Table of Contents

In industries like oil and gas, power generation, and manufacturing, maintaining the health of infrastructure is critical to ensure safety, compliance, and long-term reliability. Over time, pipelines, storage tanks, and other essential assets undergo wear and tear that can lead to failures if left unmonitored. Nondestructive Testing (NDT) has become an invaluable approach for assessing infrastructure without causing any damage. Not only does NDT protect these critical assets, but it also reduces maintenance costs, enhances safety, and extends the life of equipment.

In this article, we’ll look at how NDT supports infrastructure health, prevents expensive breakdowns, and saves money across industries. We’ll also highlight the advantages of using tools like the BPS System Power Pack for on-site NDT inspections and explore how built-in API 653 reporting in our software simplifies compliance and boosts efficiency.

Why NDT Is Crucial for Infrastructure Maintenance

Industrial assets, especially those exposed to harsh conditions, face constant risks of degradation. Traditional maintenance methods often require shutdowns, disassembly, or other time-consuming steps to inspect equipment. By contrast, NDT techniques allow inspectors to assess asset health without interrupting operations, minimizing downtime and cutting costs.

Key Benefits of NDT in Industrial Maintenance

- Extends Asset Life: NDT helps catch early signs of wear, corrosion, and other issues, allowing companies to perform preventive maintenance before damage becomes severe.

- Reduces Maintenance Costs: By identifying and fixing problems early, NDT lowers the need for major repairs or replacements.

- Boosts Safety and Compliance: Routine NDT inspections help companies meet industry standards, like API 653, which focuses on the inspection and maintenance of above-ground storage tanks.

- Improves Operational Efficiency: Since NDT does not require disassembly, inspections are faster and less disruptive to operations.

If you’re looking to enhance asset reliability, learn more about our BPS System Power Pack for on-site NDT inspections.

How NDT Techniques Enhance Infrastructure Longevity

NDT offers a range of techniques that can detect both internal and surface flaws in materials, from metal to composites. Let’s look at some of the most common methods used for industrial maintenance.

Ultrasonic Testing (UT)

