Home » Products » NDT Ultrasonic Scanners » The Apex | Modular Universal Scanner Platform

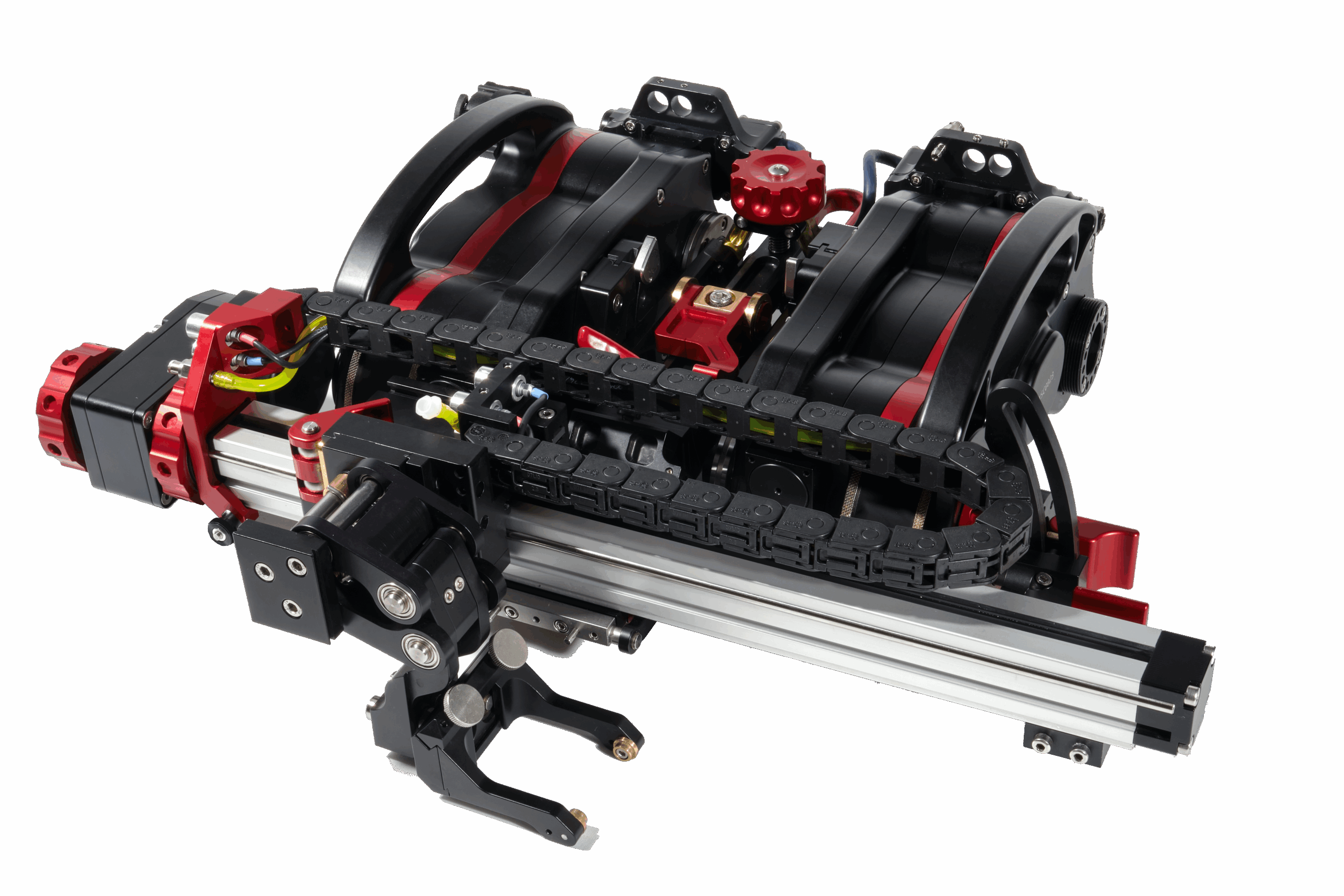

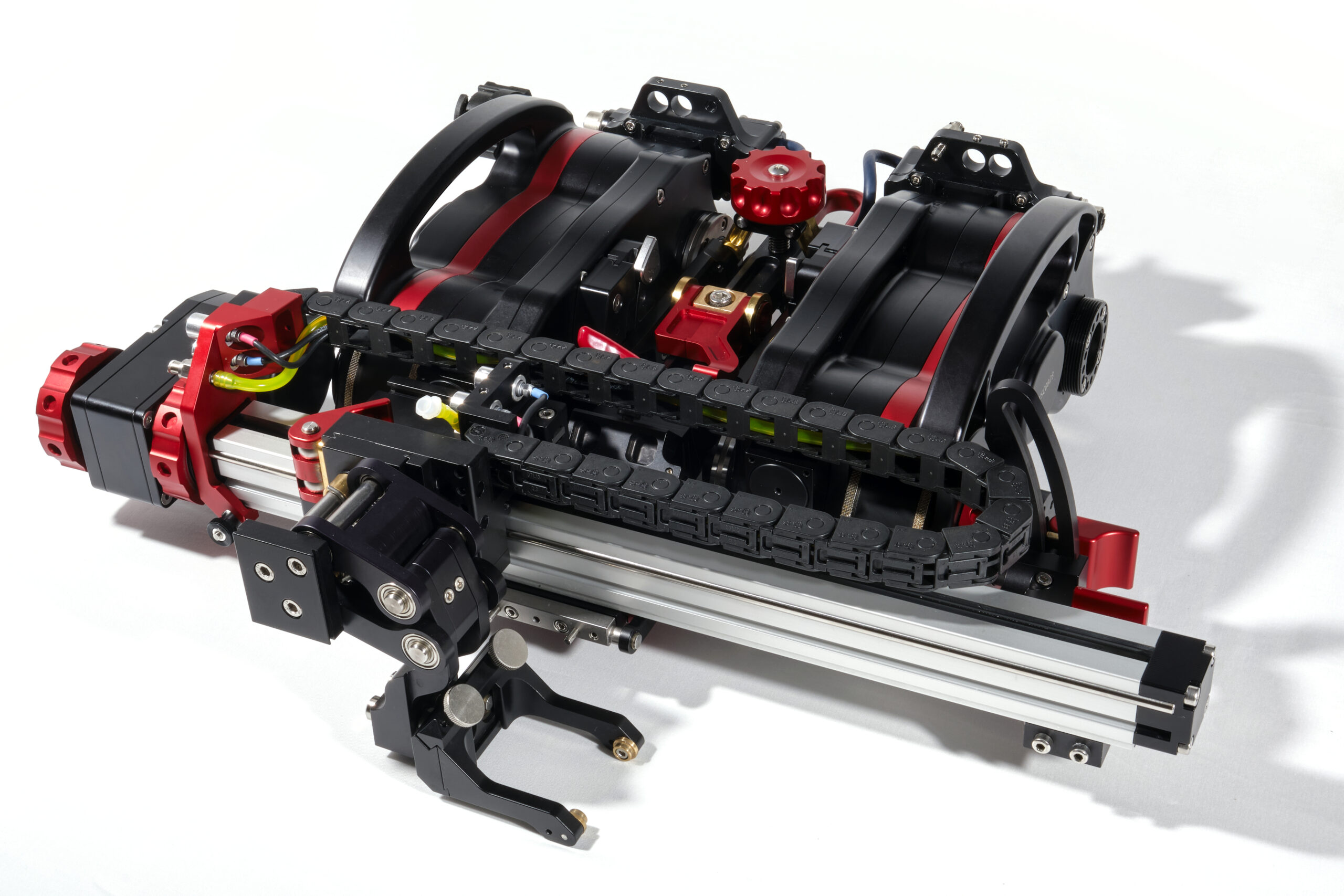

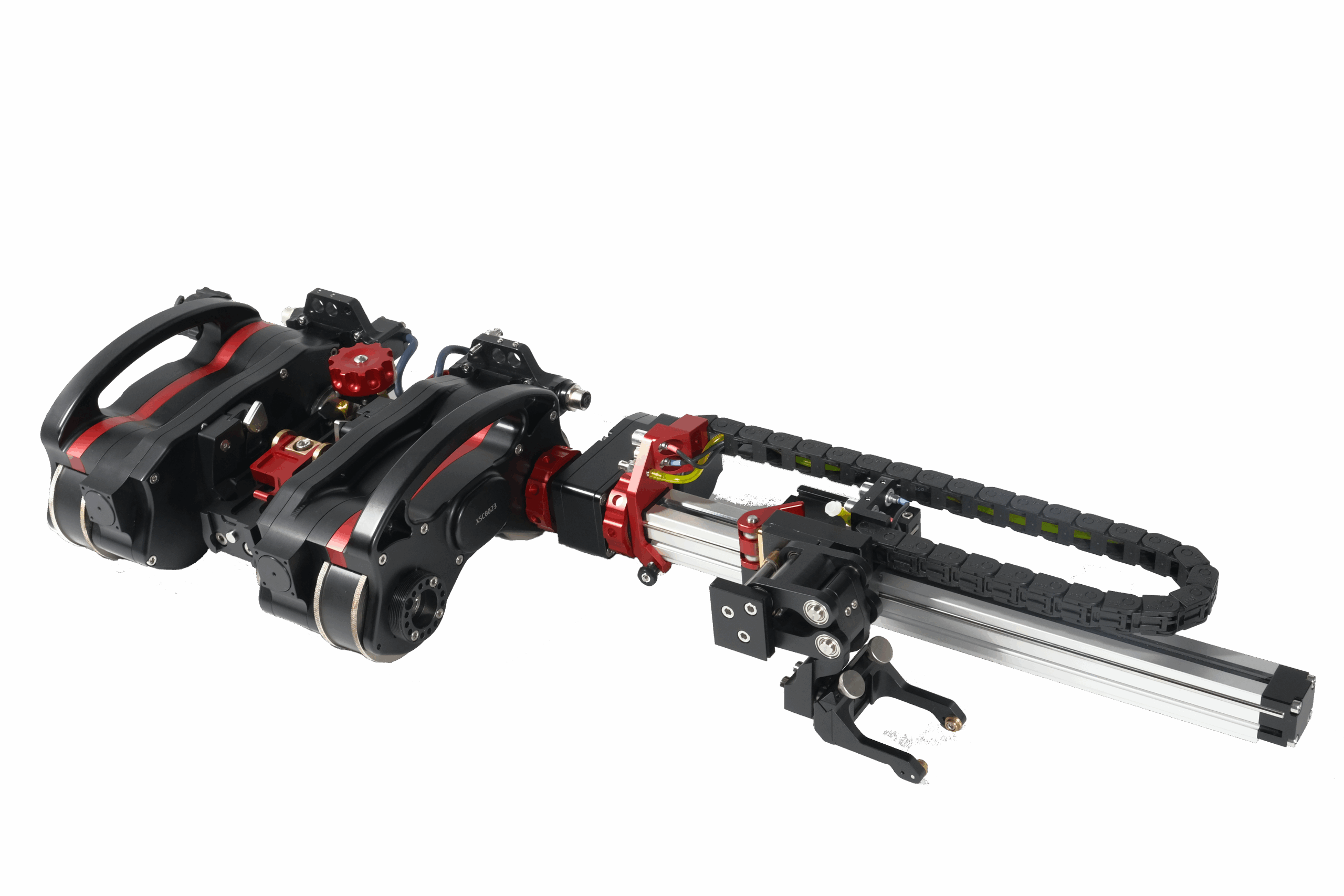

The Apex Scanner from ScanTech is a modular, universal scanning platform designed for high-precision and versatile scanning applications. It combines rugged, field-proven components with advanced technology to ensure reliability and portability in various industrial settings.

This Scanner is designed to meet the rigorous demands of industrial inspections, offering unmatched versatility and performance.

