Chain Scanner vs Magnetic Crawler

Chain scanners and magnetic crawlers both automate inspection movement, but they solve different problems. The decision usually comes down to three things: attachment, material (ferrous vs non-ferrous), and payload (how much method hardware needs to ride on the platform).

For broader context on automated pipe workflows, see pipe inspection solutions.

Quick comparison

| Category | Chain Scanner | Magnetic Crawler |

| Best surface | Pipes/tubes (wrap-around) | Flat or curved ferrous surfaces |

| Material compatibility | Ferrous + non-ferrous (depends on design) | Ferrous only (needs magnetic attraction) |

| Attachment method | Chain tension / wrap | Magnetic wheels/tracks |

| Typical use cases | Long pipe runs, mixed materials, limited magnetic surfaces | Steel assets where magnet traction is reliable |

| Risk factors | Chain fit, alignment, surface obstacles | Magnet traction loss (coatings, curvature, debris) |

| Payload flexibility | Often high (varies by model) | Moderate to high (varies by model), limited by traction |

What is a chain scanner?

A chain scanner wraps around a pipe using links or a band system. It drives along the pipe length while staying aligned around the circumference. Chain scanning is commonly used when:

- The pipe is non-ferrous (stainless and many corrosion-resistant alloys)

- The inspection needs long travel distances

- Wrap-around stability is preferred over surface adhesion

What is a magnetic crawler?

A magnetic crawler uses magnetic traction (wheels or tracks) to move along ferrous surfaces. It tends to work best when:

- The surface is carbon steel or otherwise magnetic

- Coatings and surface condition still allow reliable traction

- The path includes vertical or inverted travel where holding force matters

Ferrous vs non-ferrous: the fastest filter

Ferrous assets (carbon steel, many low-alloy steels)

- Chain scanner: strong on pipes when wrap stays stable.

- Magnetic crawler: strong when magnetic traction stays consistent.

Non-ferrous assets (stainless and many corrosion-resistant alloys)

- Chain scanner: usually the practical choice because it doesn’t rely on magnetism.

- Magnetic crawler: usually not viable because adhesion is the limiter.

Best-fit rule: if non-ferrous compatibility is required, chain scanning is typically the first filter.

Payload and method compatibility

Payload matters because different inspection methods require different add-ons: probe holders, encoders, couplant delivery, radiography holders, cable management, and so on.

Method compatibility (high-level):

- Conventional UT: both platform types can support it, depending on probe mounting and couplant strategy

