What is NDT Equipment?

Non-Destructive Testing (NDT) equipment is essential for inspecting materials, components, and structures without causing damage. Used across industries like aerospace, oil & gas, automotive, and manufacturing, NDT equipment helps identify flaws, cracks, corrosion, and material inconsistencies to ensure safety and reliability.

Selecting the right NDT tools depends on the material, defect type, and inspection requirements. In this guide, we’ll explore the different types of NDT equipment, how they work, and key factors to consider when choosing the best solution for your application.

Types of NDT Equipment & Their Applications

NDT methods rely on specialized tools and technologies to detect defects without damaging the test material. Here’s a breakdown of the most common NDT equipment and how they’re used.

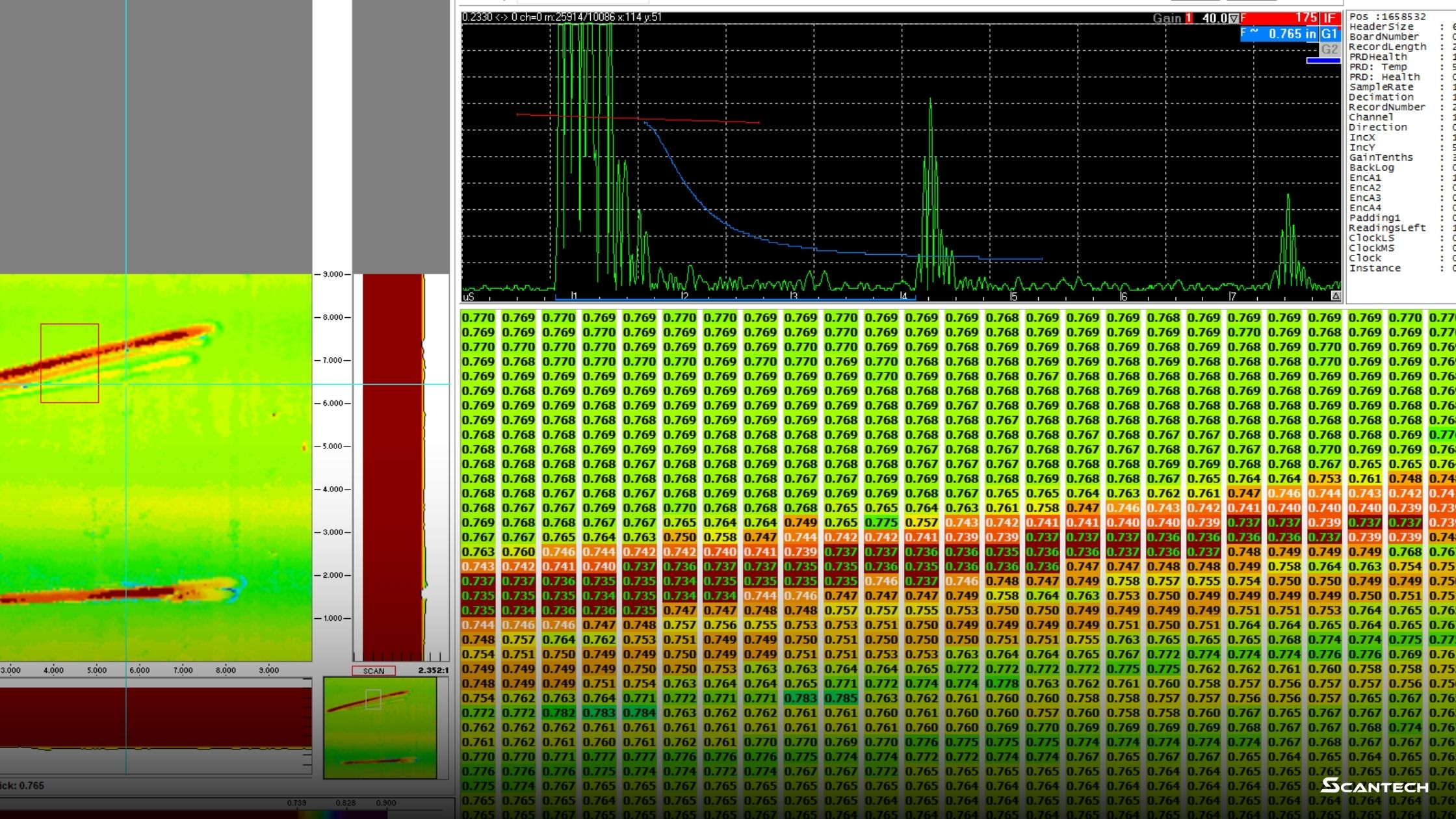

1. Ultrasonic Testing (UT) Equipment

How It Works:

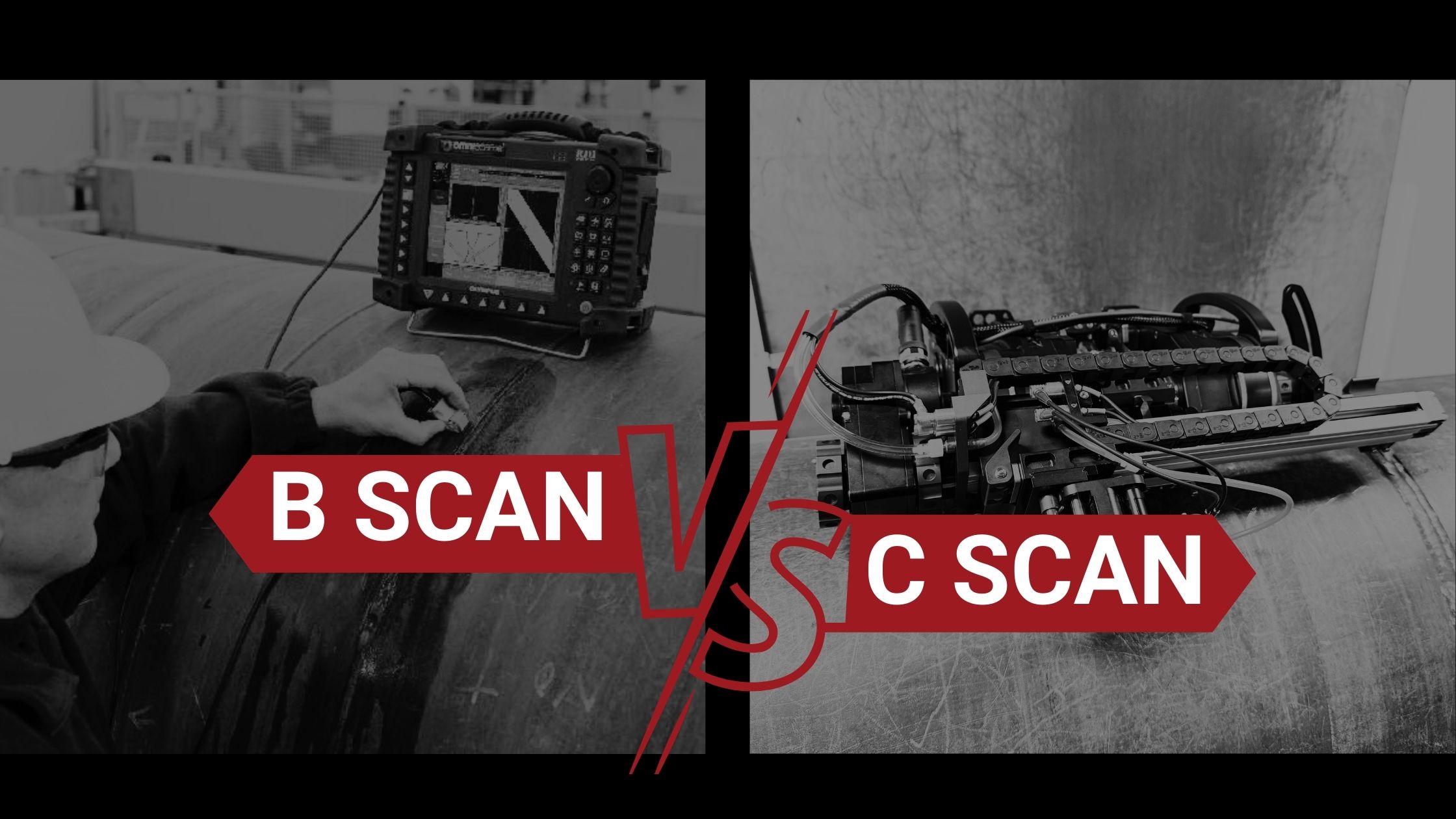

Ultrasonic Testing (UT) uses high-frequency sound waves to detect internal flaws or measure material thickness. A probe transmits sound waves into the material, and any reflections from defects are captured and analyzed.

