Table of Contents

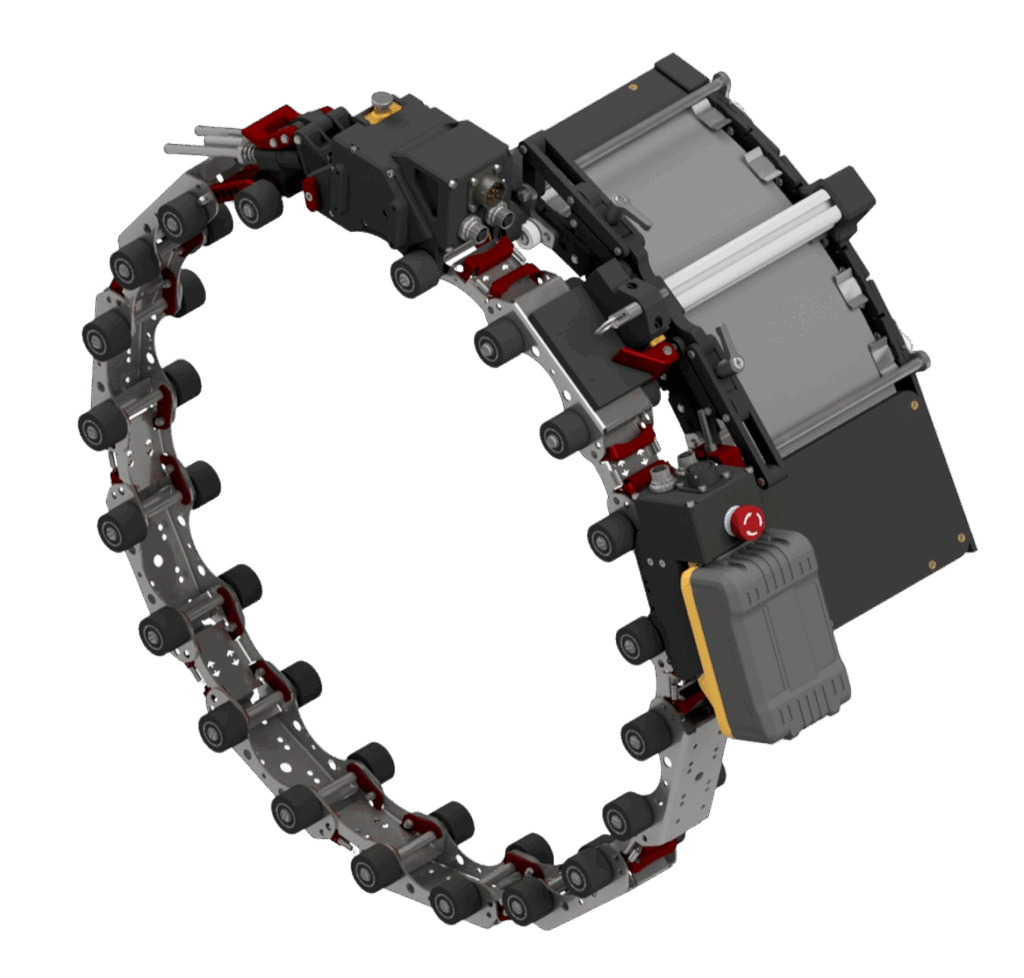

The CLIX Modular Chain Scanner is an adaptable, multi-method system engineered for ultrasonic and digital radiography inspections. Built with ScanTech’s Wheel Pack Assembly and modular chain link design, it delivers infinite scanning length, high payload capacity, and compatibility with both ferrous and non-ferrous surfaces — available in manual, automated, and fully wireless configurations.

Field Inspection Challenges in Multi-Method NDT

In oil & gas, power, and petrochemical environments, pipelines and vessels often require both ultrasonic thickness testing (UT) and digital radiography (RT) to validate weld integrity or detect corrosion.

Traditional scanners lock users into one inspection method, meaning operators must switch tools mid-job, increasing setup time, introducing misalignment, and doubling equipment transport.

Technicians need one system that can handle both methods — ultrasonic corrosion mapping and radiographic imaging — without re-rigging or losing scan repeatability.

For NDT Level III and inspection managers, that translates to fewer re-scans, less downtime, and unified data for compliance with API 650, API 653, and ASME B31G codes.

Introducing the CLIX System

Developed and manufactured in Texas, the CLIX Modular Chain Scanner combines mechanical precision, field durability, and cross-method adaptability in one platform.

Built around ScanTech’s patented Wheel Pack Assembly (WPA) and direct-drive design, CLIX provides smooth, slip-free travel across curved geometries — whether it’s positioned on a refinery pipe, a power plant header, or a vessel wall.

Available Kit Versions

| Version | Description | Application Focus |

|---|---|---|

| CLIX-MN | Manual control version | UT weld or corrosion inspection |

| CLIX-AU | Automated with umbilical control | UT corrosion mapping and weld scanning |

| CLIX-AW | Automated wireless kit | 100% wireless RT scanning and image acquisition |

Standard Kit Sizes

- 6–24″, 6–36″, and 6–48″ chain configurations

- Custom kits available for diameters above 48″

Multi-Method Inspection Flexibility

CLIX isn’t limited by inspection type — it’s optimized for multiple NDT modalities:

- Ultrasonic Testing (UT): For weld inspection, corrosion mapping, or thickness profiling using Analyst XR or Analyst X software.

- Radiographic Testing (RT): For digital imaging and wall-thickness verification when paired with ScanTech’s XtenDR™ panel holder for curved geometry stability.

- Combined Methods: For workflows requiring sequential UT and RT scans, the same scanner base can host both probe or panel holders with minimal configuration change.

Each CLIX link connects through the ARC Chain design to form a continuous, rigid path with infinite scanning length, maintaining consistent alignment for both UT and DR techniques.

Design Highlights

- Modular Construction: Easily reconfigurable for pipe size or inspection type.

- High Payload Capacity: Engineered for the added weight of digital radiography panels and accessories.

- Ferrous & Non-Ferrous Compatibility: Uses a hybrid magnetic / mechanical link system to maintain grip on any surface type.

- Wheel Pack Assembly (WPA): Provides constant-force probe or panel contact without manual adjustment.

- Wireless Operation (AW): Eliminates umbilical cords for fast deployment and improved safety in restricted areas.

- Cross-Platform Integration: Seamlessly pairs with Batt Pack Pro or Batt Pack Flex controllers for automated motion and data capture.

Proven Field Performance

- Infinite scan length capability — no limit on pipe circumference or vessel wall coverage.

- 30–40% faster setup versus segmented chain scanners.

- 100% wireless RT operation using the CLIX-AW and XtenDR™ system.

- Reusable across inspection types — reducing total cost of ownership.

In refinery and midstream applications, the CLIX system has been field-tested for both radiographic weld inspection and corrosion mapping, providing unmatched versatility across inspection teams.

Field Integration & Software Compatibility

The CLIX system integrates seamlessly with ScanTech’s Analyst Software Suite:

- Analyst XR for C-Scan corrosion mapping (with B31G analysis)

- Analyst X for B-Scan inspections (with API 653 report generation)

These software packages streamline data collection, visualization, and compliance reporting, ensuring every scan meets industry standards while minimizing manual input.

Built for Technicians. Backed by Engineers.

Like all ScanTech products, the CLIX Modular Chain Scanner is manufactured and assembled in-house at our Texas facility to maintain strict quality control and component precision.

Every detail — from the machined links to the sealed encoder housings — is engineered for reliability in the field.

The CLIX Modular Chain Scanner gives technicians a single, scalable platform for weld, corrosion, or digital imaging applications.

Explore More