Ultrasonic inspection is a critical method for ensuring the integrity of materials and structures. However, many NDT companies face challenges that can compromise the efficiency and accuracy of their inspections. At ScanTech Instruments, we’ve designed our scanners to address these pain points, helping inspection teams deliver better results with less hassle.

Common Challenges in Ultrasonic Inspection

1. Environmental Conditions

From extreme temperatures to high humidity, environmental factors can significantly impact the

performance of inspection equipment.

Solution:

ScanTech’s scanners are built with rugged, sealed designs that resist environmental contaminants, ensuring consistent performance even in harsh conditions.

2. Limited Tool Adaptability

Many inspection tools are limited in their ability to handle different materials or configurations, requiring multiple systems for various applications.

Solution:

Our scanners feature modular components, allowing for quick adjustments to accommodate different inspection needs without additional equipment.

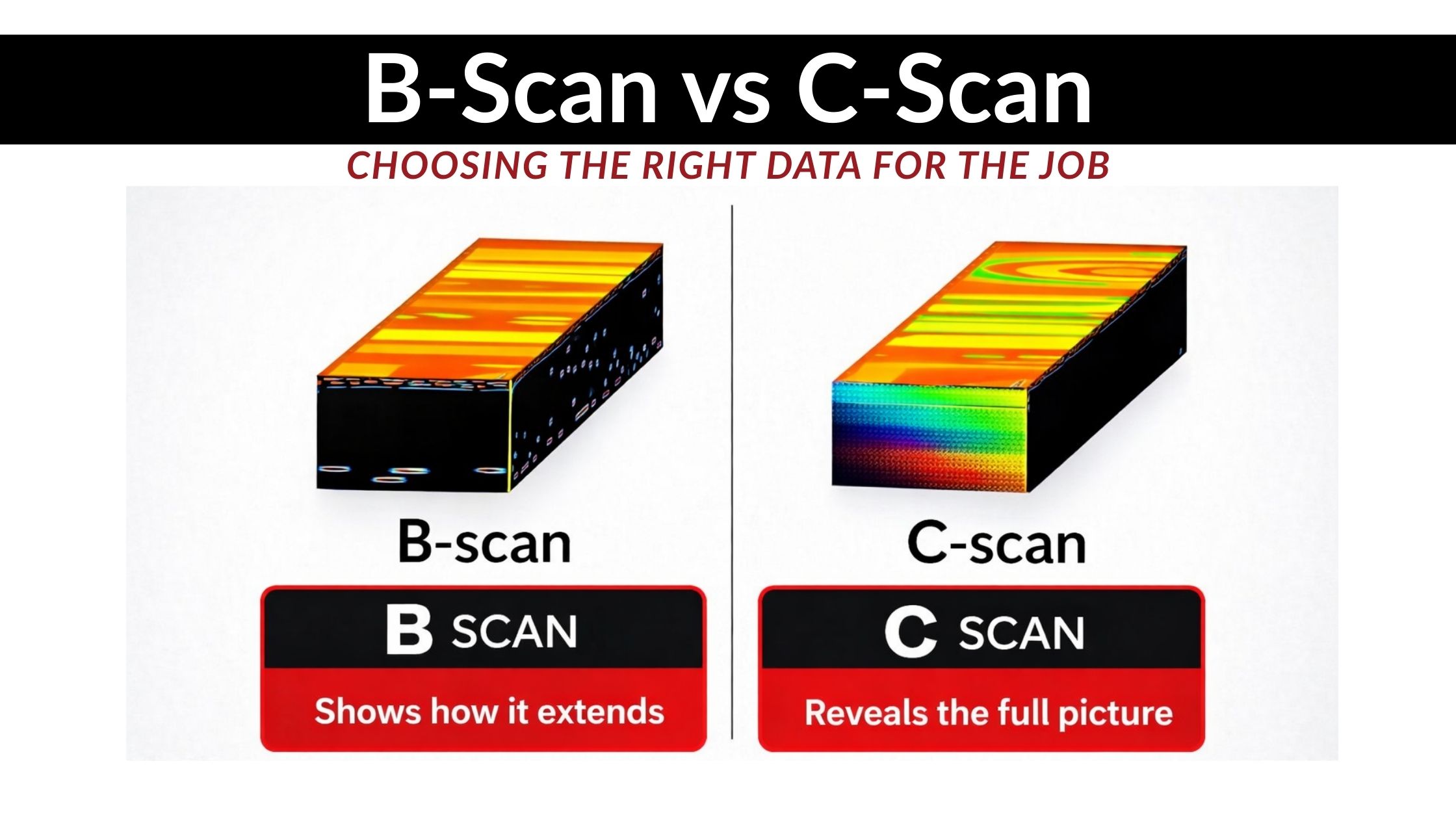

3. Data Accuracy and Accessibility

Inaccurate or incomplete data can lead to costly errors and safety risks.

Solution:

ScanTech’s scanners integrate with Analyst Software, providing high-resolution imaging and real-time data reporting to eliminate guesswork.

How ScanTech Scanners Solve These Issues

1. Versatility Across Applications

Whether it’s weld inspections, corrosion mapping, or pipeline evaluations, our scanners are designed to excel in a wide range of applications, eliminating the need for specialized tools.

2. Reduced Setup Time

With easy-to-use interfaces and minimal calibration requirements, our scanners help inspection teams save valuable time in the field.

3. Reliability You Can Count On

Every ScanTech scanner is rigorously tested to ensure durability and performance, so you can focus on the job without worrying about equipment failures.

Why Choose ScanTech for Ultrasonic Inspection?

At ScanTech Instruments, we prioritize the needs of inspection companies and NDT service providers. Our scanners are engineered to address the real-world challenges you face, helping you improve efficiency, reduce costs, and deliver superior results.

FAQs About Ultrasonic Inspection

What makes ScanTech’s scanners different from other ultrasonic equipment?

Our scanners are designed with modularity, durability, and advanced software integration, making them adaptable to various applications and environments.

Can ScanTech’s scanners handle extreme environments?

Absolutely! Our rugged designs are built to withstand tough industrial conditions, ensuring reliable performance in any setting.

Do you offer training for your equipment?

Yes, we provide comprehensive training to ensure your team can operate our scanners with confidence and efficiency.