Best Applications:

✔ Weld inspection

✔ Corrosion detection in pipelines

✔ Aerospace and automotive component testing

Common UT Equipment:

• Ultrasonic flaw detectors – Identify cracks and defects inside materials

• Thickness gauges – Measure material thickness for wear monitoring

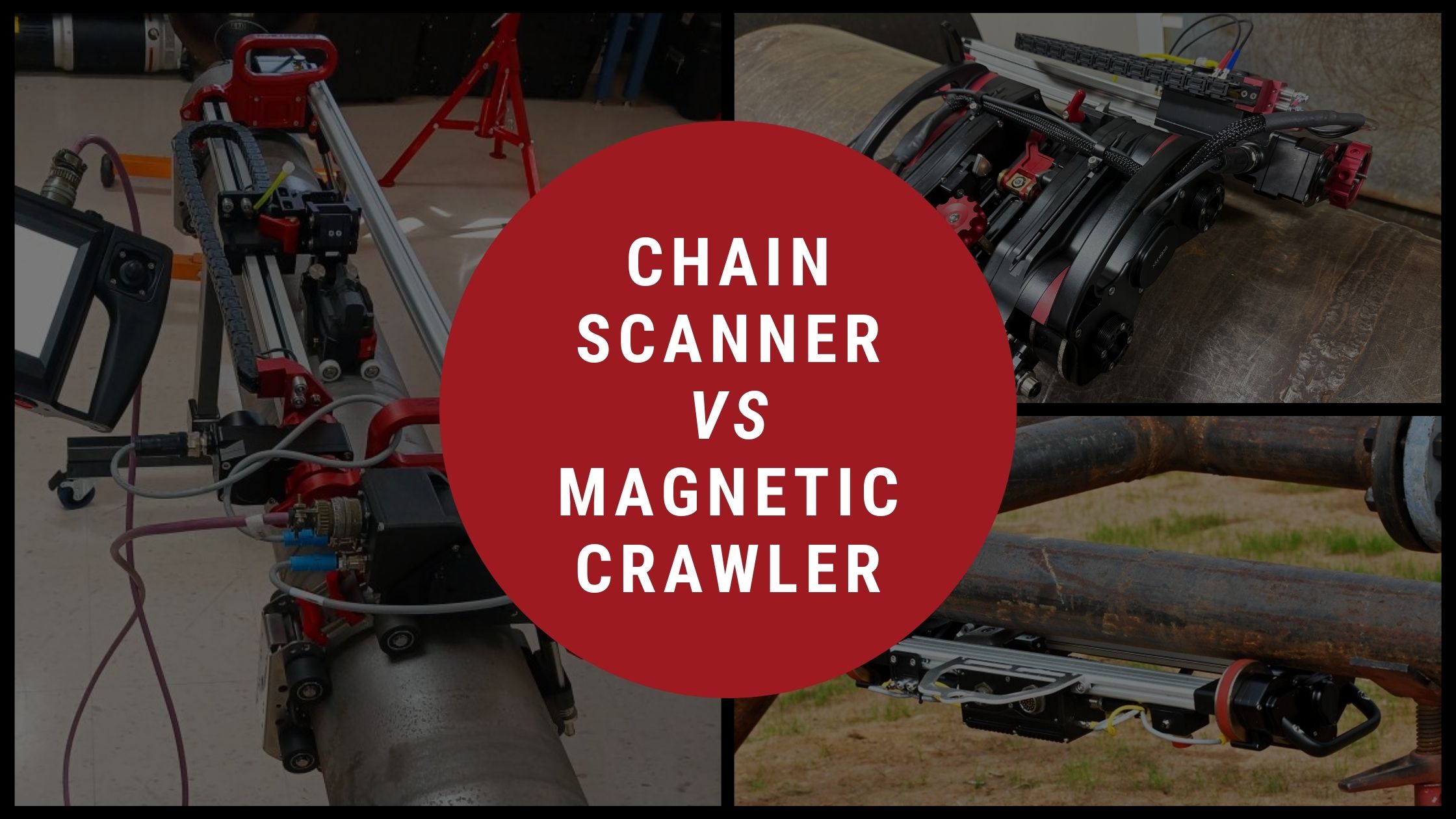

• Phased array UT (PAUT) scanners – Advanced inspection for welds and composites

2. Radiographic Testing (RT) Equipment

How It Works:

Radiographic Testing (RT) uses X-rays or gamma rays to create an image of a material’s internal structure. This method is commonly used in weld inspections and industrial manufacturing.

Best Applications:

✔ Welding and casting inspections

✔ Detecting internal voids and cracks

✔ Aerospace and structural steel testing

Common RT Equipment:

• X-ray machines – Used in industrial and medical radiography

• Gamma ray sources – Provide deep penetration for thick materials

• Digital radiography systems – Modern, high-resolution imaging

3. Magnetic Particle Testing (MT) Equipment

How It Works:

Magnetic Particle Testing (MT) detects surface and near-surface defects in ferromagnetic materials. A magnetic field is applied, and iron particles are used to highlight cracks.

Best Applications:

✔ Weld inspections

✔ Pipeline and automotive testing

✔ Structural steel evaluations

Common MT Equipment:

• Portable magnetic yokes – Used for field inspections

• Bench-mounted magnetic testers – Ideal for production testing

4. Liquid Penetrant Testing (PT) Equipment

How It Works:

Liquid Penetrant Testing (PT) applies a dye solution to the test surface. After a developer is added, defects become visible under UV or white light.