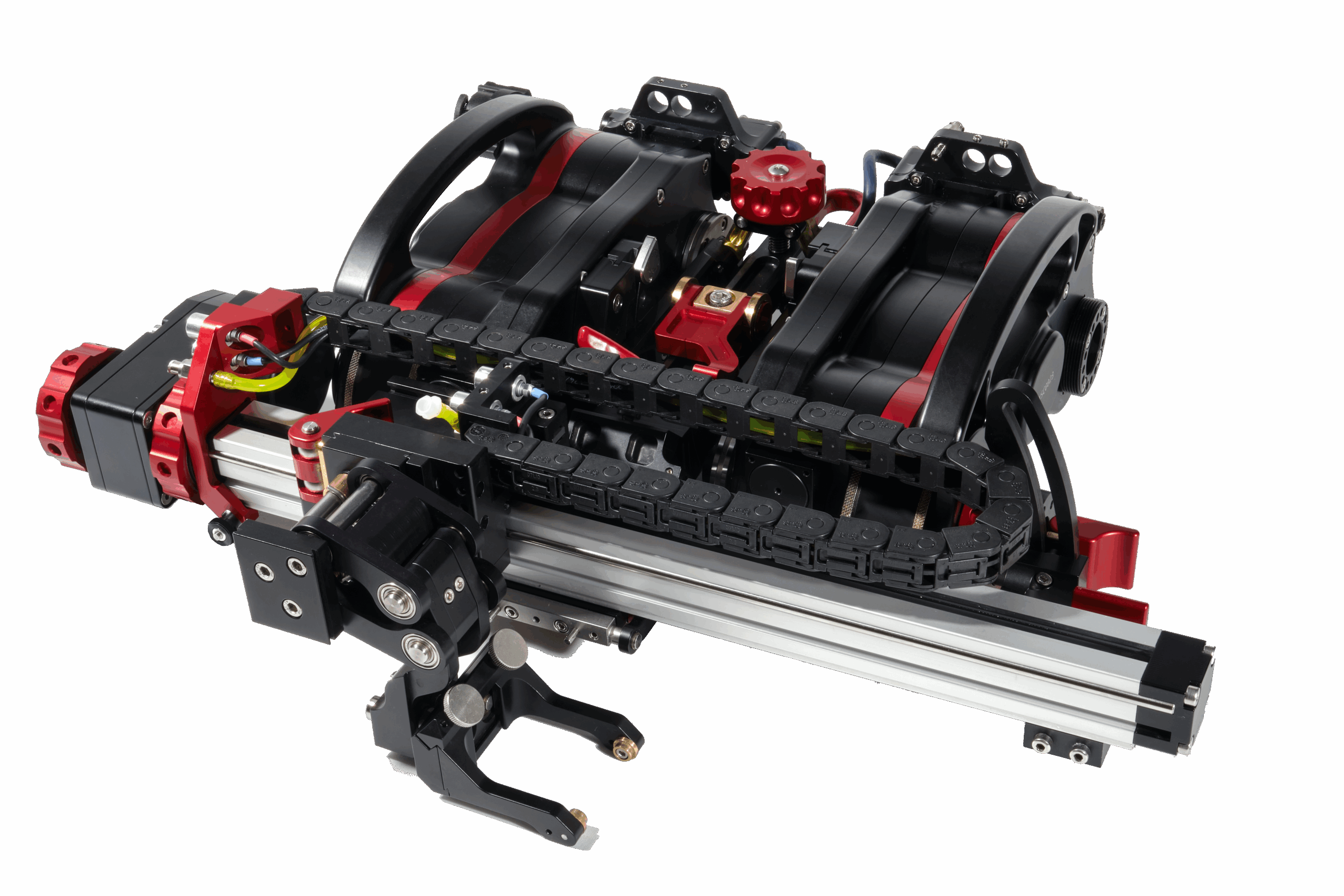

Portability and Reliability: Field-proven probe attachments ensure durability and ease of use.

