Best Automated UT Setup for API 653 Tank Inspections

Automated ultrasonic (UT) scanning systems provide consistent thickness data, reliable position encoding, and efficient coverage for tank wall assessments. This guide outlines how automated scanning supports code-compliant inspections and what to look for when selecting hardware and workflows.

Understanding API 653 Inspection Requirements

API 653 requires documented inspection of storage tanks, including thickness measurements and condition assessments for shell, bottom and roof components. Inspection planning, frequency, and reporting must be based on measured corrosion rates, remaining-life calculations, and qualified inspector judgement — inspection intervals are not fixed but are determined using API 653 methods and risk-based considerations.

Key points:

-

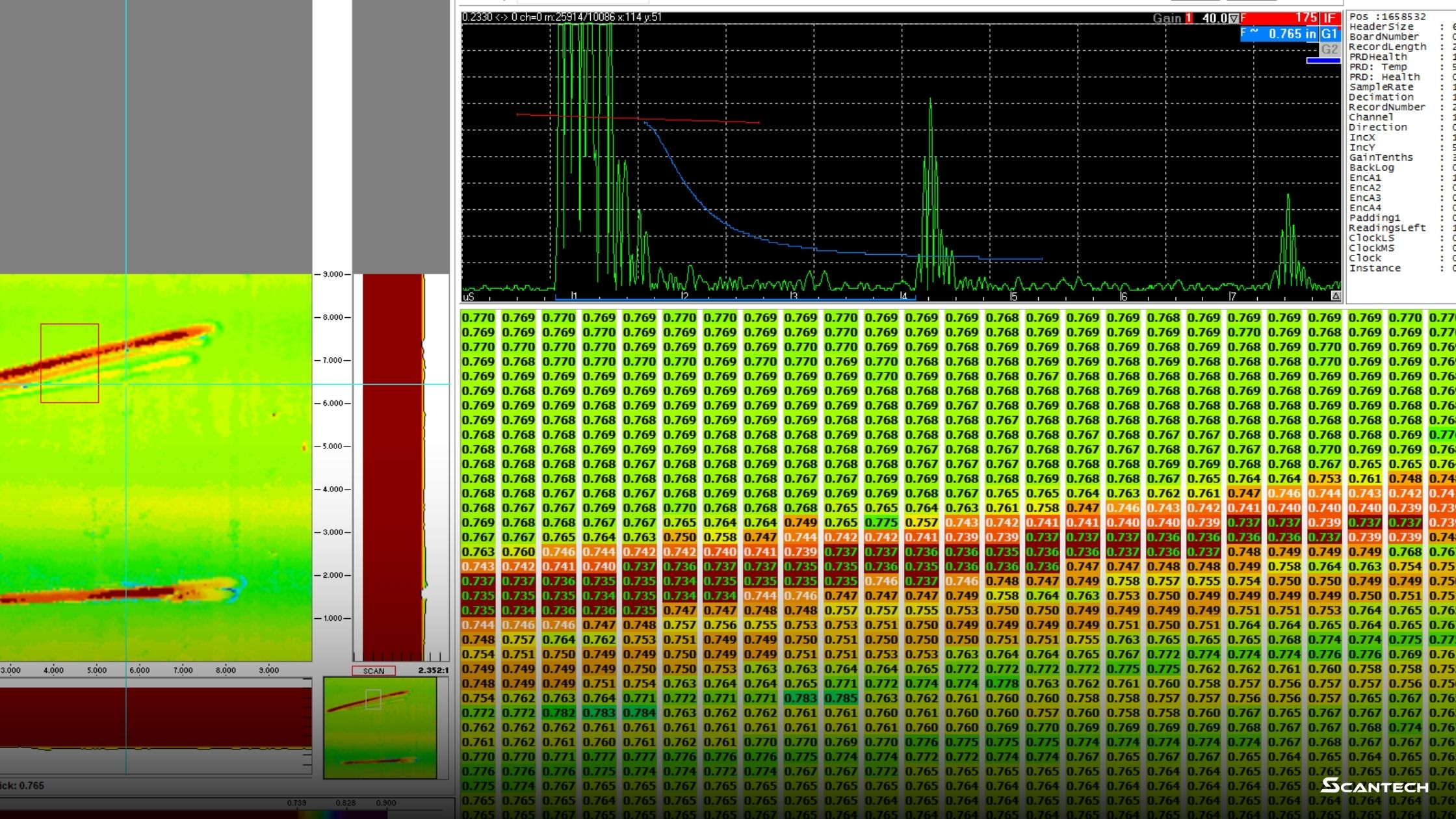

Documented ultrasonic thickness readings must support corrosion-rate calculations and remaining-life assessments.

-

Inspection records must include measurement traceability (calibration data, transducer/gauge identifier, and position encoding).