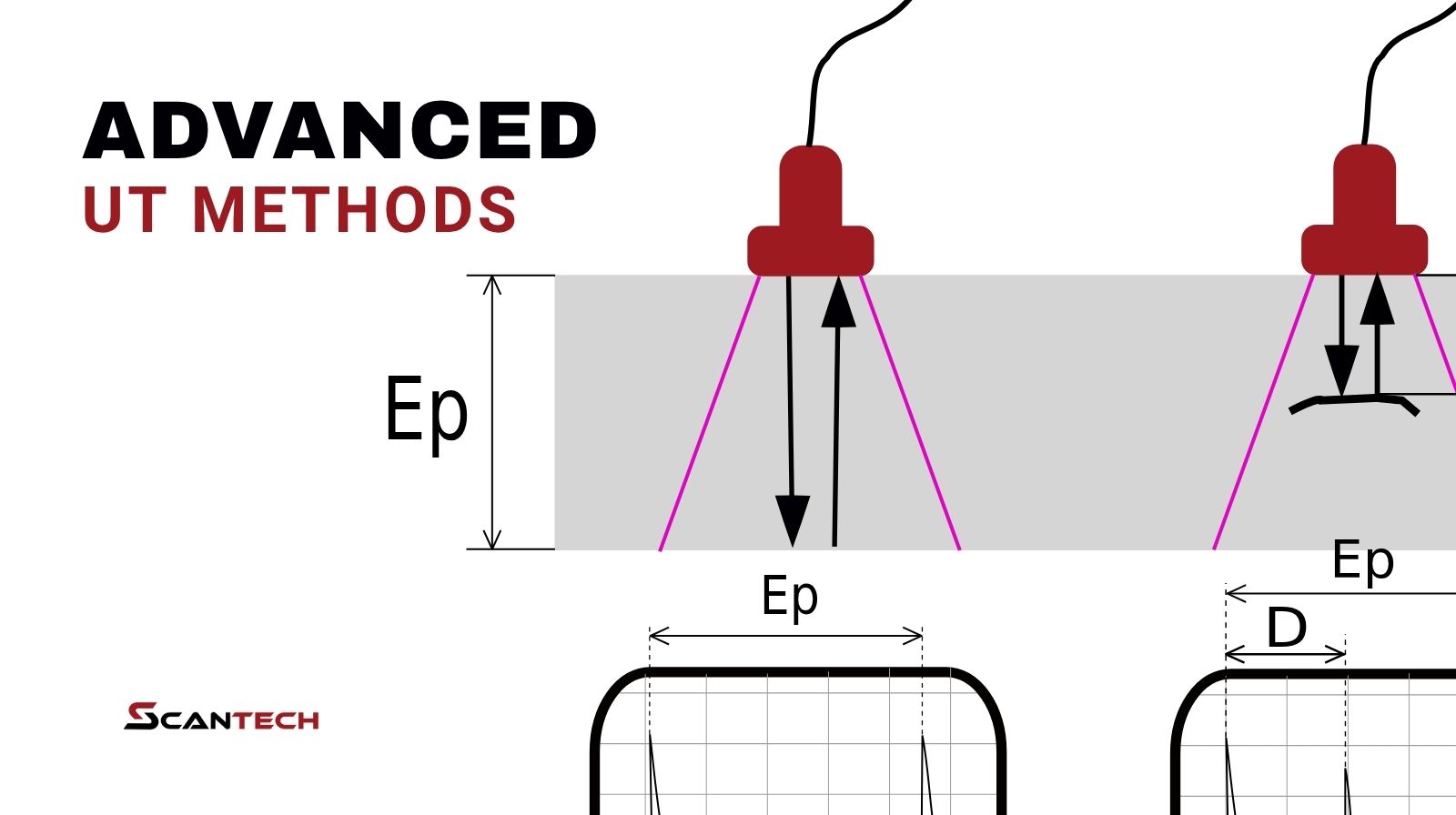

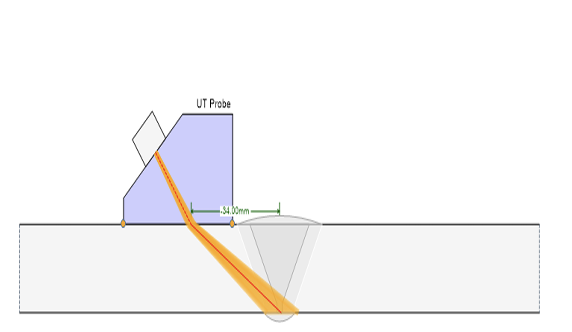

Ultrasonic testing is one of the most widely used NDT methods. This method sends high-frequency sound waves into a material. If there’s a crack or corrosion, the waves reflect back to the transducer, helping inspectors locate and assess the flaw. Ultrasonic testing is ideal for detecting internal defects and can be automated with ultrasonic scanners to cover large areas efficiently. This makes UT a top choice for inspecting pipelines, storage tanks, and critical support structures.

Radiographic Testing (RT)

Radiographic testing uses X-rays or gamma rays to reveal defects inside materials, making it useful for inspecting welds, pipelines, and pressure vessels. RT provides insight into internal cracks and inclusions that could weaken structures. However, this method requires strict safety protocols due to radiation, so it’s best suited for controlled environments.

Magnetic Particle Testing (MT)

Magnetic Particle Testing is quick and reliable for detecting surface and near-surface defects in metals. By magnetizing the material and applying a magnetic particle solution, inspectors can see clusters where there are cracks or flaws. MT works well for inspecting welds and joints in steel structures.

Visual Testing (VT)

Though basic, visual testing is a valuable NDT technique, especially when paired with other methods. Inspectors visually examine surfaces for corrosion, deformation, or other signs of wear, allowing them to prioritize areas that may need further testing.

Each of these techniques contributes to asset longevity by identifying potential issues early. With regular NDT inspections, companies can extend the life of their equipment, reduce maintenance costs, and improve safety.

NDT and Cost Savings: Lowering Maintenance Expenses and Downtime

NDT isn’t just about compliance and safety—it’s also a powerful tool for cutting costs. Here’s how NDT supports financial savings:

- Proactive Maintenance: NDT allows early detection, so companies can perform repairs before damage escalates. This proactive approach is often less expensive than emergency fixes.

- Less Downtime: NDT inspections are quick and noninvasive, which means less downtime. Keeping operations running translates into higher productivity and lower costs.

- Reduced Equipment Replacements: Routine NDT extends the life of high-cost assets, like storage tanks and pipelines, so companies don’t need to replace them as often.

- Standards Compliance: Compliance with standards like API 653 helps avoid costly fines and penalties. Our software offers built-in API 653 reporting to simplify this process, which saves time and money on data entry and analysis.

For further details on how we support API 653 compliance, check out our API 653 reporting software.

Featured Tool: BPS System Power Pack for On-Site NDT Inspections

The BPS System Power Pack is a reliable solution for on-site NDT inspections. Built for durability, it’s especially suited for harsh environments. The BPS System Power Pack supports various NDT methods, including ultrasonic testing, magnetic particle testing, and visual inspections. It’s designed for flexibility, allowing inspectors to carry out thorough evaluations without being limited by power constraints or equipment mobility.

In addition, the BPS System Power Pack integrates seamlessly with the WS3 Couplant Delivery System to ensure smooth and consistent testing. Its portability makes it easy to access hard-to-reach areas and is ideal for large or complex structures.

API 653 Reporting for Simplified Compliance and Cost Savings

For industries that rely on above-ground storage tanks, compliance with API 653 standards is crucial. API 653 outlines requirements for the inspection, repair, and maintenance of storage tanks to ensure safe, reliable operation. Yet, keeping up with these reporting requirements can be time-consuming and prone to errors.

