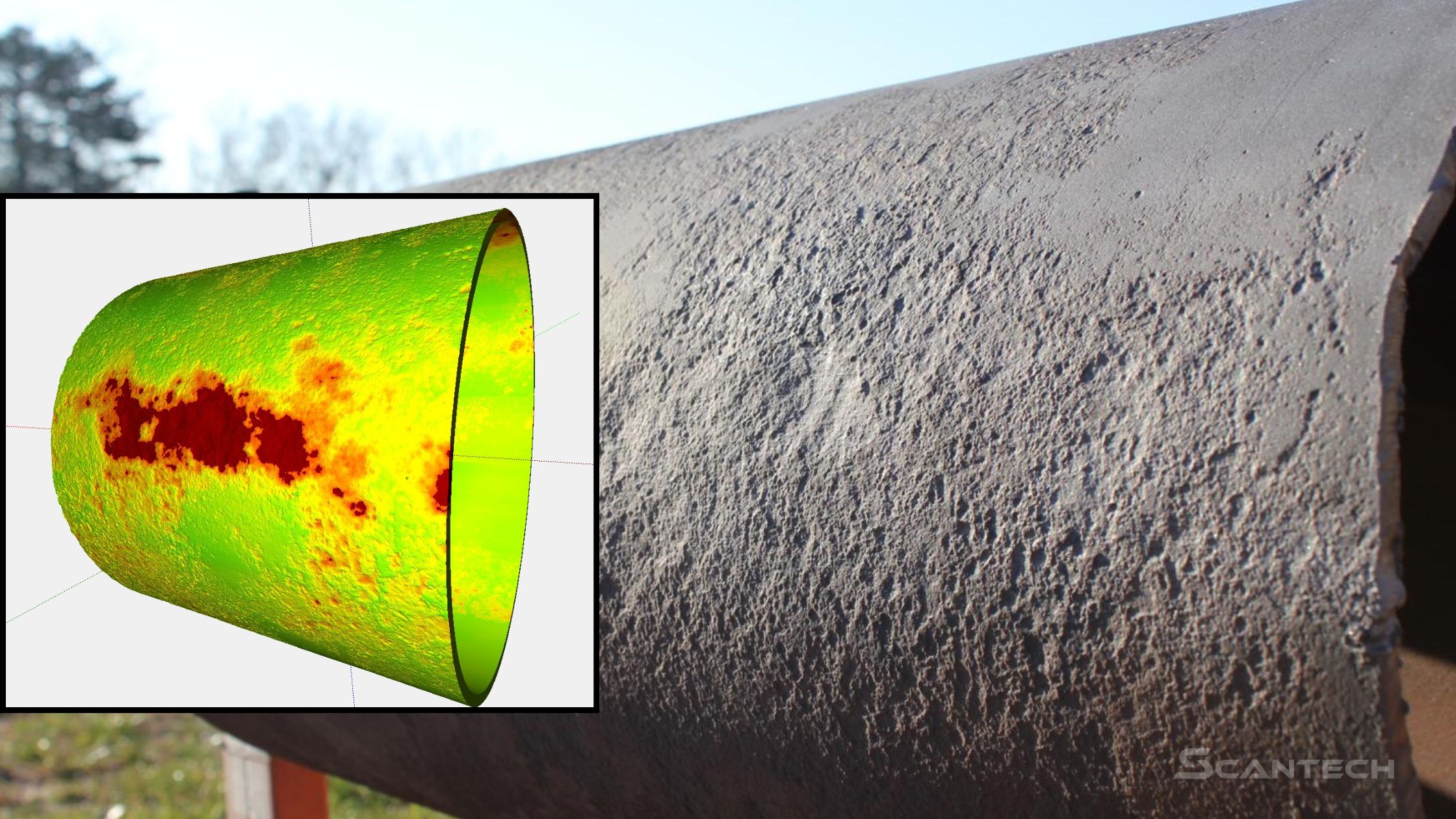

For instance, in ultrasonic corrosion inspections, even small variations in probe contact can affect readings. Automated scanners maintain consistent contact pressure and speed, reducing the risk of data distortion. With automation, inspectors gain a clearer and more reliable picture of a material’s condition. This accuracy is crucial for detecting corrosion and other potential issues.

Reduced Human Error for Reliable Results

Manual inspections depend heavily on the skill and experience of the inspector. However, factors like fatigue, distractions, and technique differences can lead to inconsistencies. Automated scanners reduce these human-dependent variables by using controlled, repeatable scanning parameters. As a result, they minimize human error and provide a more consistent dataset.

Moreover, automated systems store and analyze data digitally, making it easy to track and review over time. Inspectors can quickly access historical data, compare results, and detect trends. This capability supports a more proactive approach to asset maintenance, minimizing the risk of unexpected failures and improving safety.

Featured Automated Scanners in NDT

To achieve the full benefits of automation, it’s essential to choose reliable, high-performing scanners. Here are two of the top scanners that are setting new standards in automated NDT inspections.

XR Spider: Power and Performance

The XR Spider is a highly maneuverable system capable of traversing difficult obstructions made possible by its high suspension compliance. This robust design provides excellent stability and contact, which is essential for high-quality data collection on various surfaces, including those with irregular or corroded areas.

This scanner performs exceptionally well on everything from pipelines to large storage tanks, covering more surface area efficiently and accurately.

X3 Spider: Precision for B Scanning

The X3 Spider is another powerful option, specifically for ultrasonic corrosion inspections. The X3 Spider is ideal for inspections that require sensitive measurements and detailed corrosion mapping. Its powerful yet compact design provides reliability and ease of use, making it a top choice for thorough, accurate inspections.

The Future of NDT Inspections with Automated Scanners

Automated scanners are changing the game in NDT. By increasing efficiency, enhancing precision, and reducing human error, these tools set a new standard for industrial inspections. As industries demand greater safety and reliability, the role of automation in NDT will continue to grow.

Investing in automated solutions like the XR Spider and X3 Spider allows companies to take a proactive approach to asset maintenance. With these tools, they can reduce the likelihood of unexpected failures, improve safety, and enhance operational efficiency. As automation technology continues to advance, automated NDT scanners will become even more capable, reliable, and essential in protecting critical assets.

In the end, automation in NDT is not only about faster inspections. It’s about transforming how industries protect and maintain their most valuable assets. By adopting automated scanners, companies can look forward to faster, safer, and more accurate inspections than ever before. powerful tools can elevate your NDT processes and keep your operations running smoothly.