Table of Contents

Precision, Portability and Performance

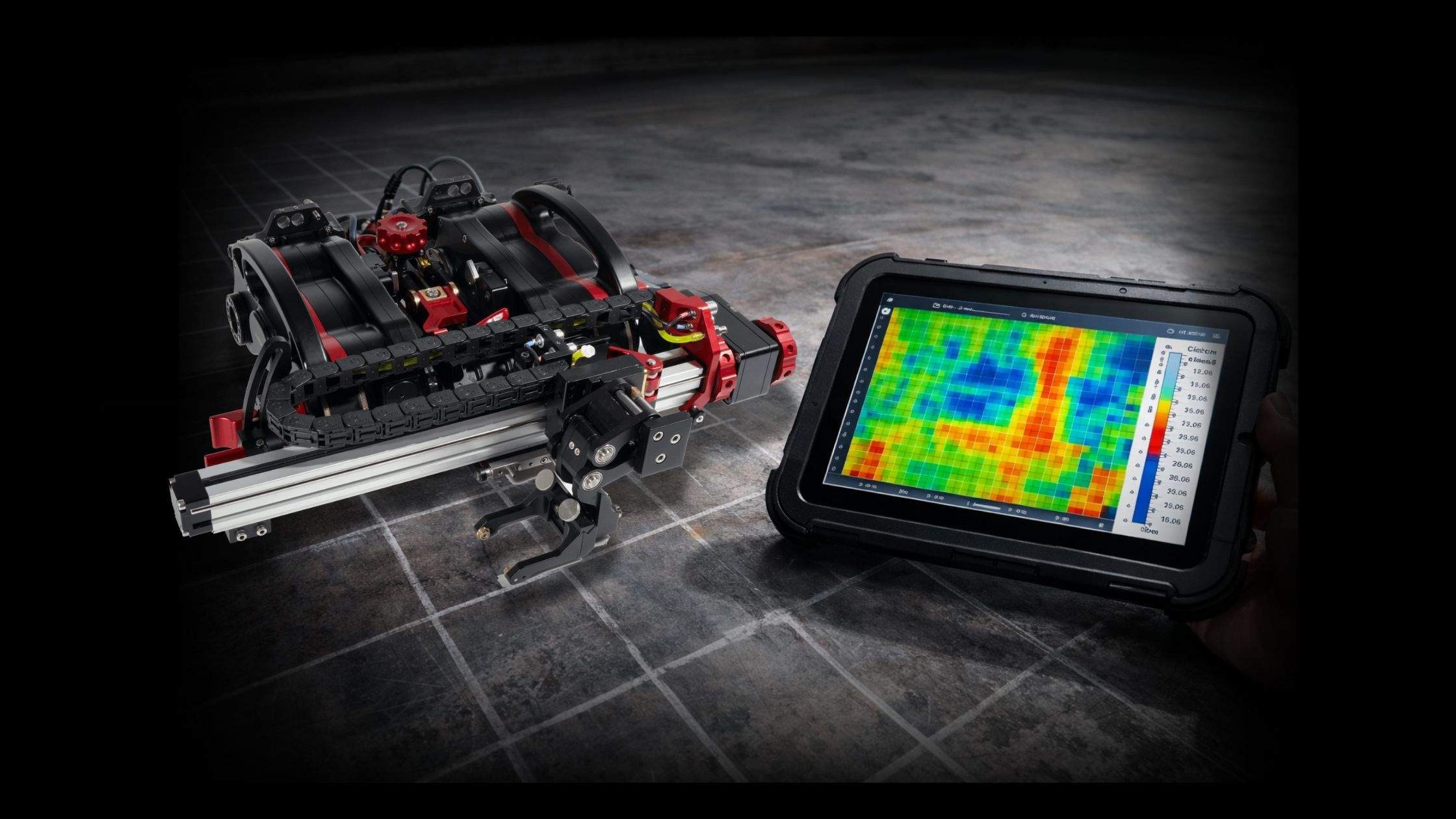

The Apex Modular Universal Scanner Platform from ScanTech is an ultrasonic inspection system designed for field adaptability and precision. It features a compact form factor, modular tool-less attachments, and high-speed raster capability to support various inspection tasks.

