Table of Contents

In today’s industrial landscape, minimizing downtime is crucial. Downtime disrupts operations, leading to significant financial losses. It’s essential to keep machinery and equipment running smoothly. One effective strategy is using advanced corrosion mapping technology.

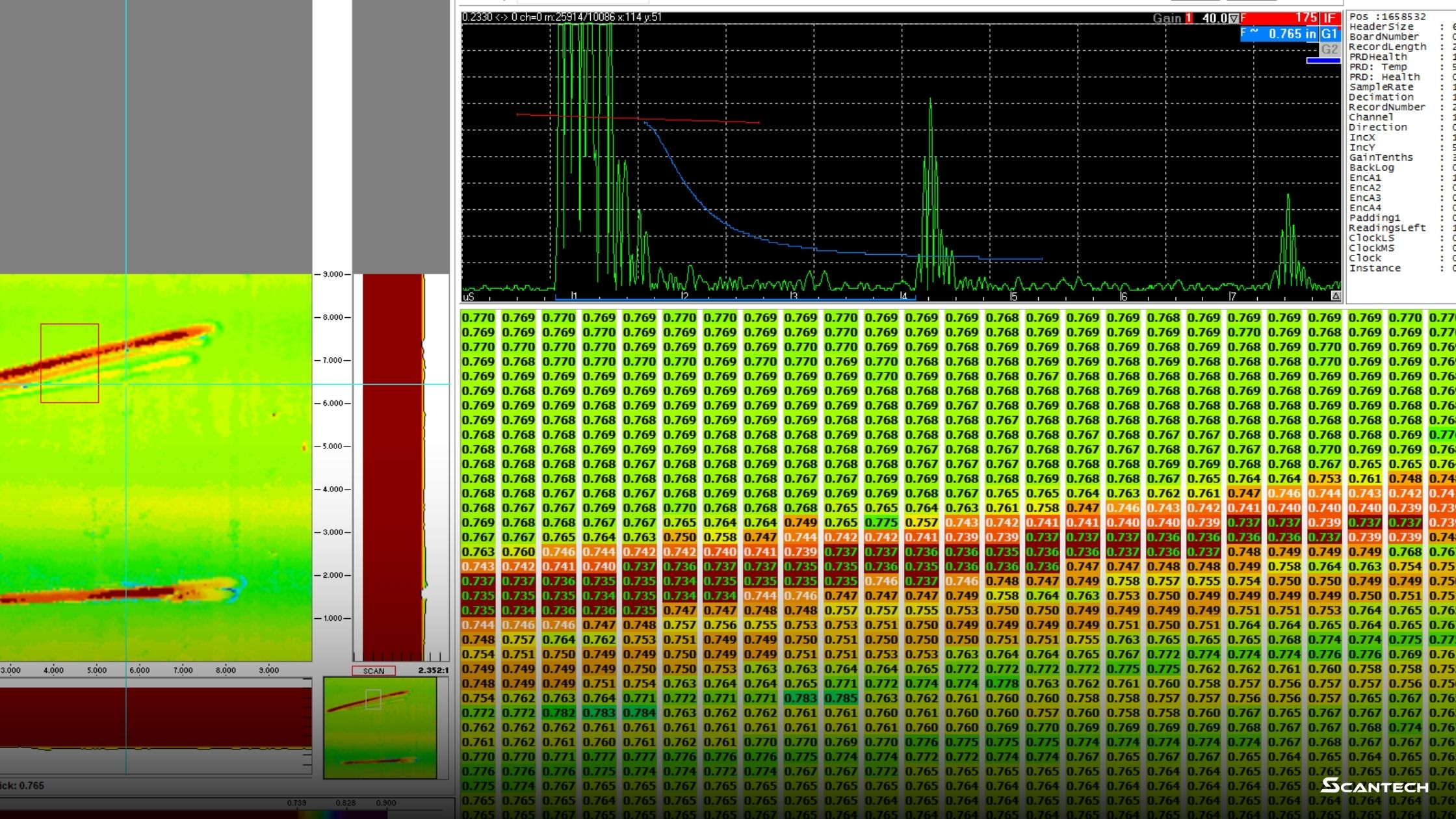

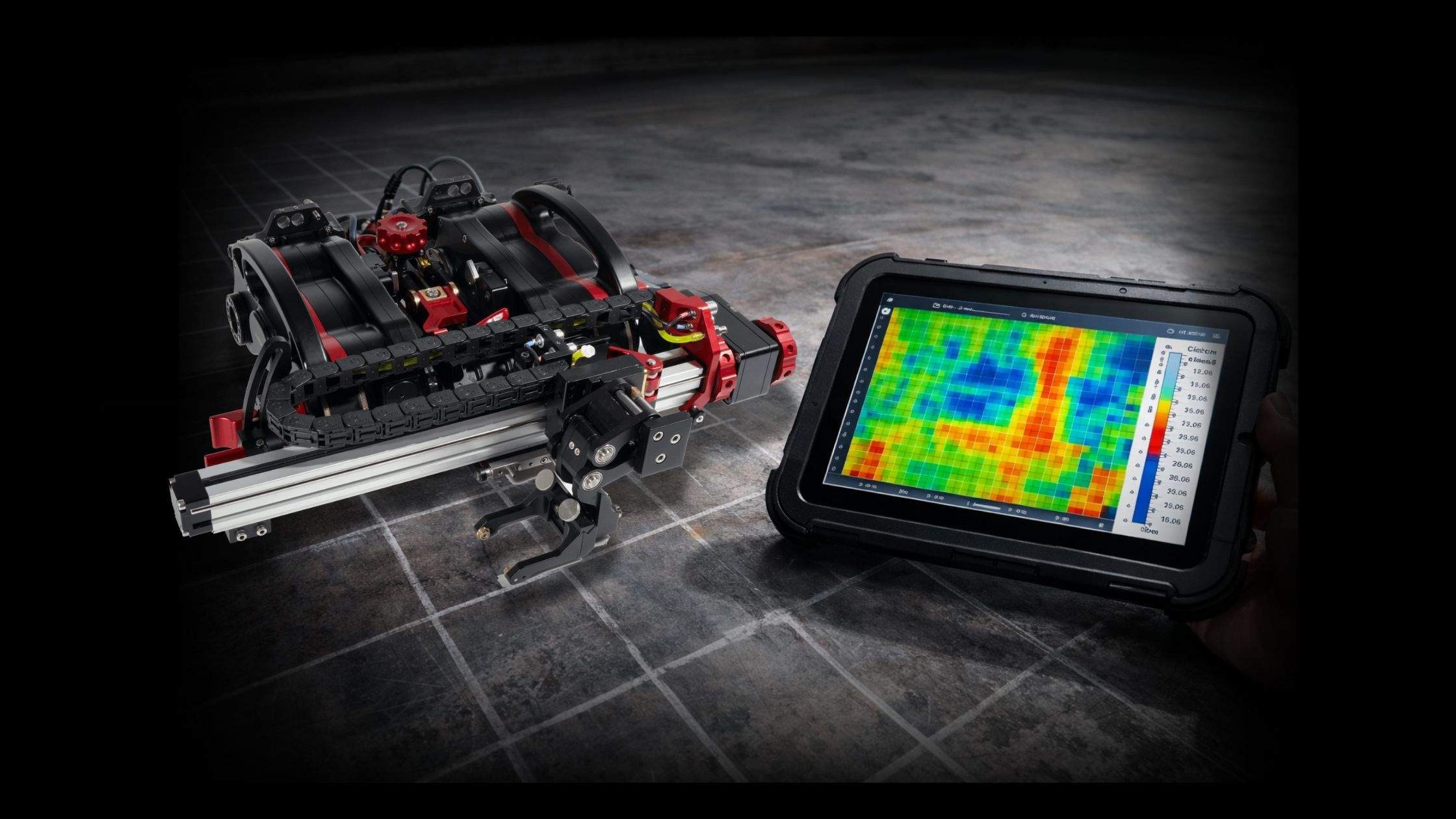

This cutting-edge technology has changed how industries approach maintenance. It is especially impactful in non-destructive testing (NDT). Corrosion mapping technology uses high-frequency sound waves to inspect and analyze materials. This method helps detect potential issues before they cause equipment failure. As a result, problems are addressed early, reducing the likelihood of unexpected downtime.

