Table of Contents

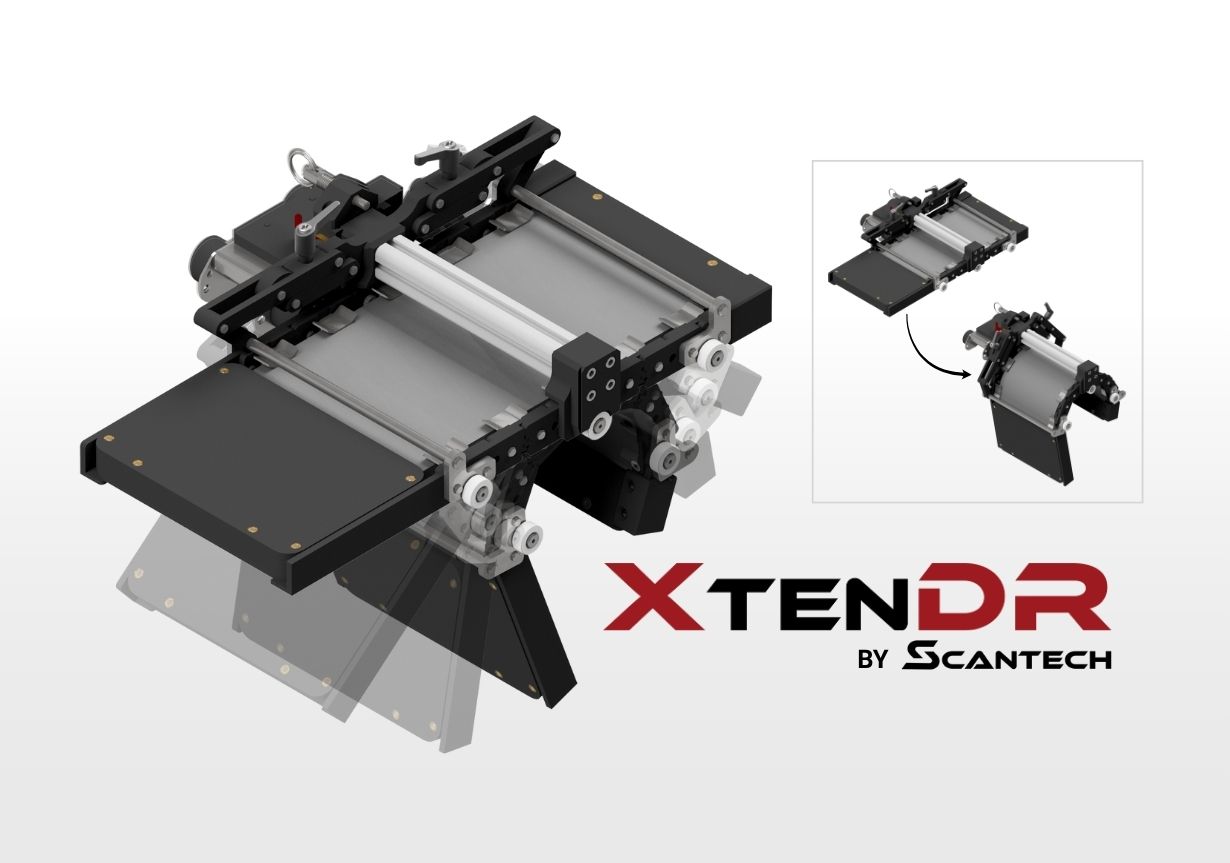

The XtenDR is a patented digital radiography (DR) panel holder engineered by ScanTech to prevent reverse bending and extend the operational life of flexible imaging panels.

By maintaining a constant bend radius and stable shape around curved geometries, XtenDR protects your most valuable inspection asset — your DR panel — while improving imaging consistency and field efficiency.

The Costly Problem Behind Every DR Inspection

Digital radiography panels are powerful — but fragile.

Every time a flexible DR panel is wrapped, bent, or repositioned on a pipe, internal stresses accumulate, shortening its usable life.

For inspection technicians, that means:

- Inconsistent image quality

- Reduced panel reliability

- Premature replacement costs

With inspection cycles tightening and budgets shrinking, protecting DR panels is no longer optional — it’s essential for maintaining performance and profitability.

Purpose-Built for Radiography Efficiency

The XtenDR was developed by ScanTech’s engineering team to maintain a consistent, repeatable panel shape around curved surfaces without stressing internal layers or cables.

Unlike improvised bungee straps or rigid clamps, the XtenDR uses a patented ARC Chain mechanism to form a controlled bend radius that prevents deformation and backward bending — the two leading causes of panel damage.

Core Advantages

- ARC Chain Design – Creates a perfect, constant bend radius to eliminate reverse bending and stress points.

- Set-It-Once Control – Locks into the desired curvature and maintains it through multiple shots.

- Faster Setup – Reduces repositioning time when imaging multiple welds or circumference segments.

- Built for Compatibility – Designed to integrate with ScanTech’s CLIX Modular Chain Scanner for radiographic applications.

Designed with the Inspector in Mind

In the field, every minute matters.

The XtenDR minimizes setup adjustments, allowing inspectors to maintain consistent panel placement across multiple shots; even in elevated or hard-to-reach areas.

For technicians, that means faster, safer scans and consistent panel curvature for every image.