Why Automation Matters for Tank Scanning

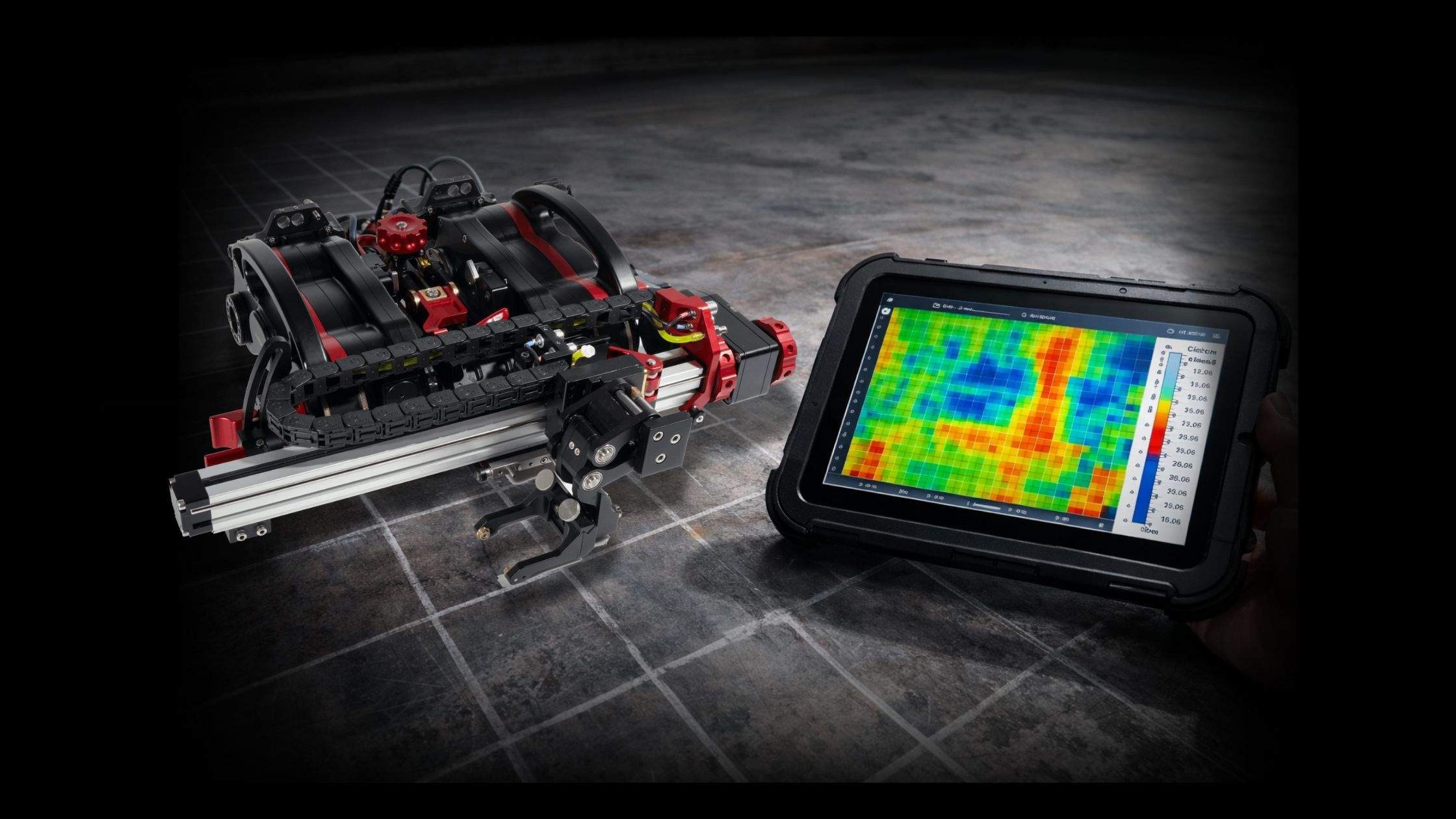

Automated scanning delivers uniform grid coverage, repeatable probe coupling, and consistent position encoding — all of which improve data quality and reduce manual variability. Automation reduces total inspection time while producing outputs that are easier to audit and integrate into code-compliant reports.

Key Elements of an Automated UT Setup for Tanks

1. Hardware Suitable for the Asset

Select a scanner designed for the tank diameter and access method. For narrow manways or small pipe entry, choose a platform proven for tight radii; for large tanks, choose a platform with adequate payload and modular attachments.

2. Defined Scan Grid & Resolution

Specify and document the grid spacing and resolution before scanning. Grid resolution directly impacts defect detectability and measurement uncertainty, so choose spacing that satisfies the inspection acceptance criteria.

3. Consistent Probe Coupling

Adopt hardware and probe mounts that ensure repeatable coupling across a scan (constant contact force, stable probe orientation, and reliable couplant delivery). Consistent coupling reduces false indications and improves repeatable thickness measurements.

4. Integration with Tank Access & Logistics

Design the inspection plan around available access points, safe rigging, and required tooling. Scanner selection should consider how easily units are deployed, retrieved, and reconfigured on the asset.

5. Data Management & Code-Compliant Output

Capture position-encoded UT data with timestamps and calibration metadata, then export reports that enable API 653 calculations (corrosion rate, min remaining thickness, inspection interval guidance). Ensure the reporting format preserves traceability for audit and engineering review.

