Table of Contents

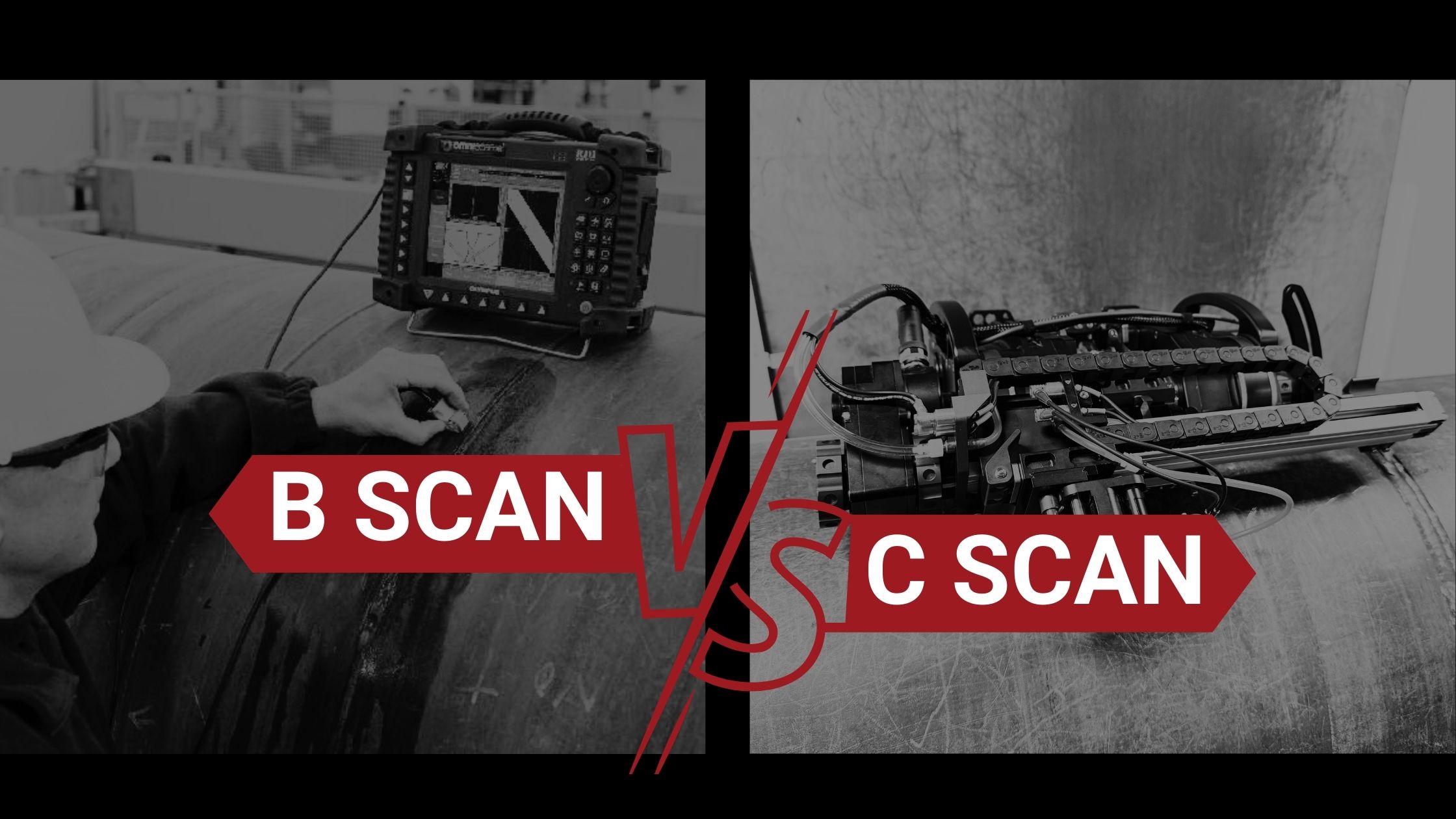

In ultrasonic testing (UT), data quality is non-negotiable. Whether you’re inspecting tank bottoms or monitoring corrosion across a large structure, choosing the right scanner is essential to getting accurate, actionable results.

