Table of Contents

Regular inspections of mud drums and steam drums are critical for maintaining the safety, efficiency, and reliability of industrial boilers. At ScanTech Instruments, we specialize in advanced inspection solutions that help industries stay operational while preventing costly downtime and failures. Let’s explore the importance of these inspections, common failure modes, and how our innovative technologies set us apart.

The Importance of Mud and Steam Drum Inspections

Mud Drums

Mud drums act as the sediment traps for water-tube boilers, where impurities, sludge, and debris accumulate. Failure to maintain and inspect mud drums can result in reduced water circulation and heat transfer, leading to inefficiencies or even catastrophic failures.

Steam Drums

Located at the upper section of the boiler, steam drums are critical for separating steam from water and ensuring system efficiency. Corrosion, cracking, and deposit buildup are significant risks that must be addressed to produce high-quality steam and maintain structural integrity.

Common Failure Modes and Challenges

1.Corrosion and Pitting

• Oxygen corrosion often manifests as pitting in both mud and steam drums. This occurs when oxygen removal from feedwater is incomplete, accelerating the degradation of metal surfaces.

• ScanTech Advantage: Our ultrasonic scanning technology detects corrosion at early stages, ensuring prompt remediation.

2.Thermal Fatigue Cracks

• Steam drum failure is frequently attributed to thermal fatigue. This occurs due to rapid temperature changes during startup and shutdown, causing stress at weld joints, nozzles, and ligaments.

• Our Solution: ScanTech’s high-resolution raster scanning provides precise imaging of cracks and discontinuities, even in complex geometries.

3.Deposit Formation and Scaling

• Deposits of minerals and sludge in mud drums and steam drums impair water flow, reduce heat transfer efficiency, and increase the risk of overheating.

• ScanTech’s Approach: We employ real-time monitoring and ultrasonic techniques to locate and measure deposit thickness, helping you maintain optimal performance.

4.Stress Corrosion Cracking (SCC)

• SCC often occurs due to the presence of corrosive agents in combination with tensile stress. This is particularly prevalent in areas near steam separators and feedwater inlets.

• Proprietary Methods: Our scanners leverage advanced ultrasonic techniques to identify SCC before it compromises system integrity.

Innovative Inspection Techniques

At ScanTech Instruments, we use cutting-edge non-destructive testing (NDT) methods tailored to mud and steam drum inspections:

• Automated Ultrasonic Testing (UT): Our systems provide highly accurate measurements of wall thickness, flaw detection, and internal damage assessment.

• Magnetic Particle Testing (MT): This technique is ideal for detecting cracks in ferromagnetic materials, offering rapid and reliable results.

• Visual and Endoscopic Inspections: We combine traditional visual methods with advanced endoscopic technology to access hard-to-reach areas without dismantling critical components.

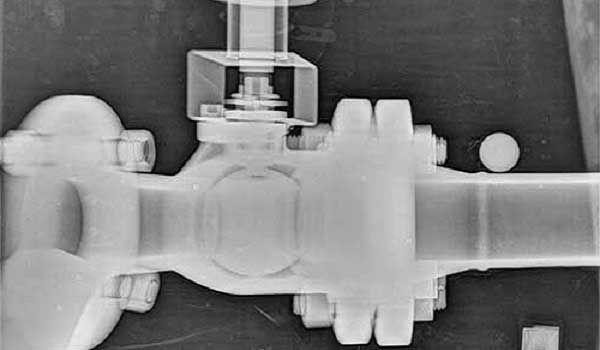

• High-Speed Raster Scanning: Our scanners, including the XR Spider, deliver comprehensive coverage of both flat and curved surfaces with minimal manual intervention.

Applications and Benefits

1.Large Storage Tanks: Conduct ultrasonic corrosion mapping to locate thinning and corrosion hotspots.

2.Piping and Pipelines: Perform axial and circumferential scans to ensure pipeline safety.

3.Ship Hulls: Inspect expansive surfaces for compliance with marine industry standards.

4.Steam Drums: Identify failure-prone areas like welds and ligaments, reducing the risk of unexpected shutdowns.

Key Benefits of ScanTech’s Solutions:

• Early detection of wear, corrosion, and cracks to minimize unplanned downtime.

• Real-time data acquisition for informed decision-making.

• Robust, user-friendly equipment engineered for industrial environments.

Unique Insights from the Industry

From Mat Integrity’s article, we see that understanding steam drum failure modes like fatigue cracking and ligament stress is vital. At ScanTech, we incorporate such insights into our inspection protocols to ensure comprehensive evaluations. For example, our systems are designed to identify signs of ligament cracking or excessive thermal fatigue stress through detailed ultrasonic data analysis. By proactively addressing these risks, we help extend the lifespan of your equipment.

Why Choose ScanTech?

With over 25 years of experience, ScanTech combines innovative technology with field expertise to deliver unparalleled inspection results. Here’s why industries trust us:

• Tailored Solutions: We adapt our services to meet the specific challenges of your operations.

• Advanced Technology: From our robotic scanners to custom-engineered parts, we lead the way in NDT innovation.

• Comprehensive Reporting: Receive actionable insights to optimize maintenance and operational efficiency.

Proactive mud drum and steam drum inspections are essential to ensuring the safety, efficiency, and longevity of your boiler systems. Trust ScanTech Instruments to provide reliable, precise, and innovative solutions that meet the demands of today’s industrial environments. Contact us today to schedule an inspection or learn more about our cutting-edge technologies.