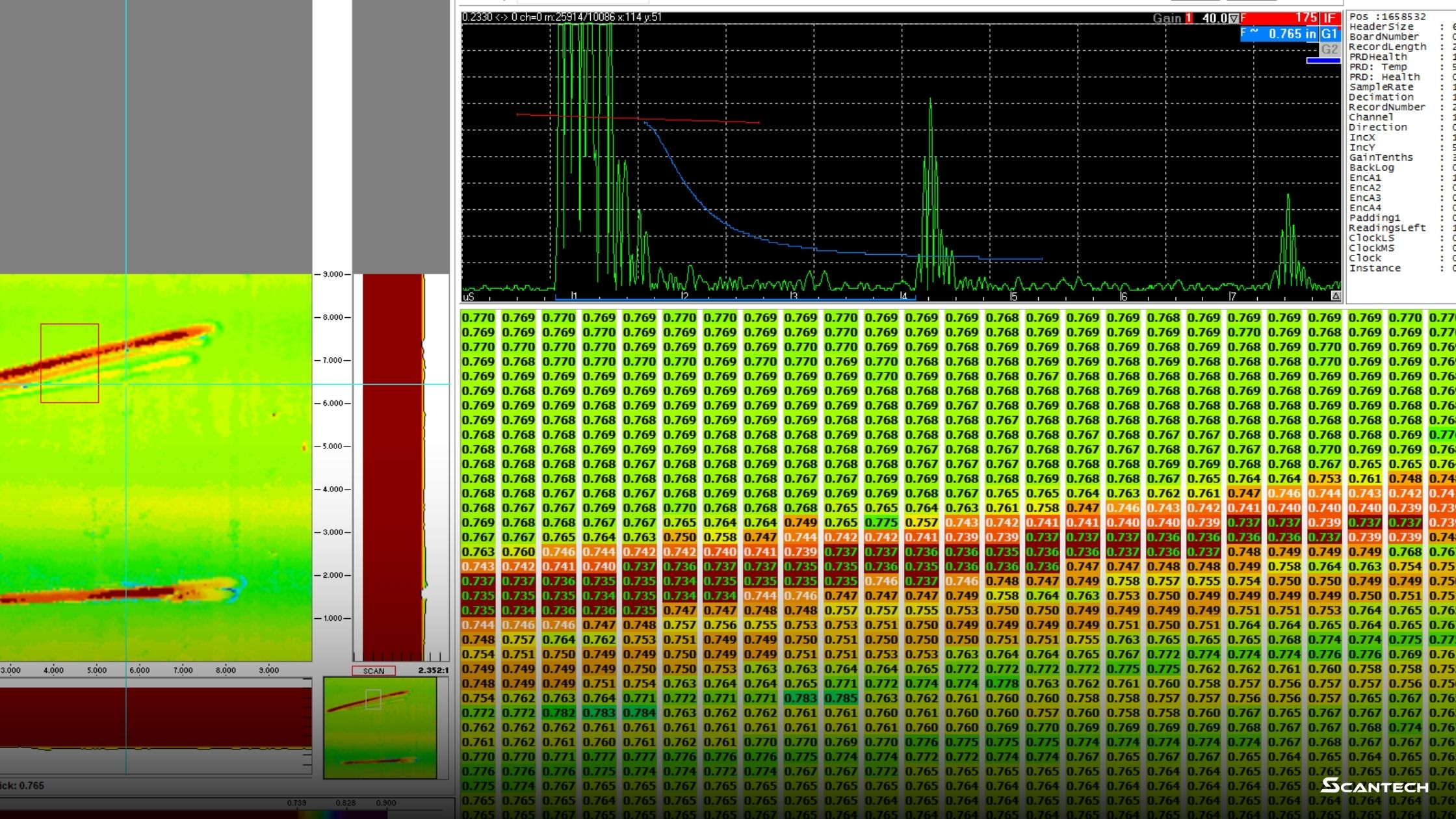

- Corrosion mapping (C-scan): stability and repeatable raster mechanics matter more than attachment style alone

- Weld inspection workflows: access, geometry, and consistent coupling usually drive the decision

- Radiography (DR/RT tooling): payload capacity and repeatable movement become central