Two of the most common UT scanning methods—B-scan and C-scan—are often confused or misapplied. But each serves a distinct purpose, and knowing the difference can save time, prevent reporting errors, and ensure compliance with inspection standards like API 653.

What Is a B Scanner?

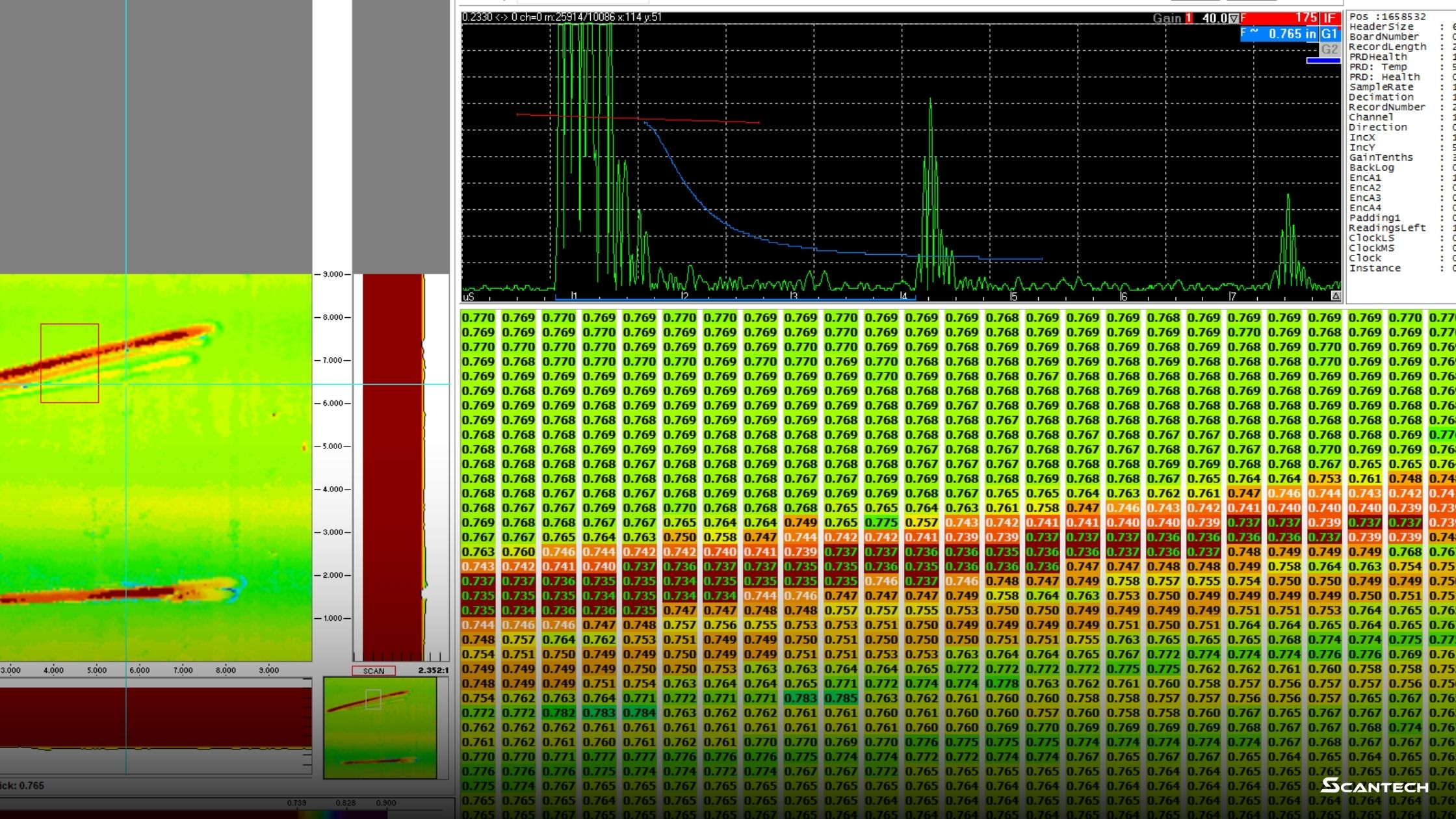

A B scanner captures a cross-sectional view of the material by moving the ultrasonic probe along a linear path. The resulting image displays variations in thickness and flaw depth along that scan line.

