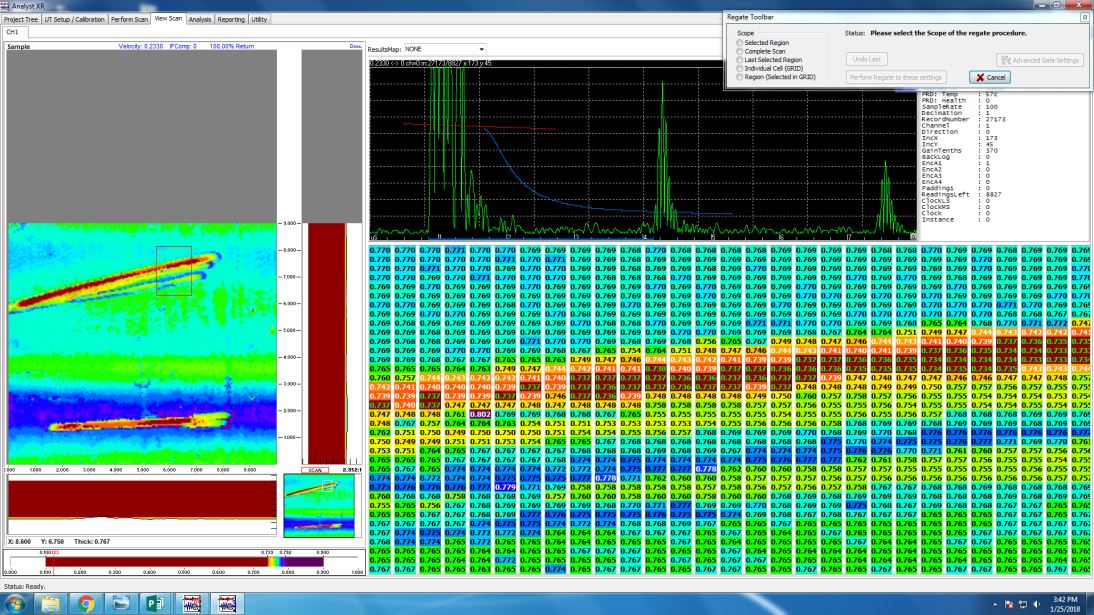

Digital radiography is reshaping how pipe weld inspection is performed in the field. As inspection teams move away from traditional film radiography, the focus is no longer just on speed—it is on control, consistency, and data confidence.

For pipeline and process piping applications, digital radiography offers clear advantages. When paired with mechanical tools, it becomes a more repeatable and efficient method for evaluating weld integrity.

Why Weld Inspection Requires a Purpose-Built Solution

Pipe weld inspection presents challenges that flat or improvised radiography setups struggle to overcome:

- Curved surfaces and varying pipe diameters

- Limited access around installed piping

- Inconsistent source-to-detector alignment

- Repeated setups across multiple welds

Traditional film radiography can manage these conditions, but often at the cost of time, consumables, and repeat exposures. Digital radiography removes many of those inefficiencies—but only when detector positioning and movement are properly controlled.

This is where pipe-specific radiography tools make a measurable difference.

The Advantages of Digital Radiography for Weld Inspection

When applied correctly, digital radiography improves both workflow and inspection quality for pipe welds:

- Immediate image review eliminates film processing delays

- Enhanced defect visibility through digital contrast adjustment

- Fewer retakes due to consistent detector positioning

- Cleaner inspection workflows without chemicals or film handling

For weld inspection, these benefits translate into faster decisions, reduced downtime, and stronger documentation for quality assurance and compliance.