Achieving High Precision and Accuracy in Maintenance Inspections

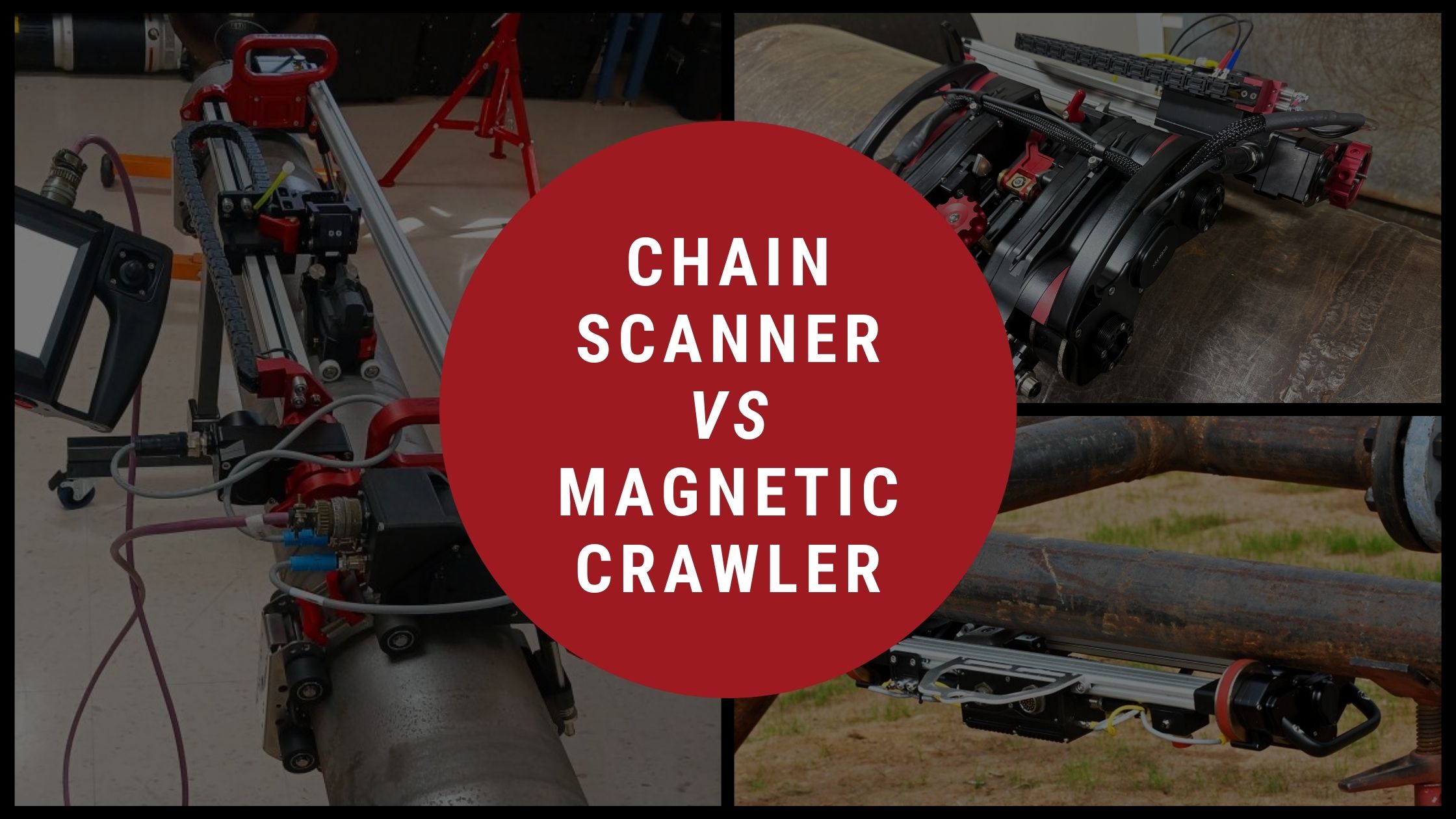

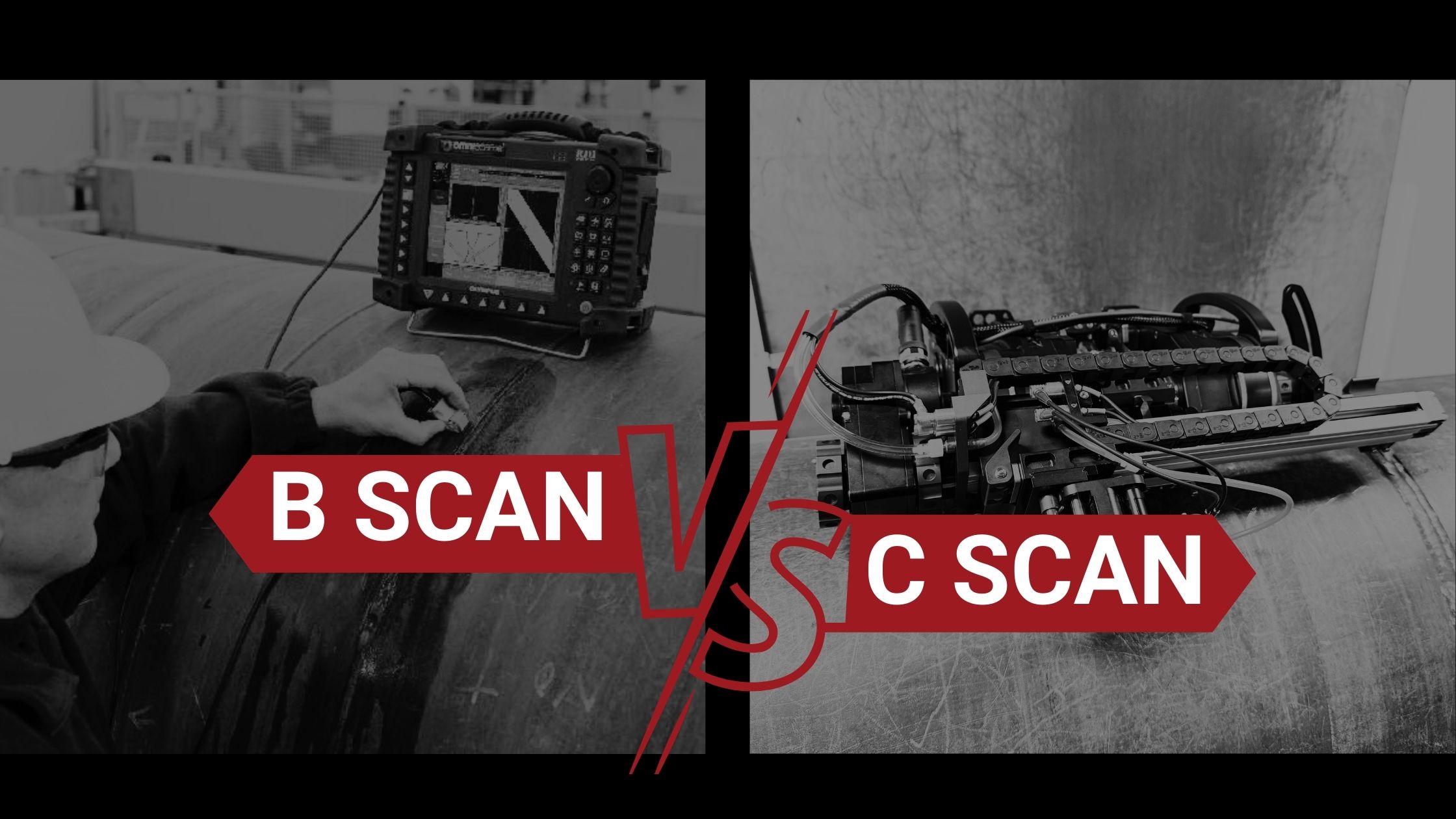

Advanced corrosion mapping offers significant benefits. One of its main advantages is the precision it provides. Traditional inspection methods often rely on manual processes. These methods can be time-consuming and prone to human error. In contrast, corrosion mapping systems use automated technology. This automation generates detailed images of internal structures. These images allow for thorough examinations without dismantling equipment. As a result, inspections can occur more frequently and with greater accuracy. This ensures potential issues are identified and resolved before they escalate.

Boosting Efficiency in Maintenance Operations

Efficiency is another critical benefit of corrosion mapping. Automated systems scan large areas rapidly. This process provides comprehensive data much faster than manual methods. The speed and accuracy of these systems reduce the time needed for maintenance activities. Consequently, industries can minimize downtime and ensure smooth operations. Targeting maintenance efforts more effectively also saves time and resources.

Enhancing Workplace Safety Through Early Detection

Safety is a top priority in industrial environments. Advanced corrosion mapping technology plays a vital role in improving safety. By detecting corrosion-related issues early, industries can prevent accidents. This proactive approach ensures a safer working environment. It is especially important in sectors where infrastructure failure could have severe consequences.

Utilizing Data-Driven Insights for Proactive Maintenance

Another strength of corrosion mapping is its ability to continuously monitor equipment. This technology collects valuable data over time. Industries can use this data to identify trends and predict potential failures. This information allows for optimized maintenance schedules. A data-driven approach not only prevents downtime but also extends the lifespan of equipment.

Long-Term Benefits of Implementing Corrosion Mapping Technology

Adopting advanced corrosion mapping technology offers long-term benefits. The initial investment may be higher than traditional methods. However, the long-term savings far outweigh the costs. Reduced labor expenses, minimized downtime, and extended equipment life all contribute to a higher return on investment (ROI). These factors make corrosion mapping a financially sound choice for industrial maintenance.

As industries continue to adopt advanced corrosion mapping technology, it becomes clear that this tool is essential. By providing accurate, real-time data and extending equipment lifespan, this technology offers a comprehensive solution. For companies looking to optimize their maintenance processes, integrating advanced corrosion mapping is a strategic move.