Best For:

- Thickness profiling

- Flaw sizing and mid-wall indication

- API 653 tank bottom inspections

- Welds, pressure vessels, and pipe walls

Why It Matters:

B-scan imaging is essential when the priority is identifying wall thinning, pitting, or other vertical anomalies that affect material integrity over a single axis.

Related Solution: ScanTech’s Axis Scanner and Analyst B-Scan Software are purpose-built for rapid thickness profiling with API 653-compliant reporting capabilities.

What Is a C Scanner?

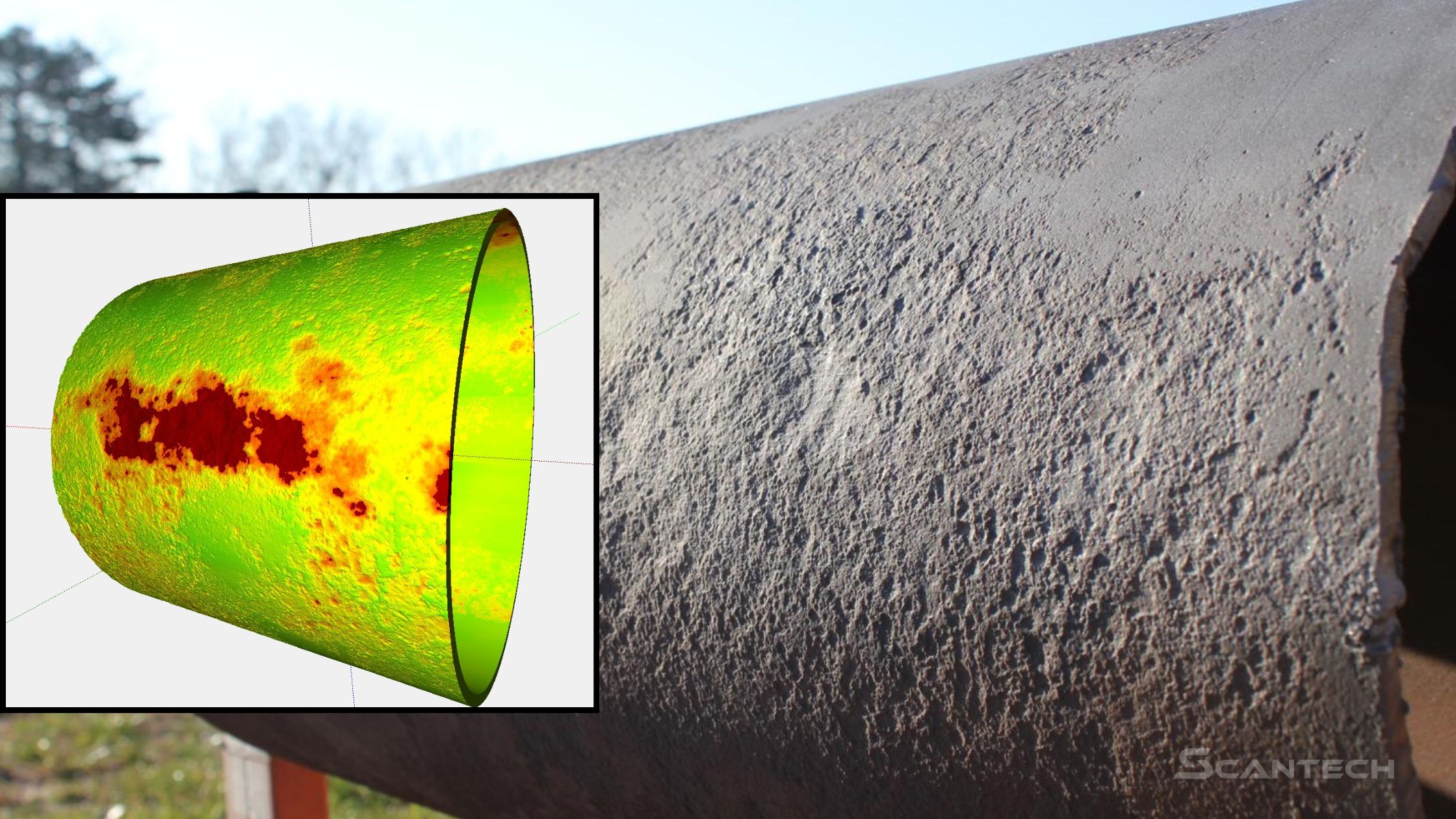

A C scanner produces a plan view (top-down) image by scanning across both the X and Y axes. It maps ultrasonic responses across a surface, displaying amplitude or time-of-flight data to show corrosion or material degradation across an area.

Best For:

- Full-surface corrosion mapping

- Wide-area condition assessments

- Tank shells, flat panels, and structural components

Why It Matters:

C-scanning is used strictly for corrosion mapping, not for vertical flaw sizing. It excels at identifying distributed material loss across large surface areas—not through-thickness defects.

Related Solution: ScanTech’s Vertex Scanner provides high-resolution area coverage with fast setup and detailed C-scan imagery for long-term asset monitoring.

B Scanner vs. C Scanner: Key Differences

| Feature | B Scanner | C Scanner |

| Scan Pattern | Single line (linear path) | Full surface area (2D map) |

| View | Cross-sectional (slice view) | Top-down (plan view) |

| Primary Use | Thickness profiling, flaw sizing | Corrosion mapping, flaw distribution imaging |

| Best For | Tank floors, pipes, welds | Tank walls, flat plates, structural panels |

| Setup Time | Faster and simpler | More setup required for full mapping |

| Data Detail | Depth changes along a line | Area-based variation and defect visualization |

When to Choose a B Scanner

Use a B scanner if:

- You need to generate cross-sectional thickness data

- You’re inspecting tanks under API 653 standards

- You’re focused on flaw sizing, wall thinning, or localized defects

- You require fast, portable setup in the field

Explore our Automated Tank Inspection Solutions

When to Choose a C Scanner

Use a C scanner if:

- You’re mapping corrosion across large surface areas

- You need a high-resolution plan view of degradation

- The goal is asset monitoring over time—not flaw sizing

- Your inspection involves flat or curved panels, not pipes

Learn more about our Corrosion Mapping Capabilities

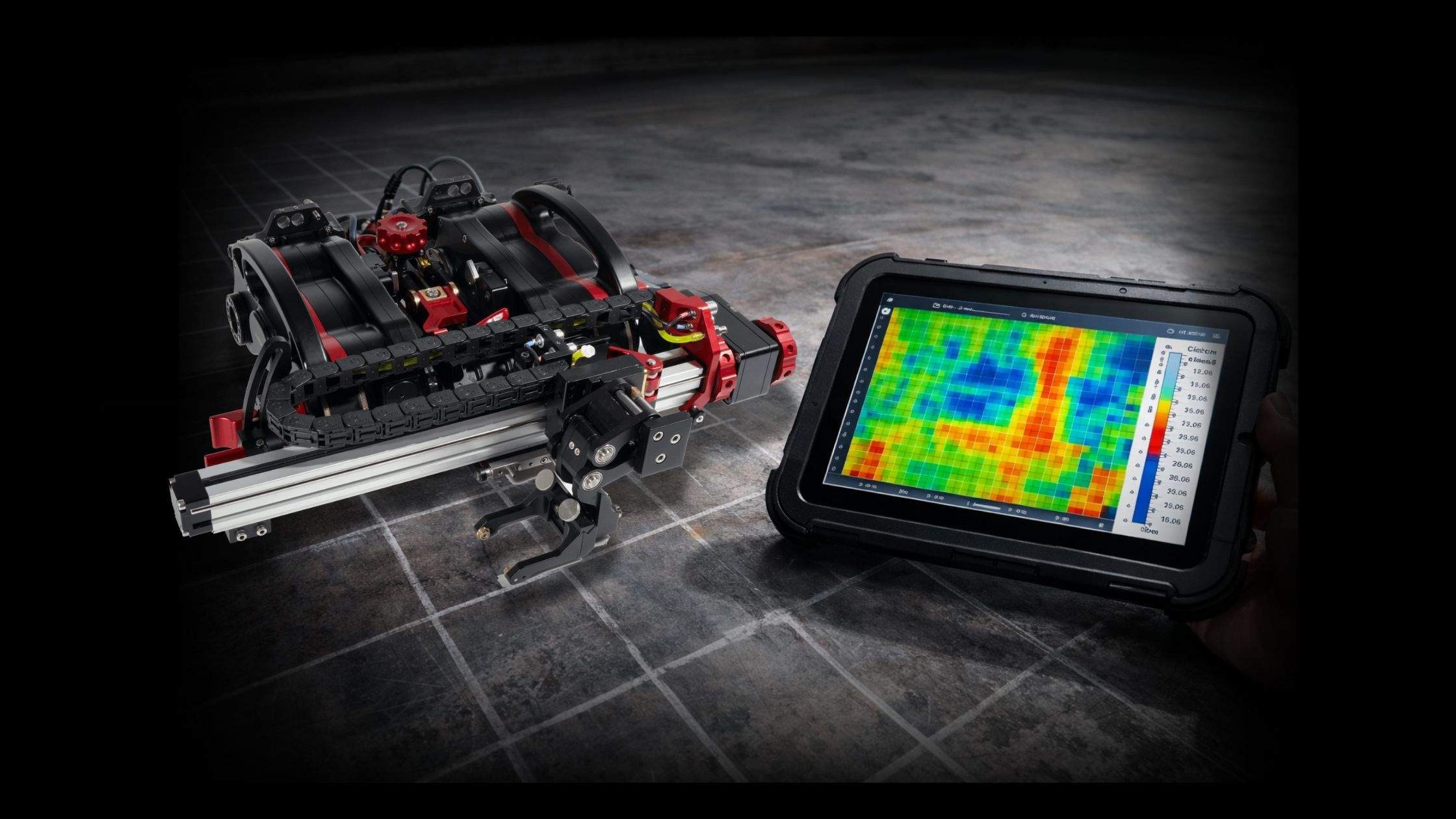

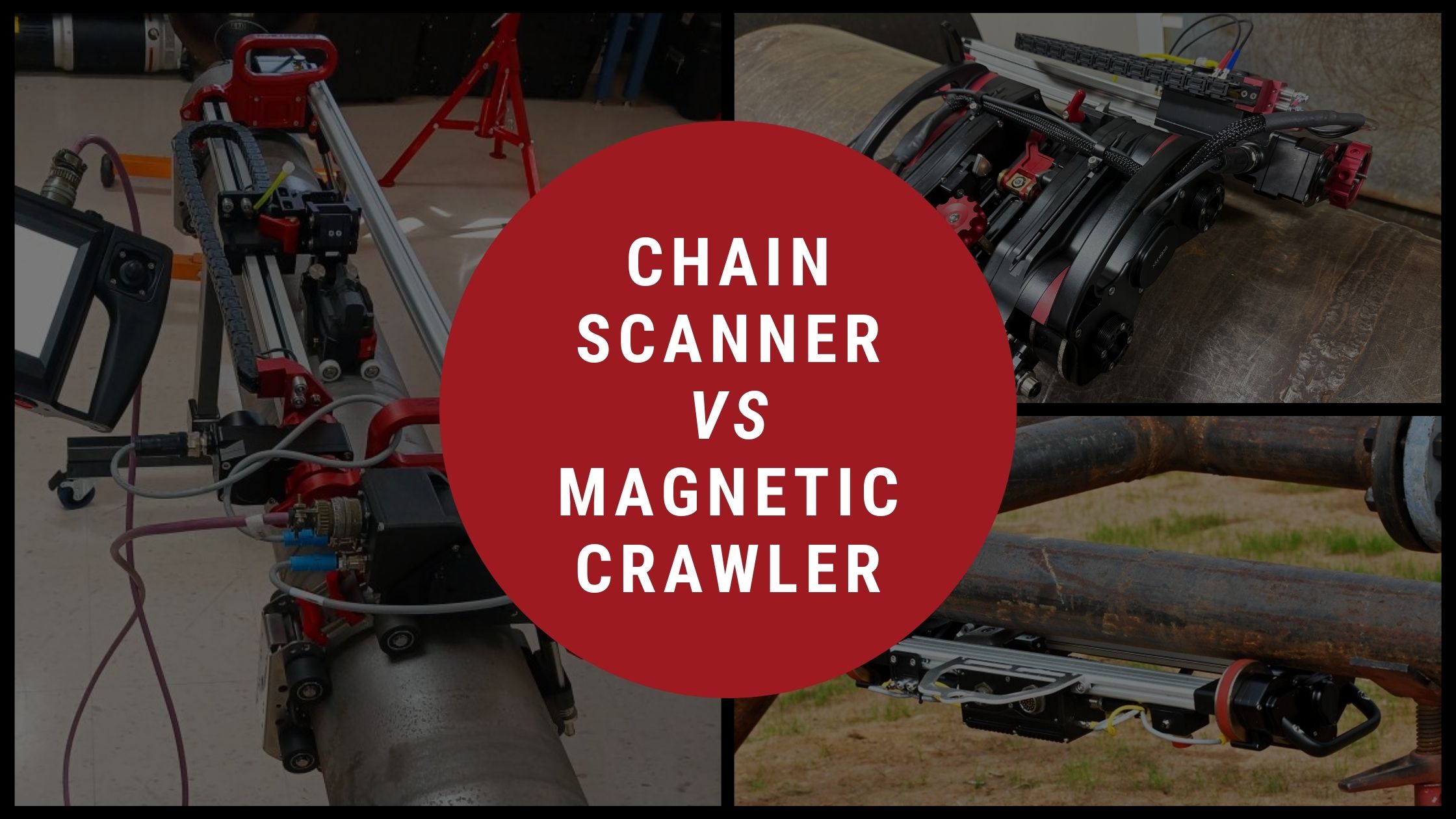

ScanTech Systems for Each Method

At ScanTech, we don’t believe in one-size-fits-all. Each of our systems is designed for specific scanning methods and real-world application demands:

- Axis Scanner + Batt Pack – Ideal for B-scan inspections on tank bottoms, vessels, and welds

- Vertex or XR Spider – Optimized for high-resolution C-scan corrosion mapping

- Analyst Software – Built-in API 653 algorithms, real-time data, and fast report generation for inspectors in the field

Conclusion: Use the Right Scanner for the Right Job

B scanners and C scanners are not interchangeable—they’re engineered for different tasks. If you’re inspecting tank floors, welds, or any asset under API 653, you need a B scanner. If you’re mapping large surfaces for widespread corrosion, the C scanner is the right tool.

Choosing the correct scanner ensures better data, faster inspections, and more accurate reports. Still not sure what fits your application?

Talk to a ScanTech expert for help building the right system for your inspections.

FAQ's

No. API 653 requires thickness data typically collected via B-scanning, not surface-level imaging.

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in Bookmarksgrove right at the coast

A B scanner like the Axis is ideal for quick inspections in confined spaces due to its streamlined setup and encoded scanning path.