High-resolution ultrasonic data takes longer to acquire, but it prevents missed indications, eliminates costly rework, and produces defensible results for API 653 tank inspections, pipeline corrosion mapping, and vessel assessments. Low-resolution scans may save a few minutes during acquisition but often hide localized thinning, pitting, and critical defects that directly impact asset integrity decisions. Time savings gained upfront are quickly erased when scans are repeated, audits are delayed, or defects are overlooked.

Why Data Quality in UT Scanning Matters More Than Scan Speed

Data quality is the foundation of every ultrasonic inspection. Whether the goal is a detailed corrosion map, an API 653 tank evaluation, or a vessel profile, the clarity of the dataset determines the accuracy of the decisions made from it.

Inspection teams face constant pressure to move fast—turnarounds, outages, and tight schedules often reward speed. But when speed reduces resolution, the result is incomplete or unreliable data. Low-density scans frequently lead to:

- Missed corrosion under insulation

- Inaccurate wall-loss characterization

- Ambiguous readings that require technician interpretation

- Rejected reports during compliance reviews

- Repeat inspections and schedule delays

In all these cases, the time “saved” during data acquisition becomes time lost later—along with higher cost and greater operational risk.

The Tradeoff Between Resolution and Scan Time

Ultrasonic corrosion mapping depends on consistent raster spacing and pixel density. The tighter the raster spacing, the more complete and detailed the final image becomes. However, tighter spacing also increases the total number of passes, which extends the scan duration.

High-Resolution Scan (tight increments):

- More pixels per area

- Greater defect visibility

- Longer runtime

- Best for pitting, localized wall loss, and detailed corrosion mapping

Low-Resolution Scan (wide increments):

- Fewer data points

- Reduced clarity

- Faster runtime

- Higher risk of missed indications

The relationship is not linear—doubling the raster spacing does not simply halve the detail; it can eliminate entire defect signatures from the dataset. When visual examples are placed side-by-side, the difference becomes immediately clear: high-resolution images capture pitting and isolated thinning, while low-resolution images blur or hide these features completely.

This is why resolution settings matter as much as scanner performance. Speed without fidelity rarely produces reliable results.

Compare how resolution settings affect scan time using the Scan Time Estimator.

What Poor Data Quality Actually Costs

The consequences of insufficient resolution extend far beyond aesthetic clarity. Poor datasets affect field operations, regulatory compliance, and the reliability of long-term asset-management strategies.

Common downstream costs include:

- Re-scans: Low-resolution data often requires technicians to revisit the same area, doubling the total time spent.

- Turnaround delays: Ambiguous indications can delay decision-making during time-sensitive outages.

- Incorrect callouts: Undetected pitting or thinning results in inaccurate repair scopes.

- Nonconformance with API 653 reporting: Inspectors must provide defensible data; insufficient resolution leads to report revisions or rejection.

- Unplanned downtime: Missed defects escalate into failures or unexpected repair needs.

In every scenario, low-quality data creates more work, more cost, and more operational risk than high-resolution scanning ever would.

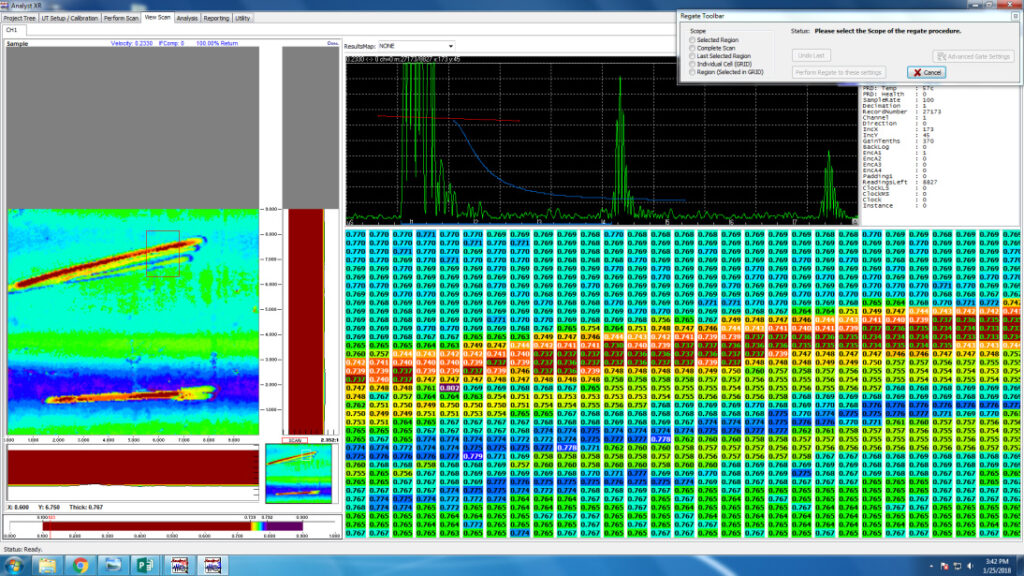

Resolution Case Example — How Scan Density Changes the Outcome

When the same inspection area is scanned twice using different resolution settings, the contrast can be dramatic:

High-Resolution Dataset:

- Clearly defined corrosion patterns

- Accurate depth and shape of thinning

- Reliable, repeatable analysis

- Strong visual evidence for audit and compliance

Low-Resolution Dataset:

- Pits and small-area defects appear smooth or disappear

- Corrosion boundaries are unclear

- Poor signal density leads to misinterpretation

- High likelihood of follow-up scans or disputed findings

Field technicians commonly encounter situations where a defect is clearly visible on a high-density C-scan but nearly invisible when the scan is repeated with a wider raster increment. This visual comparison will be included in the final blog layout to emphasize the point: resolution protects data integrity.