Best Applications:

✔ Detecting surface cracks in metals, plastics, and ceramics

✔ Aerospace and automotive component testing

✔ Weld and cast part inspections

Common PT Equipment:

• Penetrant sprays – Used for field and laboratory testing

• UV inspection lights – Enhance visibility of indications

5. Eddy Current Testing (ET) Equipment

How It Works:

Eddy Current Testing (ET) uses electromagnetic induction to detect surface and near-surface flaws in conductive materials.

Best Applications:

✔ Crack detection in aircraft components

✔ Heat exchanger tube inspections

✔ Electrical conductivity testing

Common ET Equipment:

• Handheld eddy current probes – For small-area inspections

• Automated scanners – Used for large-area testing

How to Choose the Right NDT Equipment

Selecting the right NDT equipment depends on several factors:

1. Material Type

• Ferromagnetic materials? → Use Magnetic Particle Testing (MT)

• Non-ferrous metals? → Use Eddy Current Testing (ET)

• All materials? → Use Ultrasonic Testing (UT) or Radiographic Testing (RT)

2. Type of Defect Being Inspected

| Defect Type | Best NDT Method |

| Surface cracks | PT, MT, ET |

| Internal voids | UT, RT |

| Weld defects | UT, MT, RT |

3. Portability & Ease of Use

• Handheld ultrasonic thickness gauges are ideal for field inspections.

• Bench-top eddy current testers are better for lab testing.

4. Industry Standards & Compliance

Ensure the equipment meets industry regulations, such as:

✔ ASNT (American Society for Nondestructive Testing)

✔ ISO 9712 (International NDT Certification)

Where to Buy High-Quality NDT Equipment

Investing in the right NDT equipment is critical for ensuring accurate inspections.