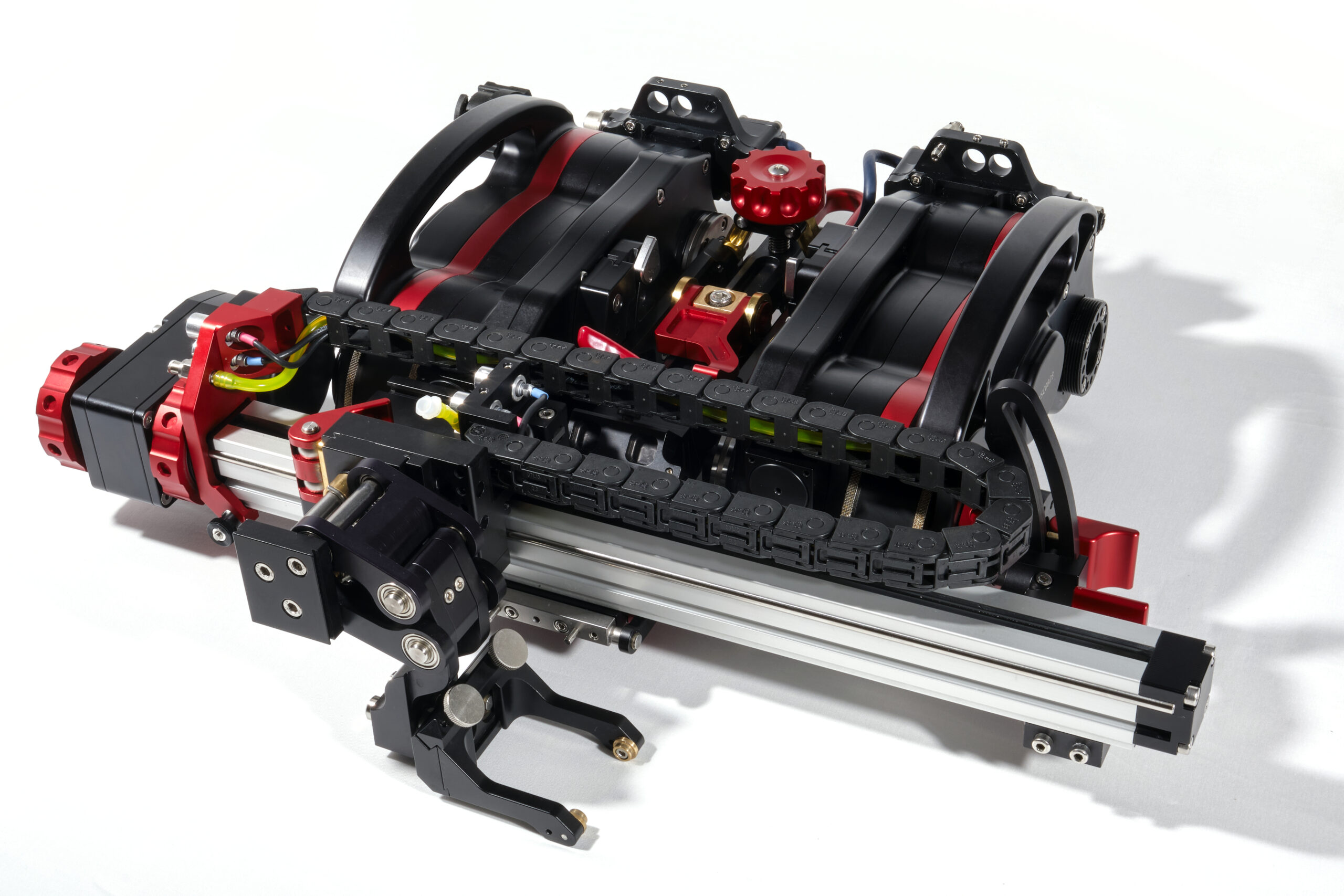

Enhanced Stability: Patented Anti-Tip probe gimbal and near-constant force spring design for superior UT signal return and quality readings.

Environmental Resistance: Proprietary straight line motion probe mechanism with sealed rotary bearings withstands stronger reaction forces and harsh conditions.

Greater Flexibility: Common button type probe mounts fit most PA probes, offering a wide range of probe options.

Improved Rigidity: Rigid probe width adjustment with dovetail lock for enhanced performance in real-world conditions.