For inspection managers, it reduces panel fatigue, maintenance costs, and downtime. This extends panel lifespan and improves ROI on high-value DR equipment.

Proven Results from Field Testing

In refinery and midstream applications, ScanTech recorded:

- Up to 3× longer panel lifespan when used with XtenDR versus manual bending.

- 30% faster average setup time between radiographic positions.

- Reduced image distortion and improved uniformity on curved surfaces.

Each XtenDR unit is precision-machined and assembled at ScanTech’s headquarters in Longview, Texas (5501 Innovation Circle), ensuring consistency across every build.

How It Works

At the heart of XtenDR is its ARC Chain geometry — a series of precision-linked segments that conform naturally to curved surfaces without over-flexing.

This design distributes load evenly along the panel’s surface, eliminating sharp curvature points that often cause cracking or delamination.

By maintaining this consistent radius:

- The panel’s internal components stay aligned.

- Image geometry remains uniform.

- The need for frequent re-bending or shape correction is eliminated.

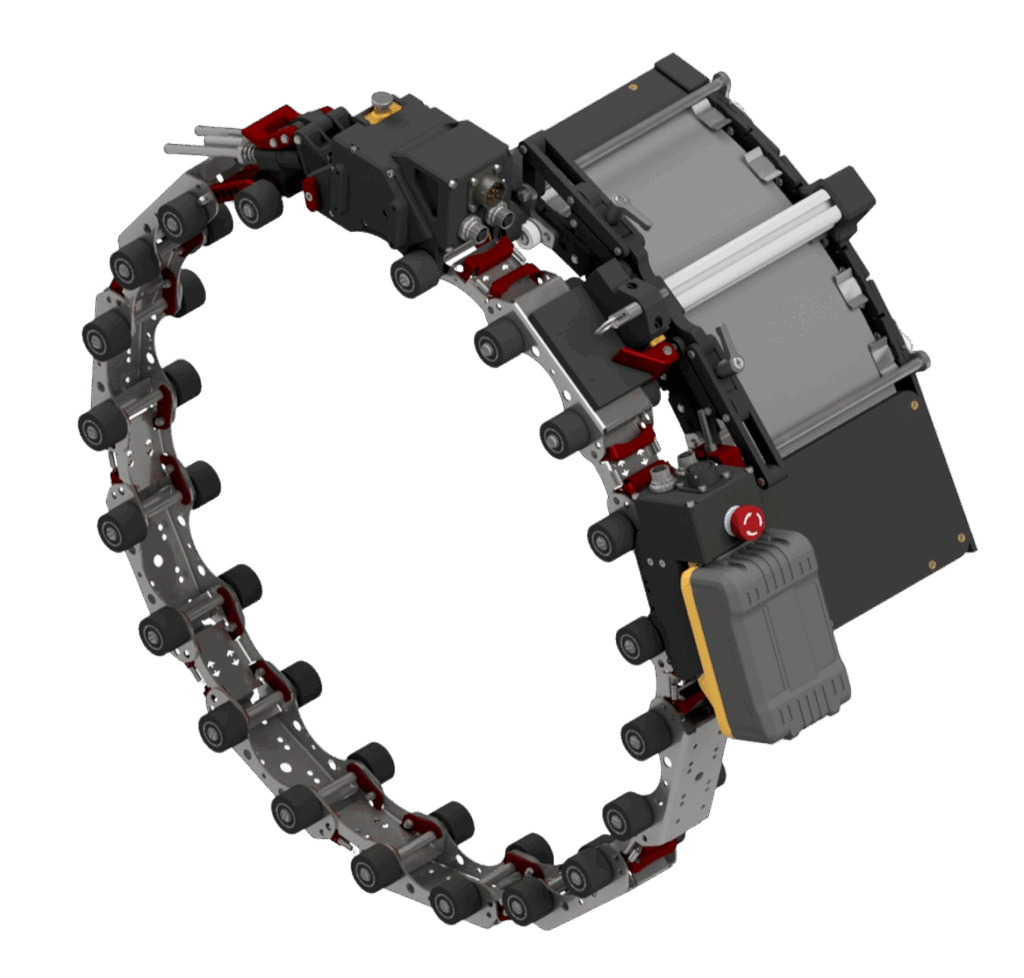

Pairing XtenDR with CLIX for Wireless RT

When paired with the CLIX-AW (Automated Wireless) chain scanner, XtenDR creates a complete wireless digital radiography workflow.

This setup enables remote positioning and imaging without panel handling during exposure, improving both safety and data quality.

Key Benefit:

Inspectors maintain complete control over imaging alignment while reducing risk to both the panel and operator. This makes it especially effective for elevated pipelines or confined refinery areas.

Explore More

- View the CLIX Modular Chain Scanner

- Download the XtenDR One-Pager (PDF)

- Explore All NDT Scanners

- Learn About Digital Radiography Applications

The XtenDR DR Panel Holder is a purpose-built solution that protects flexible digital radiography panels from premature wear.

By maintaining a controlled, repeatable curvature and reducing mechanical stress, it extends panel life and improves imaging consistency. The design also shortens setup times, giving inspectors a smarter and safer way to perform radiographic inspections in the field.

When paired with the CLIX Modular Chain Scanner, XtenDR delivers a new level of efficiency and precision for real-world NDT environments.