The Field Challenge

Inspection teams in oil & gas, petrochemical and power-generation environments face many types of assets: flat surfaces, small-diameter pipe, and vessel walls.

Often this means multiple scanners or frequent change-outs, which adds time, cost and complexity.

Field teams need one platform that adapts to many tasks while maintaining data reliability and minimizing downtime.

Introducing the Versatile Apex Scanner

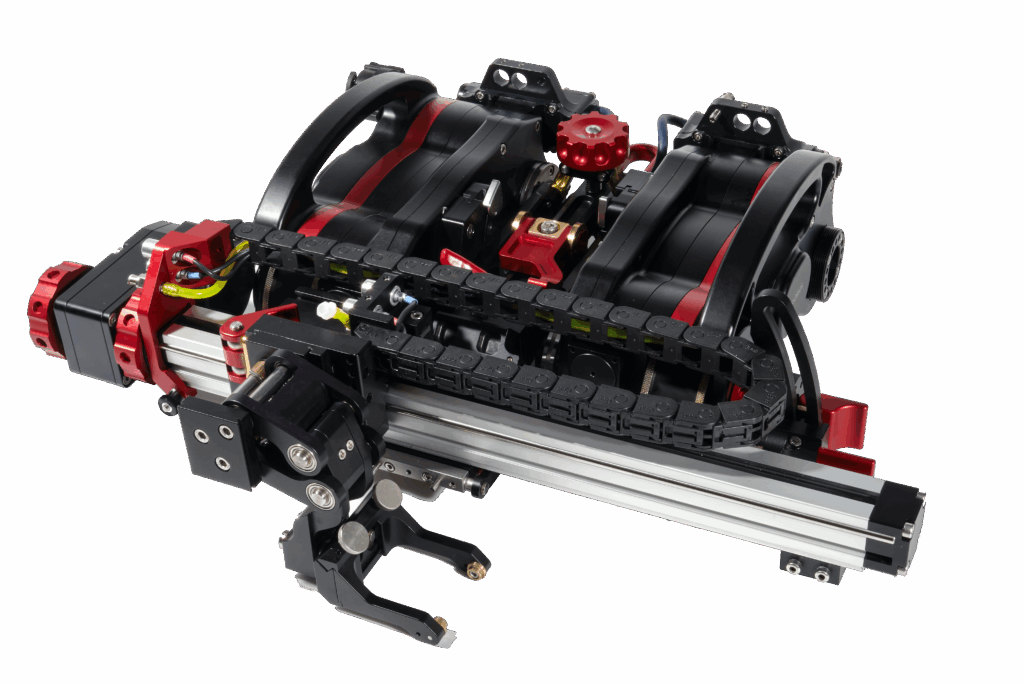

- ScanTech engineered Apex as a true modular universal scanner. It is compact (10.5″ length × 10.8″ width × 4.95″ height) and weighs just 19 lb.

- It supports multiple attachments including B-Scan and C-Scan.

- Maximum raster speed up to 30 in/sec (760 mm/sec).

- Minimum pipe diameters: circumferential with front raster arm 6″ OD; with side raster arm 3″ OD; axially 12″ OD with 9″ inspection width.