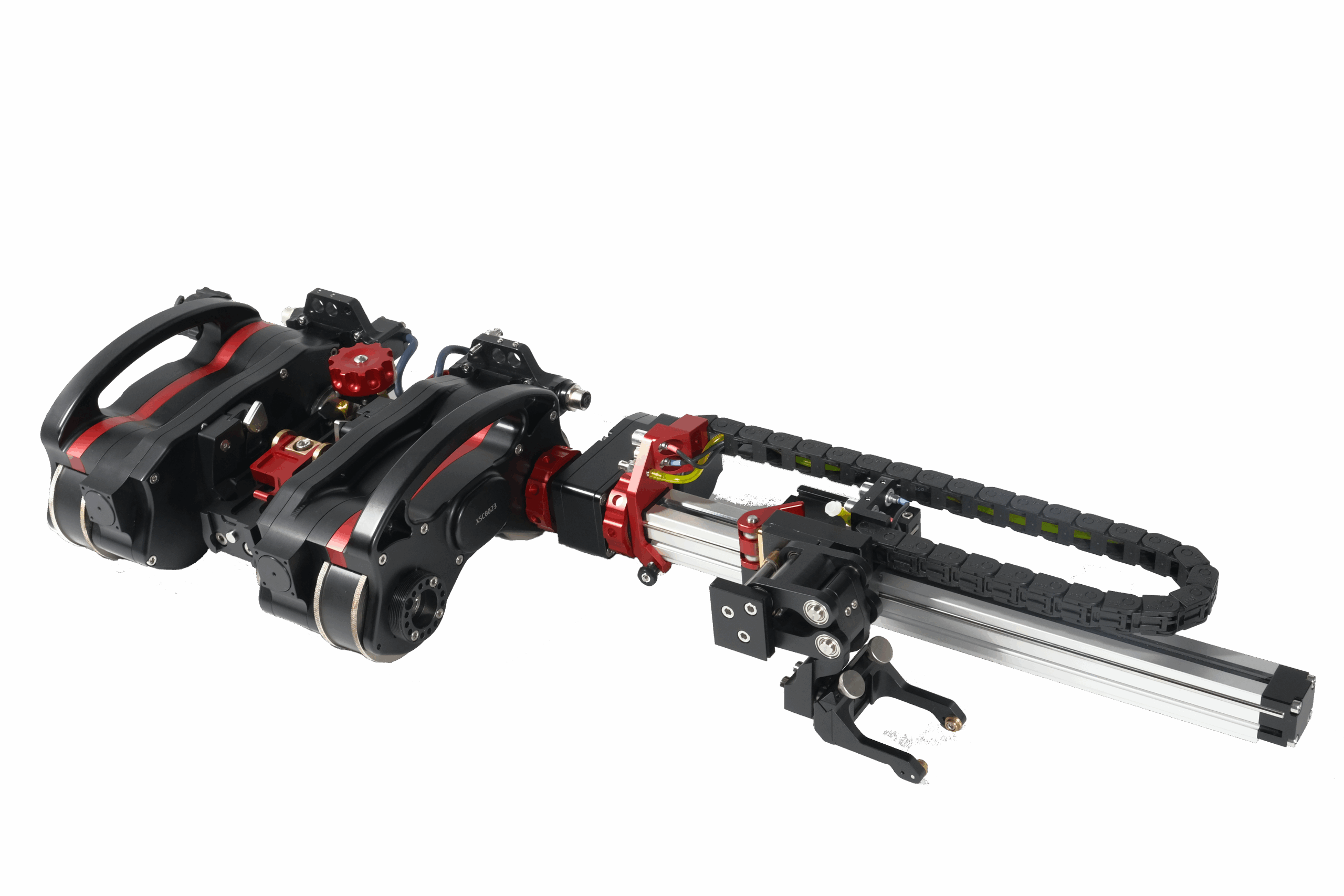

STC Distributed, Modular Control System: Minimizes conductors for a lighter umbilical and easy expandability for additional axes or features.

High Compliance Suspension: New mid-section body design enhances compliance.

Toolless Adjustments: Attachment points and wheel angle adjustments for small radii ensure quick setup and flexibility.

ACR Design: Probe coupling design reduces turbulence and water consumption, with the latest spring design offering near-constant contact force.

Weld Inspections: Ensures precise and reliable weld scanning with minimal turbulence and water consumption.

Corrosion Mapping: Provides accurate and efficient mapping of corrosion in various industrial settings.

General Ultrasonic Testing: Suitable for a broad range of ultrasonic testing applications, including B-Scan, C-Scan, and more.

New Mid-Section Body Design: High compliance suspension for better adaptability.

Toolless Attachment Points: Simplifies wheel angle adjustments for small radii.

Spring Design: Offers the most constant contact force over full travel.

Probe Guide Hardware: Ensures reliability and ruggedness in lightweight, modular, multi-probe configurations.

Quick Adjustments: Ensure proper probe contact on pipe surfaces for both circumferential and longitudinal scans.

Anti-Tip Probe Mechanism: Prevents probes from flipping over.

The Apex Scanner boasts compact dimensions with a length of 10.5 inches, width of 10.8 inches, and height of 4.95 inches, making it highly portable. Weighing just 19 lbs, it features robust drive units with speeds up to 36 inches per second and high torque output. The scanner includes advanced probe mechanisms for increased stability and environmental resistance, ensuring reliable performance in industrial conditions. Explore the full specifications for more details on its capabilities.

Schedule a meeting with our experts to explore how our advanced NDT solutions can benefit your operations.

ScanTech Instruments has been an invaluable partner to MFE Inspection Solutions for several years, providing cutting-edge ultrasonic testing scanners that consistently deliver precision and reliability in the most challenging environments. As a leader in non-destructive testing, ScanTech's dedication to innovation and quality aligns seamlessly with MFE's commitment to offering the best inspection solutions on the market. Under the leadership of Alan Dorsey, President of ScanTech, the company has reached new heights in the inspection industry. Alan's extensive background in inspection and his deep understanding of the industry's demands have been instrumental in shaping ScanTech's product offerings to meet the evolving needs of our clients. His commitment to excellence and his hands-on experience in the field ensure that every ScanTech product is engineered with the inspector in mind, providing unmatched reliability and efficiency.

I am impressed with ScanTech’s new website and amazing new logo! The modern and intuitive design of the website makes navigation much easier and more enjoyable. Additionally, the new logo is simply spectacular, perfectly reflecting the innovation and quality that ScanTech represents.