In today’s fast-paced industrial landscape, maintaining safety and efficiency is more critical than ever. Industries such as oil and gas, manufacturing, and construction rely heavily on advanced inspection technologies to ensure the integrity and longevity of their infrastructure. ScanTech Instruments, a leader in ultrasonic testing technology, is at the forefront of this revolution, offering cutting-edge solutions that are transforming the way inspections are conducted.

Industries face numerous challenges in ensuring the safety and efficiency of their operations. Traditional inspection methods often fall short in providing the accuracy and reliability required to detect potential issues before they become critical. This is where ultrasonic testing comes into play.

Ultrasonic testing is a non-invasive method that uses high-frequency sound waves to detect flaws and measure material thickness. Its advantages over traditional methods include higher precision, the ability to inspect complex geometries, and faster results. These benefits make ultrasonic testing an essential tool across various sectors, from pipeline inspection in the oil and gas industry to corrosion mapping in industrial tanks.

Since its inception, ScanTech Instruments has been committed to pushing the boundaries of ultrasonic automation technology. With over 20 years of experience, ScanTech has introduced several groundbreaking innovations that have set new standards in the industry.

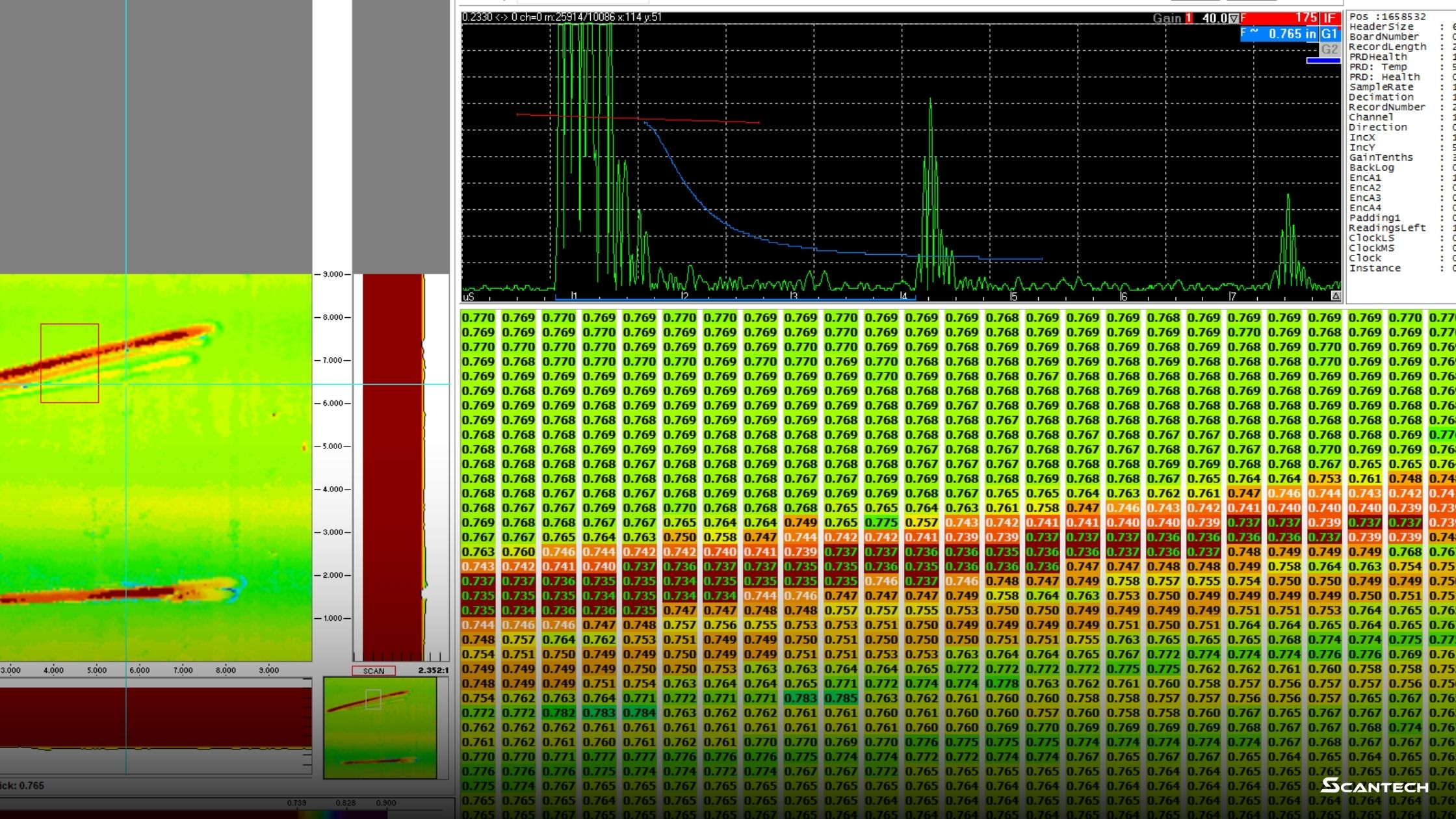

One of ScanTech’s most notable contributions is the development of highly maneuverable scanners, such as the Vertex Scanner, designed to navigate complex structures and deliver accurate data even in challenging environments. Additionally, ScanTech’s software solutions, like the Analyst XR, offer real-time data analysis and reporting, further enhancing the efficiency and reliability of the inspection process.

