In industries where safety, reliability, and efficiency are paramount, corrosion is a silent threat. Over time, it can compromise the integrity of critical infrastructure, leading to costly repairs or even catastrophic failures. Enter the corrosion mapping scanner—an essential tool that empowers industries to detect, assess, and manage corrosion effectively.

What Is a Corrosion Mapping Scanner?

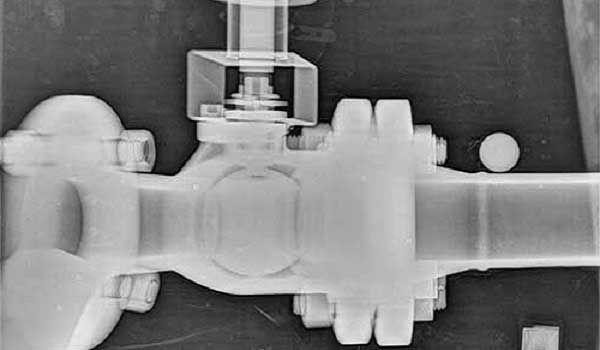

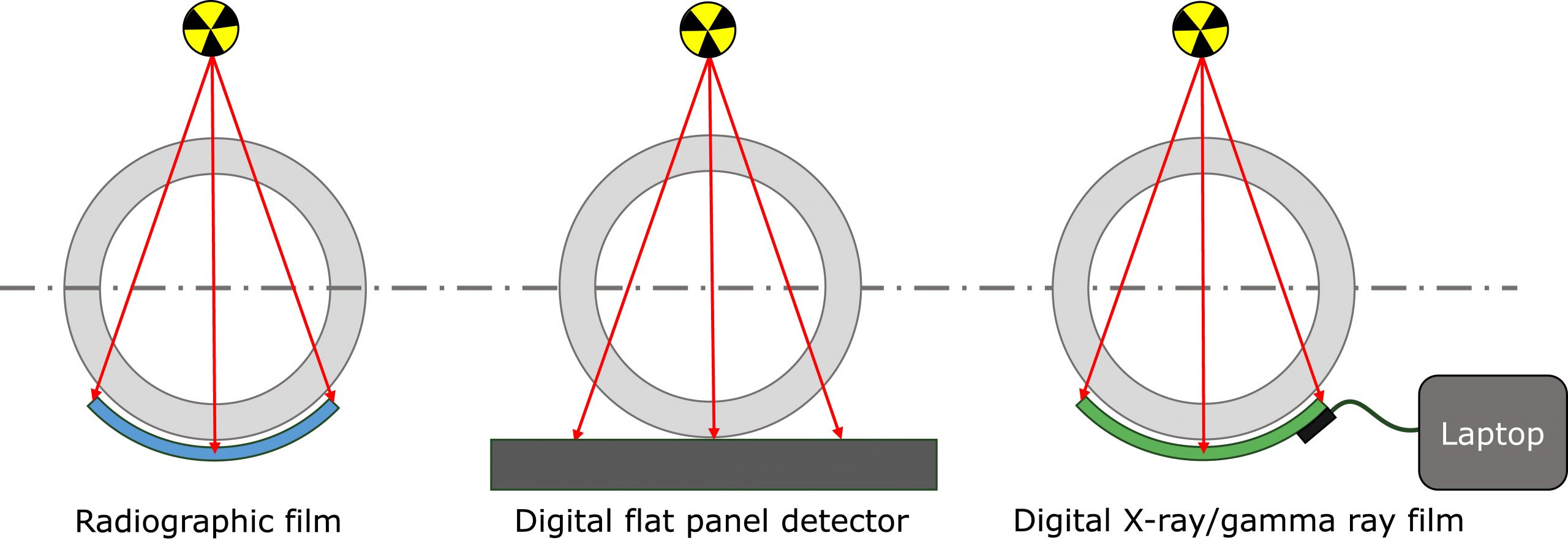

A corrosion mapping scanner is an advanced non-destructive testing (NDT) system designed to provide precise and detailed imaging of corrosion in various materials. This tool is vital for inspecting pipelines, storage tanks, pressure vessels, and other critical components. By delivering high-resolution data, it enables engineers and maintenance teams to identify problem areas before they escalate, ensuring operational safety and extending the lifespan of assets.

Benefits of Using a Corrosion Mapping Scanner

- Accurate Data Collection: A corrosion mapping scanner delivers detailed visualizations of material thickness and corrosion patterns, enabling precise assessments.

- Cost Savings: Early detection of corrosion reduces downtime and eliminates the need for costly emergency repairs.

- Enhanced Safety: Identifying weak points in structures minimizes the risk of failures and ensures a safe working environment.

- Comprehensive Coverage: Modern scanners can navigate complex geometries, providing complete inspection coverage.

- Customizable Solutions: Many corrosion mapping scanners, like those from ScanTech Instruments, are modular and adaptable to meet the specific needs of various industries.

Key Features to Look for in a Corrosion Mapping Scanner

When selecting a corrosion mapping scanner, it’s essential to consider features that align with your inspection requirements:

- High-Resolution Imaging: Ensure the scanner provides accurate and detailed corrosion data.

- Modularity and Portability: A lightweight, modular design allows for easier transportation and versatility in various applications.

- Durability: The scanner should withstand harsh industrial environments.

- Ease of Use: User-friendly interfaces and software streamline the inspection process, saving time and resources.

Applications of Corrosion Mapping Scanners

Corrosion mapping scanners play a vital role across industries, including:

- Oil and Gas: Inspecting pipelines and storage tanks to ensure operational safety.

- Power Generation: Monitoring the condition of boilers, turbines, and other critical components.

- Chemical Processing: Assessing corrosion in pressure vessels and reactors.

- Pulp and Paper: Detecting wear in dryer rolls and other machinery exposed to high humidity.

- Marine and Offshore: Ensuring the integrity of ship hulls, offshore platforms, and subsea structures.

Why Choose ScanTech Instruments for Corrosion Mapping?

At ScanTech Instruments, we specialize in designing and manufacturing cutting-edge corrosion mapping scanners tailored to real-world industrial challenges. Our scanners deliver unparalleled accuracy, durability, and ease of use, backed by our commitment to innovation and customer service. Manufactured in the USA, our systems are built with the inspector in mind, combining robust hardware with intuitive Analyst software for seamless inspections.

The Future of Corrosion Mapping

As technology advances, the capabilities of corrosion mapping scanners continue to expand. From enhanced automation to real-time data processing, these tools are evolving to meet the increasing demands of industrial inspection. At ScanTech Instruments, we remain at the forefront of these developments, ensuring our solutions empower industries to stay ahead of corrosion challenges.

Ready to Transform Your Inspection Process?

Invest in a corrosion mapping scanner today and take the first step toward safer, more efficient operations. Visit our website to learn more about our innovative solutions and how they can benefit your industry.