Why Scanner Design Matters for Data Quality

Mechanical stability directly affects the fidelity of ultrasonic data. A scanner must maintain equal, consistent pressure, accurate encoder tracking, and smooth probe motion, even when navigating complex surfaces or tight access points.

ScanTech’s systems are engineered specifically to support high-quality data acquisition:

- Proprietary constant-force pressure mechanisms maintain consistent coupling.

- Direct-drive gear systems eliminate belt and chain slippage.

- Stable encoder alignment produces accurate positioning data across every pass.

- Rigid probe holders prevent tipping, lift-off, and signal loss.

These design elements allow high-resolution scanning to be performed reliably—even at faster speeds—without compromising accuracy or coverage.

Software’s Role in Preserving Data Quality

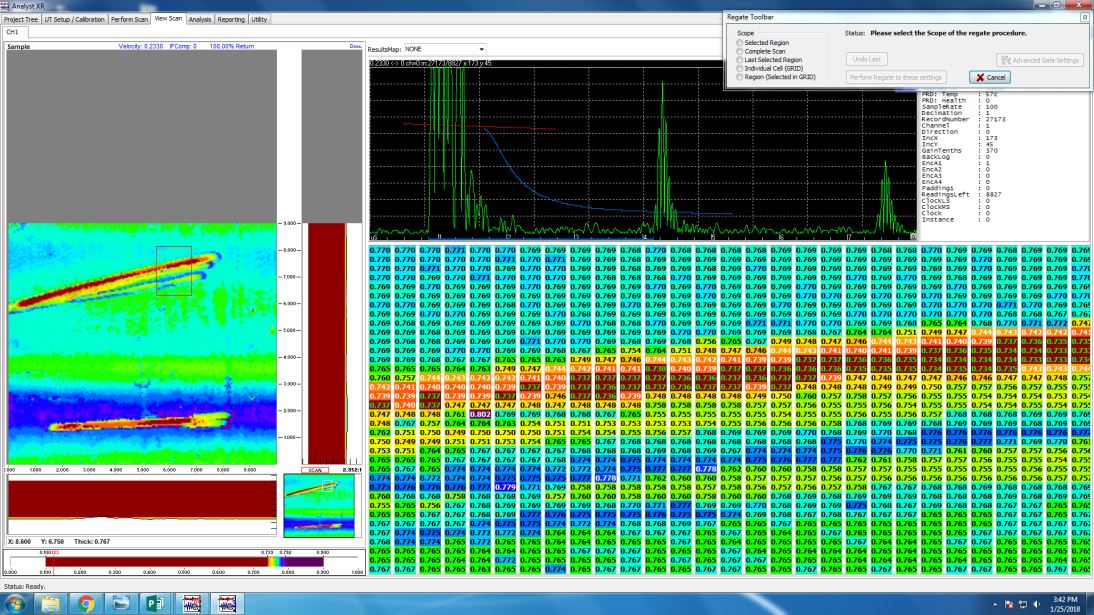

The mechanical system provides the stability, but the software determines what happens with the data collected. Our Analyst XR™ and Analyst X™ NDT software provide clarity, consistency, and confidence in results:

- Real-time visualization of coupling quality

- Automatic identification of dropouts or missed areas

- Built-in API 653 and B31G algorithms for standardized same day reporting

- High-density C-scan acquisition for detailed corrosion mapping

- Accurate B-scan profiles for tank wall and vessel inspections

High-quality data is only as good as the software interpreting it—strong visualization and real-time feedback ensure complete coverage and reliable reporting.

Water Coupling and Data Quality

Because ScanTech uses conventional ultrasonic testing with water as the couplant, consistent water delivery and smooth probe contact are essential for clean, high-quality waveforms. Proper coupling supports:

- Strong, stable ultrasonic transmission

- Minimal signal loss or noise

- Accurate thickness readings

- Reliable amplitude and return-path clarity

- Fewer dropout artifacts across the scan

High-quality coupling is one of the most important and overlooked contributors to overall data accuracy. For a deeper look at how water coupling supports reliable inspections, see the full overview on water-coupled ultrasonic testing.

Balancing Efficiency and Quality in the Field

Fast inspections are valuable, but only when the data is accurate. When poor resolution causes rework, delays, missed defects, the entire inspection loses efficiency.

A balanced approach connects:

- The right scanner and mechanism

- The right resolution settings

- The right software

- The right expectations for time and output

Inspection teams that prioritize data quality consistently achieve better outcomes, fewer rescans, and smoother turnarounds.

Quality Data Saves More Time Than It Costs

High-resolution ultrasonic data gives inspectors the clarity needed for accurate decisions, dependable reporting, and long-term asset confidence. Low-resolution scans may seem faster, but they introduce risk, uncertainty, and extra work. In the end, what seems efficient early on often turns into more time spent later.