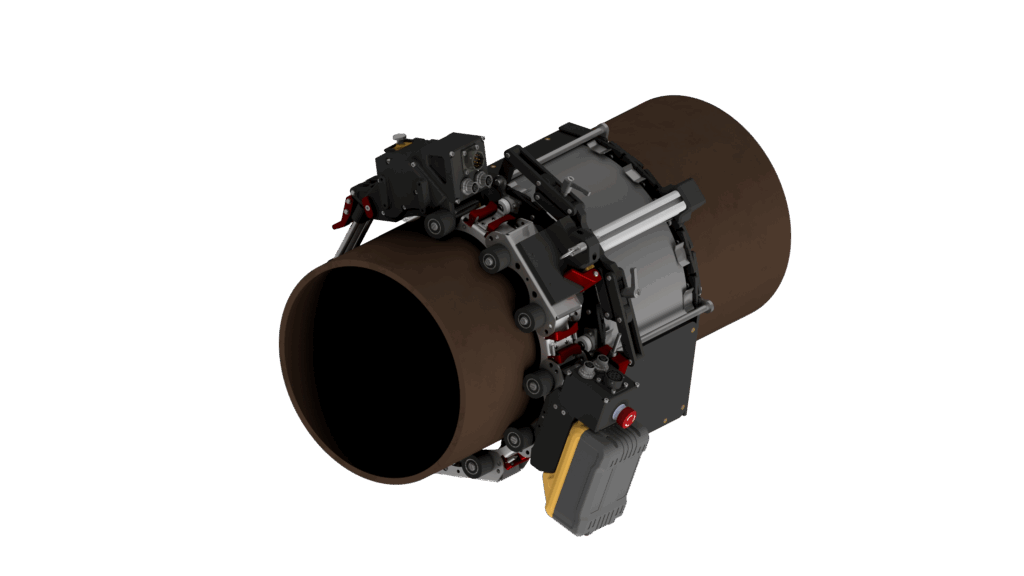

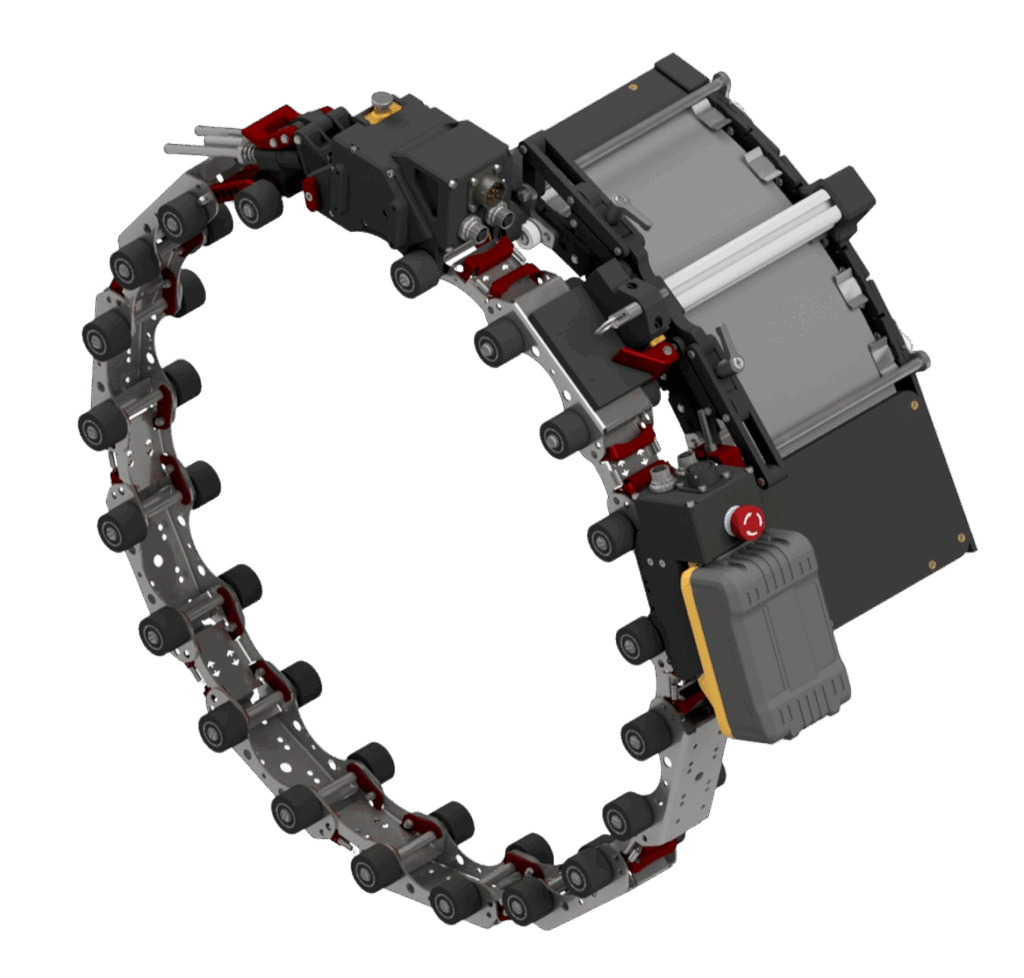

CLIXRT: A Modular Chain Scanner Designed for Pipes

The CLIX modular chain scanner was developed to address one of the biggest challenges in pipe radiography: maintaining stable, repeatable positioning around a round asset.

Unlike flat or improvised fixtures, the CLIX wraps securely around the pipe using a modular chain design, allowing controlled movement and consistent alignment throughout the inspection.

For digital radiography pipe weld inspection, CLIX provides:

- Stable detector travel around the pipe circumference

- Compatibility with a wide range of pipe diameters

- Support for long or continuous scan paths

- Fully wireless RT scanning configurations

By controlling movement and alignment, variability is reduced between inspections and helps ensure that digital radiography images remain consistent from weld to weld.

Learn more about the CLIX system: CLIX – Modular Chain Scanner for Pipe Inspection