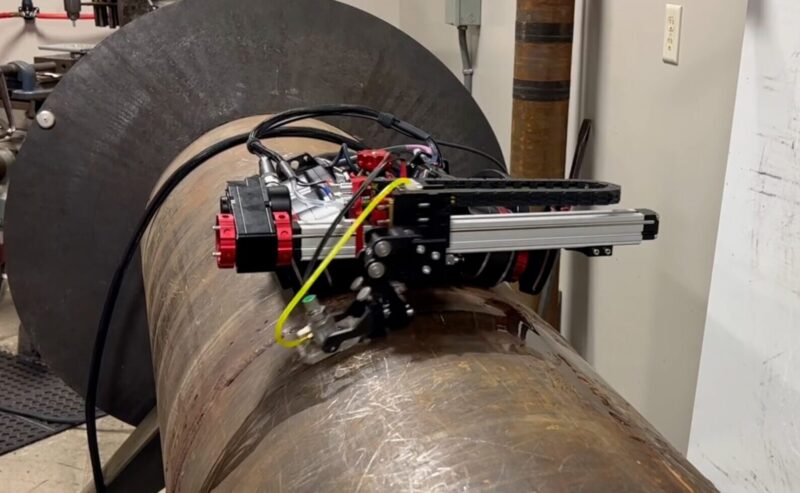

The Vertex Scanner exemplifies the advantages of modular design with its innovative features:

The Vertex Scanner is equipped with toolless modules, making it incredibly easy to switch between different inspection setups. Whether you need a front raster arm, a side raster arm, or multi-probe weld scans, the Vertex Scanner allows for quick and hassle-free adjustments.

Designed to scan circumferentially on carbon steel using magnetic wheels or non-ferrous materials with a chain attachment system, the Vertex Scanner is versatile enough to handle various materials and inspection scenarios. This adaptability makes it suitable for a wide range of applications, from pipeline inspections to structural assessments.

The Vertex Scanner is compatible with ScanTech’s powerful Analyst Controller and software, as well as third-party phased array systems. This integration ensures that users can leverage advanced data acquisition and analysis features, enhancing overall inspection efficiency.

Constructed with rugged components, the Vertex Scanner is built to withstand the demanding conditions of industrial environments. Its field-proven straight-line probe lift provides greater ruggedness and positional accuracy, ensuring reliable performance in real-world applications.

The Vertex Scanner’s modularity and versatility have made it an invaluable tool in various industries. Here are some real-world applications where the Vertex Scanner has significantly enhanced inspection efficiency:

In the oil and gas sector, pipeline integrity is paramount. The Vertex Scanner’s ability to perform circumferential and longitudinal scans on pipelines ensures comprehensive inspections. Its magnetic wheels provide secure attachment to carbon steel pipelines, while the chain attachment system is perfect for inspecting non-ferrous materials.

For power plants, regular inspection of critical components like boilers and turbines is essential. The Vertex Scanner’s modular design allows for quick adaptation to different inspection tasks, ensuring thorough and efficient evaluations. Its compatibility with phased array systems enhances the detection of potential issues before they lead to costly failures.

The Vertex Scanner is also widely used in manufacturing and construction for inspecting structural components. Its ability to switch between various probe configurations and its rugged design make it ideal for these demanding environments. The scanner’s precise measurements and real-time data analysis help maintain structural integrity and safety.

The modular design of the Vertex Scanner not only provides flexibility and adaptability but also significantly enhances inspection efficiency. Here’s how:

With toolless module attachments, the Vertex Scanner allows for quick changes between different inspection setups. This reduces downtime between tasks, enabling continuous operation and increasing overall productivity.

The ability to customize the scanner for specific tasks ensures that inspections are performed with the highest accuracy. Whether it’s a complex weld inspection or a straightforward pipeline scan, the Vertex Scanner’s modular components ensure optimal performance.

By using a single scanner for multiple tasks, companies can save on the cost of purchasing and maintaining multiple devices. The Vertex Scanner’s modularity allows for component reuse, reducing the need for additional equipment and lowering overall expenses.

The Vertex Scanner from ScanTech Instruments demonstrates how modularity can enhance inspection efficiency. Its versatile features, combined with real-world adaptability, make it an essential tool for various industries. By reducing downtime, improving accuracy, and offering cost savings, the Vertex Scanner sets a new standard in ultrasonic inspection technology.

Ready to enhance your inspection efficiency with the Vertex Scanner? Discover the full capabilities of this innovative solution by visiting our product page or contacting us for a consultation.

CLIX redefines NDT with unmatched precision, versatility, and ease of use — designed to streamline inspections and maximize uptime.