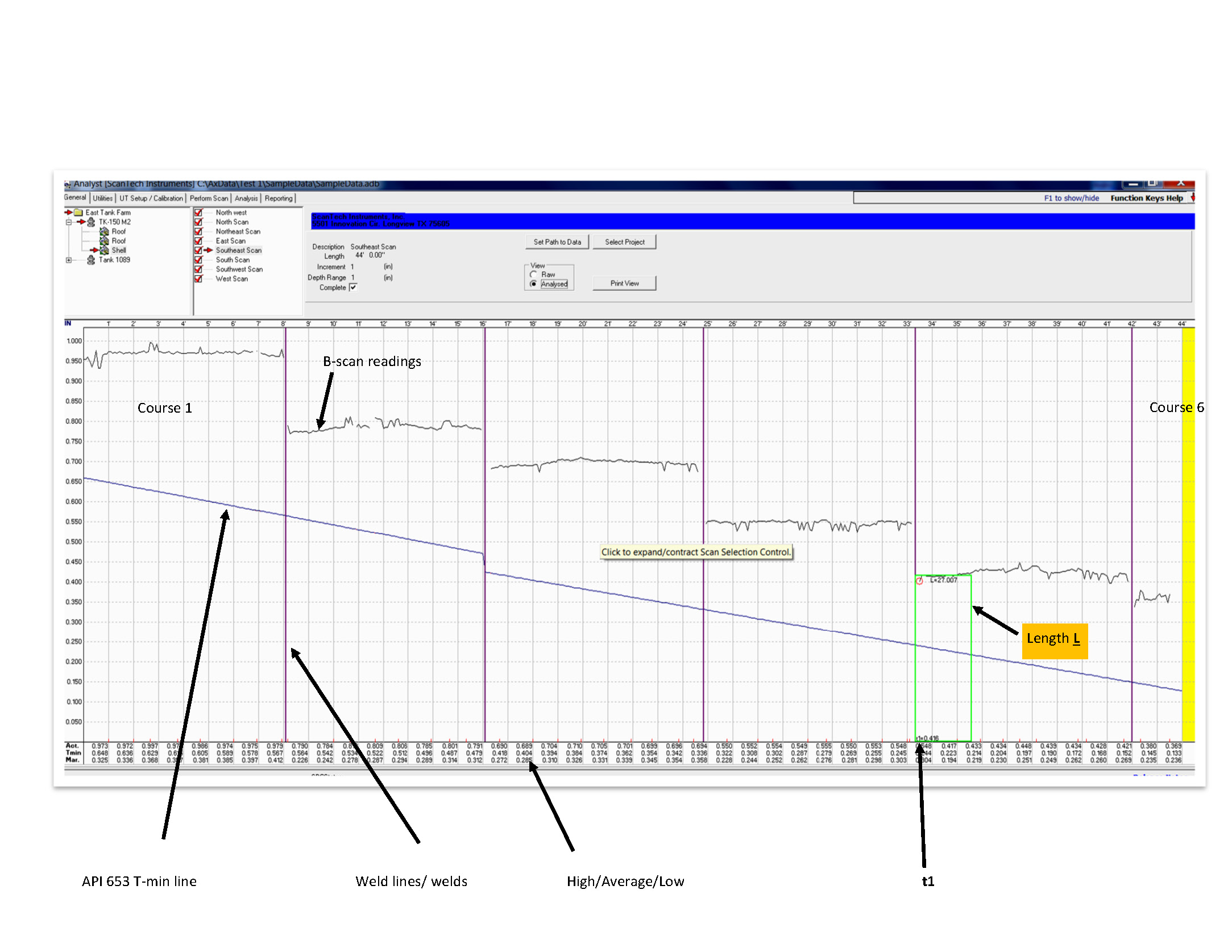

Our NDT software offers built-in API 653 reporting capabilities to simplify this process. With automated API 653 reporting, inspectors can capture and organize data quickly. The system generates reports that meet API 653 standards, which not only saves time but also reduces the risk of manual errors. Ultimately, automated API 653 reporting leads to significant cost savings by streamlining compliance and reducing administrative work.

The Future of NDT in Industrial Maintenance

As industries face higher demands for safety, efficiency, and reliability, NDT will continue to play a key role in industrial maintenance. With the rise of automation and advanced software solutions, NDT is becoming even more accurate, accessible, and cost-effective. By investing in tools like the BPS System Power Pack and our built-in API 653 reporting system, companies can adopt a proactive maintenance strategy. This approach extends asset life, reduces unexpected failures, and enhances operational safety.

In the end, NDT is about much more than faster inspections. It’s about giving industries a powerful way to protect their most critical assets, maintain safety, and realize long-term savings.