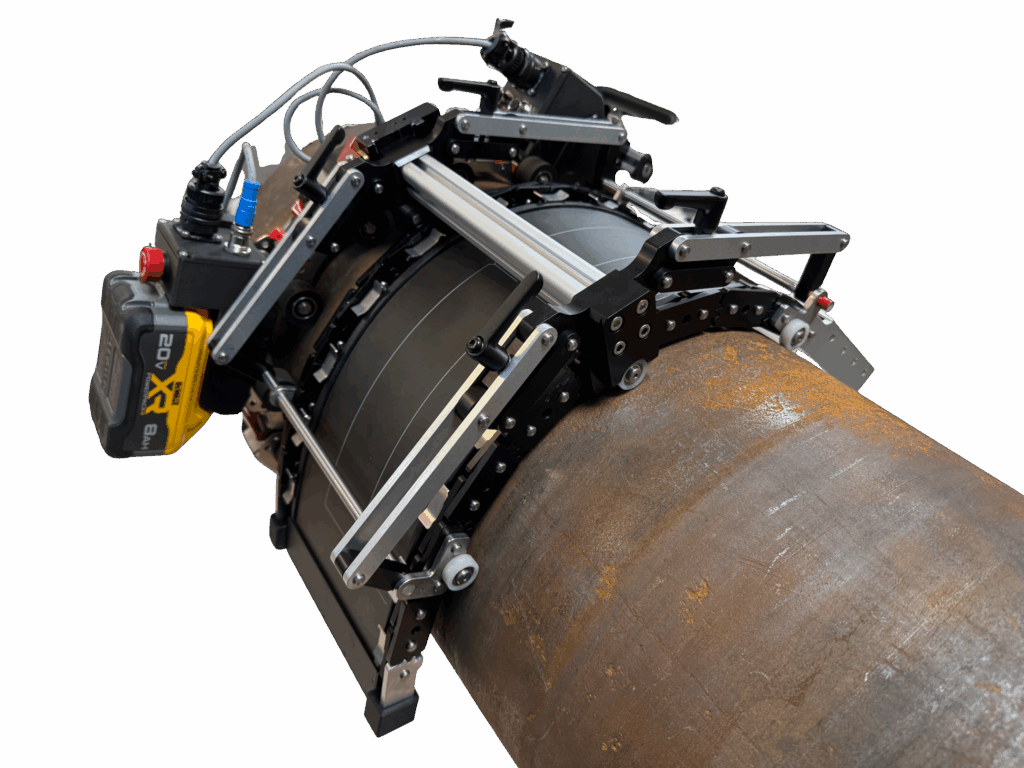

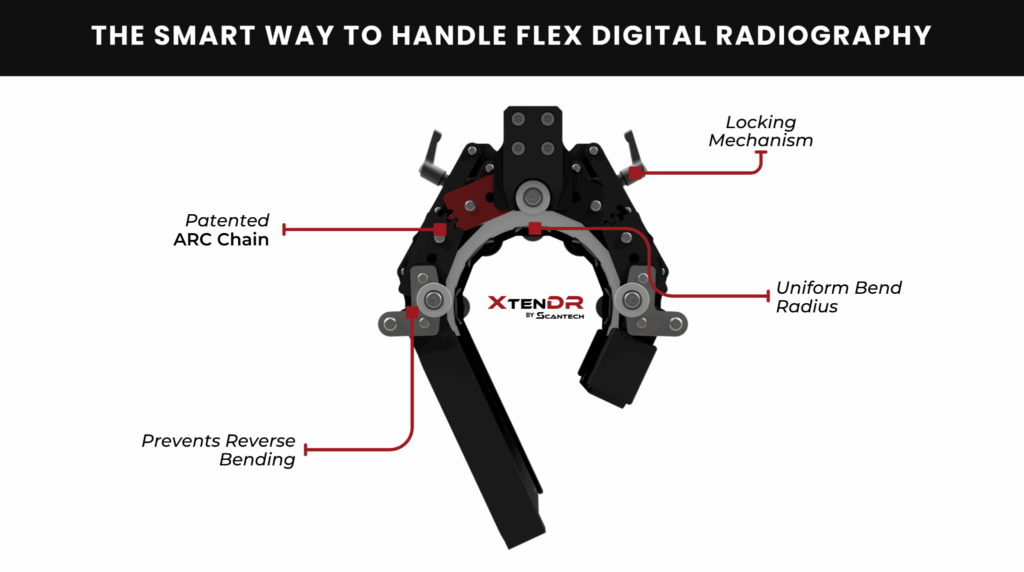

XtenDR: Precise Panel Positioning at the Weld

While CLIX manages movement around the pipe, detector positioning at the weld remains critical to image quality. The XtenDR panel holder was designed specifically to secure digital radiography panels on curved pipe surfaces.

XtenDR maintains proper alignment and stand-off during inspection, helping eliminate common issues such as panel drift or inconsistent positioning.

For pipe inspection, XtenDR supports:

- Reliable panel placement on curved surfaces

- Reduced setup variability between inspections

- Repeatable, defensible inspection results

When used together, CLIX and XtenDR form a mechanical solution that supports digital radiography where it matters most.

Explore the XtenDR here: XtenDR Digital Radiography Panel Holder

Designed for Pipe Inspection, Not Adapted to It

A common limitation of digital radiography systems is trying to adapt flat, general-purpose equipment to round assets. ScanTech’s approach focuses on pipe inspection first.

Both CLIX and XtenDR are engineered for real-world pipe weld inspection conditions, including:

- Variable diameters

- Field-deployed inspection workflows

- Repetitive weld inspections that demand consistency

This design philosophy reduces setup time, improves repeatability, and supports higher-quality RT data without adding complexity in the field.

A Practical Step Forward for RT Weld Inspection

Digital radiography is not simply a replacement for film. When paired with pipe-specific mechanical tools, it becomes a more controlled and reliable inspection method.

By combining a modular chain scanner like CLIX with a purpose-built panel holder like XtenDR, inspection teams gain better control over detector positioning, improved image consistency, and fewer variables that can compromise weld inspection results.

For pipe inspection, digital radiography delivers the most value when the tools are designed for the asset—not forced to adapt to it.