Designed for Modular Versatility

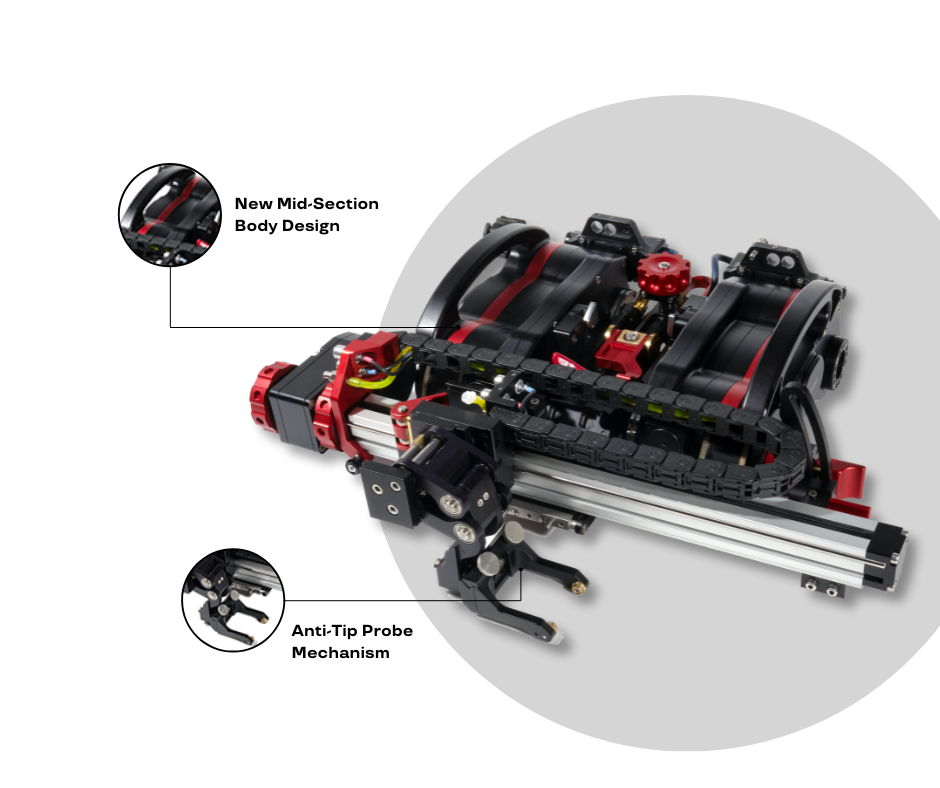

Apex’s key design features support adaptability:

-

- Tool-less attachment points allow rapid transition between modules.

- The anti-tip probe gimbal and near-constant-force spring assembly ensure stable probe contact and high signal return.

- Its distributed modular control system reduces umbilical complexity and simplifies upgrades.

Technicians can reconfigure between inspection types without tools. Managers can standardize on one platform across crews. Owners reduce equipment inventory and training overhead.

Efficiency for In Field Services

In testing and field comparisons; Apex demonstrated:

-

- The compact form factor and modular attachments reduced transport and setup time compared to bulkier systems.

- Raster arm speeds up to 30 in/sec allowed faster area coverage in corrosion mapping applications.

While every job differs, these specs illustrate how Apex is designed for productivity, not just capability.