Deployment Workflow — Step-by-Step

-

Pre-inspection planning: Gather drawings, specify scan grid and resolution, confirm access and safety requirements.

-

Scanner setup & calibration: Mount the scanner and set probe parameters; verify calibration against reference standards.

-

Scanning pass: Execute the automated passes with defined raster/drive increments and monitor live data for coupling quality.

-

Quality assurance: Review raw datasets for dropout, coupling anomalies, and positional errors; re-scan as required.

-

Generate code-compliant report: Produce outputs that include measurement tables, corrosion-rate inputs, and positional maps suitable for API 653 assessment.

-

Inspection decision & remediation planning: Use the measured data and API calculations to plan repairs, remaining-life estimates, or follow-up inspection intervals.

Why Choose This Approach?

-

Reduced downtime: automation covers more area faster and with repeatable results.

-

Higher confidence in data: consistent mechanics and position encoding lower variation and reporting risk.

-

Scalable workflows: automated scans can be reproduced across assets and used in trending and RBI programs.

Explore Related Platforms

-

XR Spider —deliver precision corrosion mapping for tanks, pipes, hulls, and vessels with high-speed, high-resolution data.

-

Vertex & Apex Platforms — for modular scan arms, larger payloads, and flexible drive options.

-

Radix Weld Scanner — high-resolution weld data capture and efficient reporting for manual or automated inspection.

Ready to Upgrade the Inspection Workflow?

Automation improves data integrity, traceability, and reporting efficiency for API 653 tank assessments. Evaluate scan resolution, coupling repeatability, and report outputs when selecting a platform to ensure compliance and useful engineering results