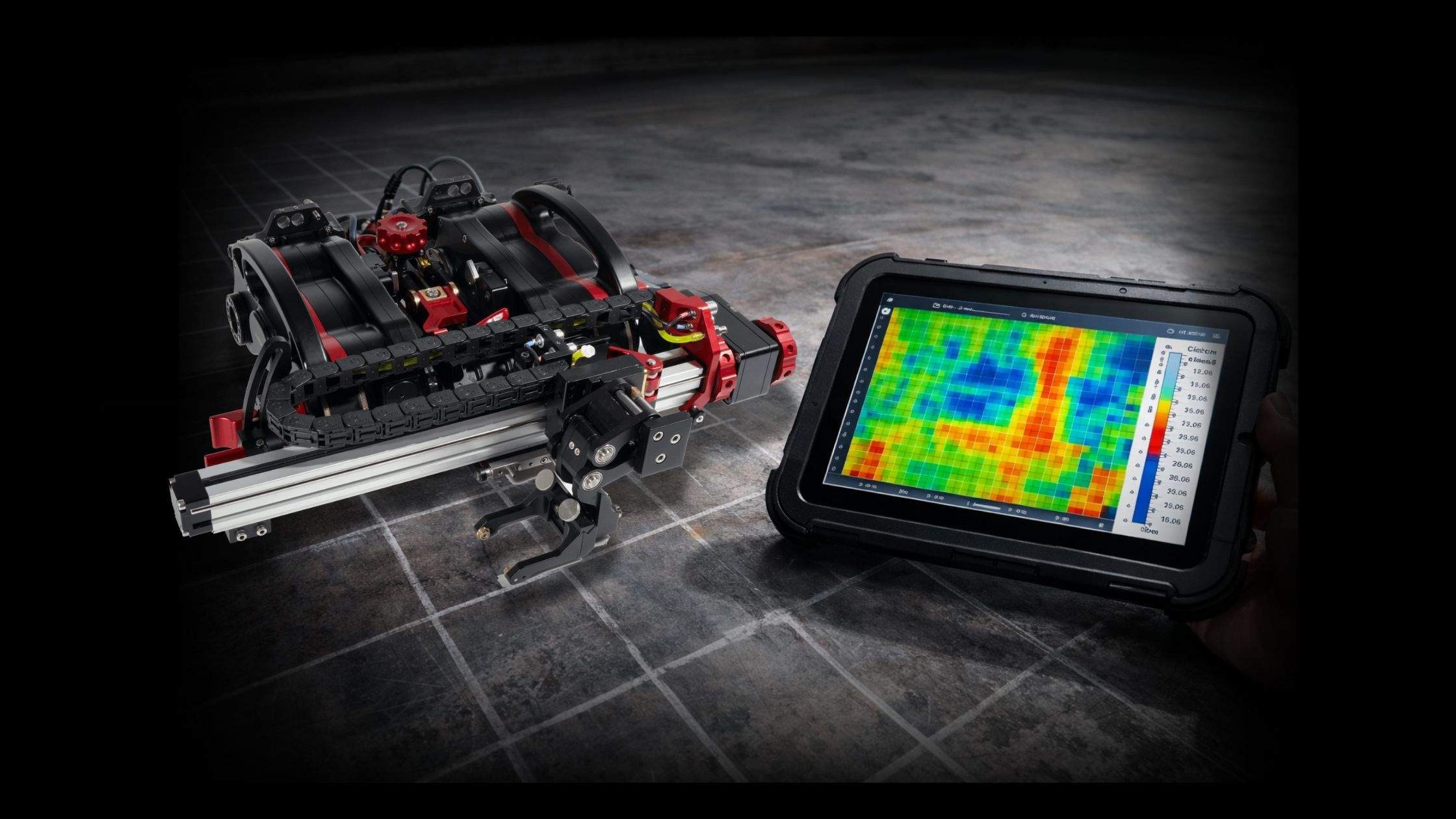

For modular inspection setups across varying jobs, a reconfigurable platform can simplify planning. The Apex modular scanner platform is one example of a system designed around reconfiguration and multiple use cases.

Practical differences that change performance

1) Surface condition and coatings

Magnetic crawlers can lose traction with certain coatings, debris, or geometry transitions. Chain scanners are usually less sensitive to coatings, but obstructions can interfere with wrap stability.

(2) Geometry and access

Chain scanners shine on pipe runs where wrap-around is straightforward. Magnetic crawlers tend to perform well on ferrous surfaces where wrap is impractical and traction is predictable.

(3) Setup speed vs repeatability

Chain scanning depends on correct sizing and stable tension. Magnetic crawling depends on traction verification and safety margins, especially on vertical or overhead surfaces.

How to choose: a simple decision guide

Choose a chain scanner when:

- Non-ferrous compatibility is required

- Wrap-around stability on pipe is the priority

- Long travel distance on pipe is the main need

Choose a magnetic crawler when:

- The asset is reliably ferrous and traction is dependable

- The path includes climbing or inverted travel

- Wrap-around is impractical due to geometry or access

If the primary objective is weld-focused workflows, see weld inspection solutions.

FAQs

Can a magnetic crawler inspect stainless steel?

Is a chain scanner only for pipes?

Which is better for long inspection distances?

Which supports heavier payloads?

Key takeaway

Chain scanners are typically the better fit when non-ferrous compatibility and wrap-around stability on pipe are priorities. Magnetic crawlers are typically the better fit when the surface is reliably ferrous and magnetic traction can be counted on.

Book a demo using the form on this page to review inspection requirements and best-fit options, or contact ScanTech for routing and general questions.