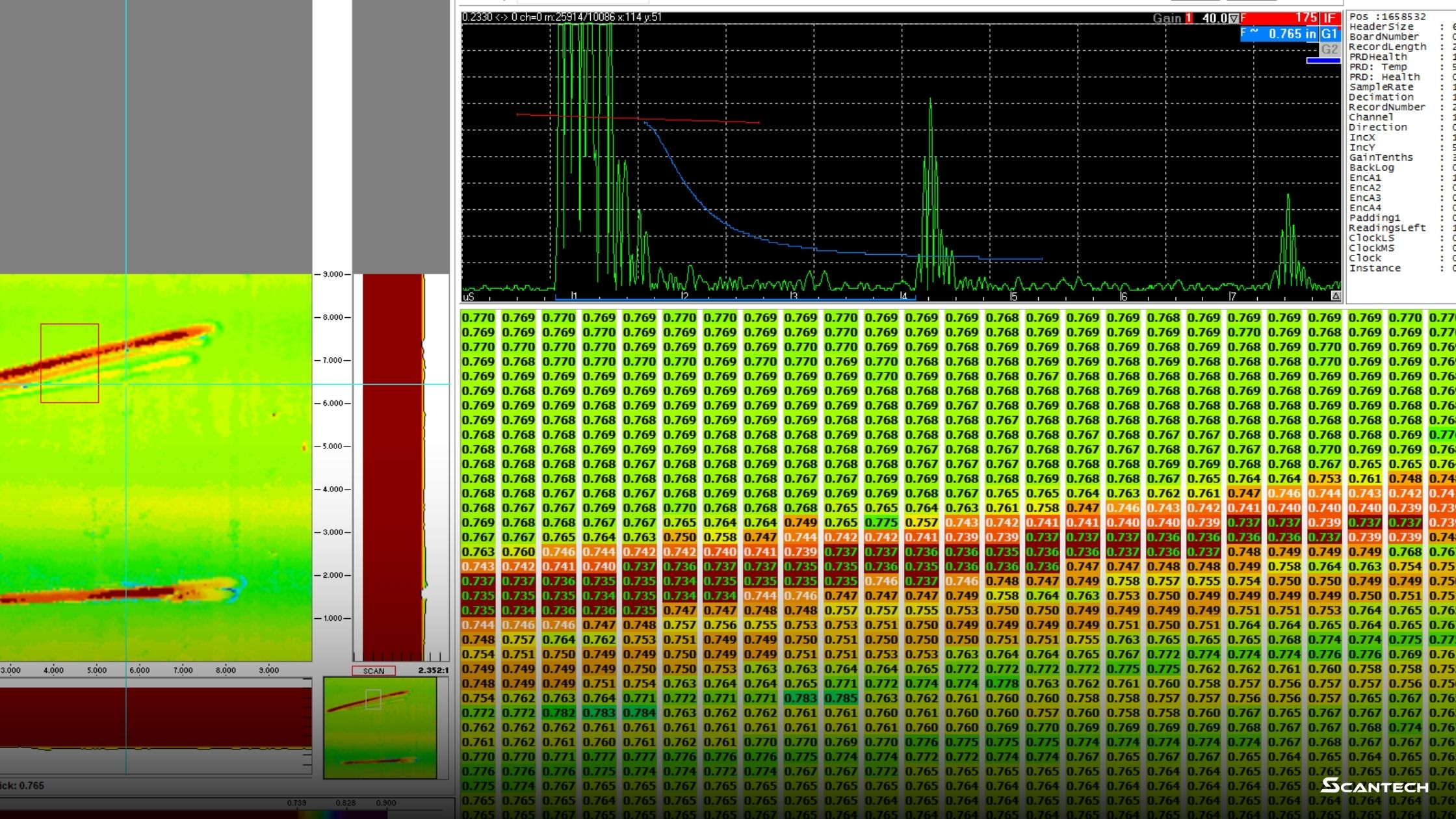

Software Integration and Data Quality

The Apex integrates seamlessly with ScanTech’s Analyst software suite. It supports real-time data acquisition and reporting for B-Scans (including API 653 Analysis) and for C-Scans (including ASME B316 workflows).

Consistent probe mechanics and sealed motion components contribute to repeatable data across job cycles and operators.

Built for Field Reliability

Every Apex unit is manufactured in ScanTech’s facility in Longview, Texas.

Field-tested components like sealed rotary bearings, high-torque drive units and tool-less module mounts ensure performance under challenging conditions.

When uptime matters, the details of build quality matter.

Ready to Upgrade Your Inspection Toolkit?

The Apex Modular Universal Scanner Platform is a field-ready solution that combines portability, modular versatility and precision mechanics. It supports a wide range of inspection tasks from corrosion mapping to inline B scanning while reducing asset diversity, set-up time and training needs. Built in Texas, engineered for the field and integrated with ScanTech software, Apex becomes a single platform for many inspection challenges.