What to Look for in an NDT Equipment Supplier

✔ Specialized expertise in non-destructive testing

✔ Industry-compliant equipment

✔ Ongoing support & training

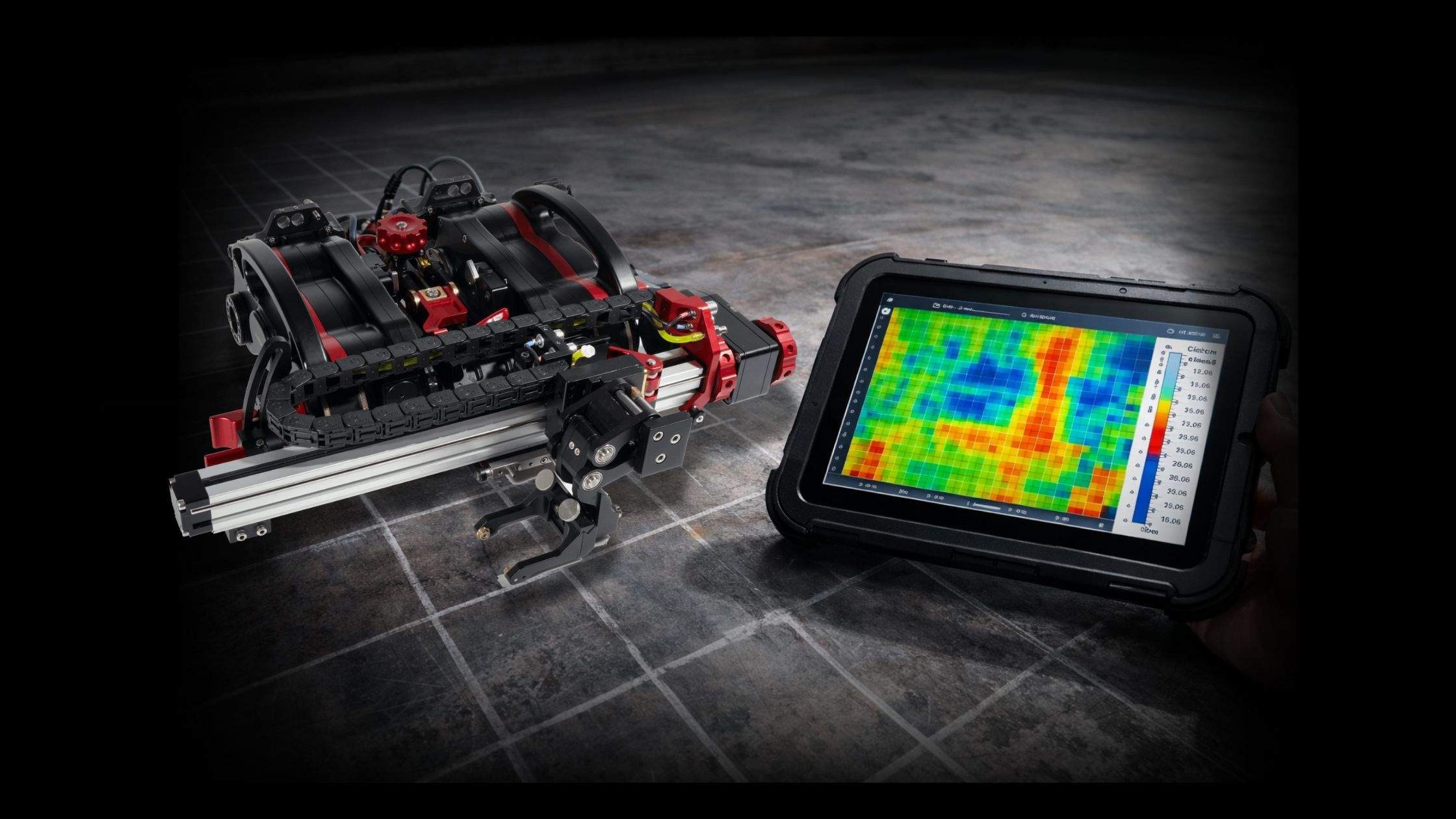

Why Choose ScanTech for Ultrasonic NDT Equipment?

ScanTech specializes in ultrasonic non-destructive testing (UT) equipment, offering:

✔ High-precision ultrasonic flaw detectors

✔ Advanced phased array UT scanners

✔ Expert guidance on selecting the right equipment

Final Thoughts on NDT Equipment

Selecting the right NDT equipment is essential for ensuring safety and quality in industries where failure is not an option. Whether you need to inspect welds, pipelines, or aerospace components, choosing the right method can save time, reduce costs, and improve reliability.

For expert advice on ultrasonic NDT solutions, get in touch with ScanTech today.